Method for preparing lead selenide film by using microwave plasma chemical vapor deposition technology

A technology of microwave plasma and chemical vapor deposition, which is applied in the field of infrared detection, can solve problems such as device manufacturing uncertainty, achieve high stability and repeatability, facilitate experimental operation and experimental control, and simplify processing steps.

Active Publication Date: 2020-12-01

CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI +1

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the disagreement on the clarification of the sensitization mechanism has persisted for a long time, which may bring uncertainty to the fabrication of such devices

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

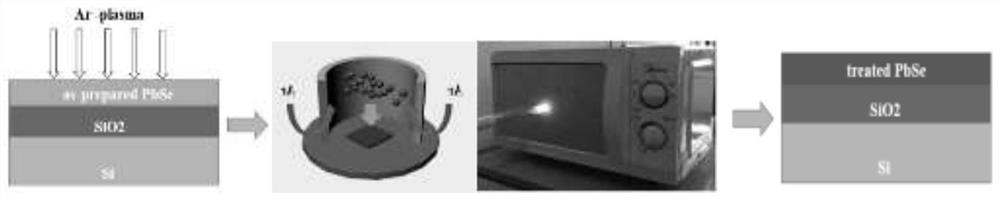

[0030] Embodiment 1 prepares PbSe film

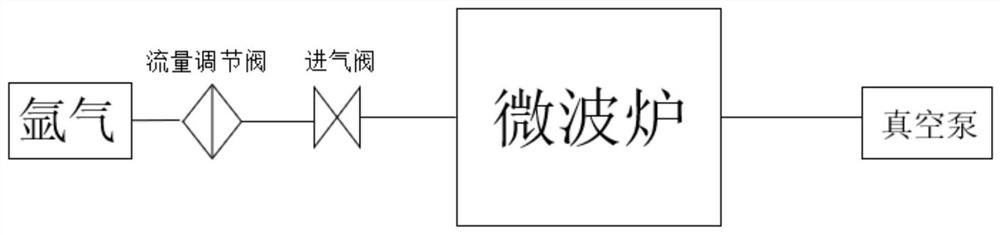

[0031] refer to figure 1 , is a schematic diagram of the self-made MPCVD system. The system consists of a household microwave oven (power set to 700w), a gas supply system, a quartz tube (outer diameter 25mm) and a vacuum pump. The gas supply system includes argon, a flow control valve and an inlet valve. .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

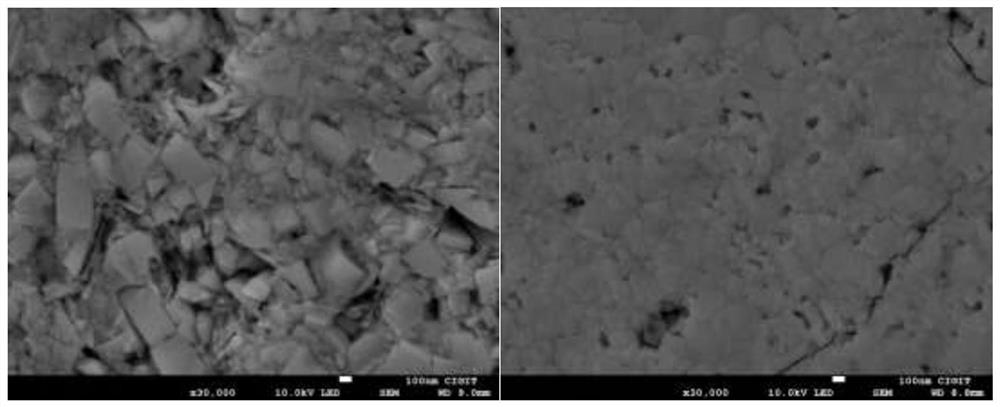

The invention belongs to the technical field of infrared detection, and relates to a method for preparing a lead selenide film by using a microwave plasma chemical vapor deposition technology. The method comprises the following steps: (1) growing a lead selenide film on a substrate by adopting a thermal evaporation technology; and (2) treating the lead selenide film by adopting the microwave plasma chemical vapor deposition technology. The microwave plasma treatment technology does not cause selenium element loss, and does not change element composition or material properties of raw materials,the crystallization degree is improved only through the sintering phenomenon, and the photoelectric property is enhanced.

Description

technical field [0001] The invention belongs to the technical field of infrared detection, and relates to a method for preparing a lead selenide thin film by using a microwave plasma chemical vapor deposition method. Background technique [0002] Lead selenide (PbSe) is a typical narrow-band semiconductor material with an absorption range of 3-30um, which corresponds to the mid-to-far infrared absorption range, and is widely used in infrared detectors, solar cells, laser diodes and other fields. In recent years, lead selenide thin films have been widely used due to their narrow bandwidth (E F =0.278ev), high quantum efficiency, high photoelectric sensitivity, and good stability at room temperature, etc., which have attracted widespread attention. Generally, the composition and microstructure of PbSe thin films can be changed by changing the preparation method and corresponding parameters. At present, PbSe thin films have been successfully prepared by various chemical, elec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L21/02C23C16/30C23C16/48

CPCH01L21/0256H01L21/0262C23C16/306C23C16/486

Inventor 于乐泳冯双龙魏兴战史浩飞

Owner CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com