Acid-resistant and alkali-resistant pure titanium composite pot and processing method thereof

A technology of acid and alkali resistance and processing method, which is applied in special materials of cooking utensils, the structure of cooking utensils, cooking utensils, etc., can solve the problems of insufficiency of acid and alkali resistance of the pot body, achieve excellent acid and alkali resistance, and improve the density. , Improve the effect of acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

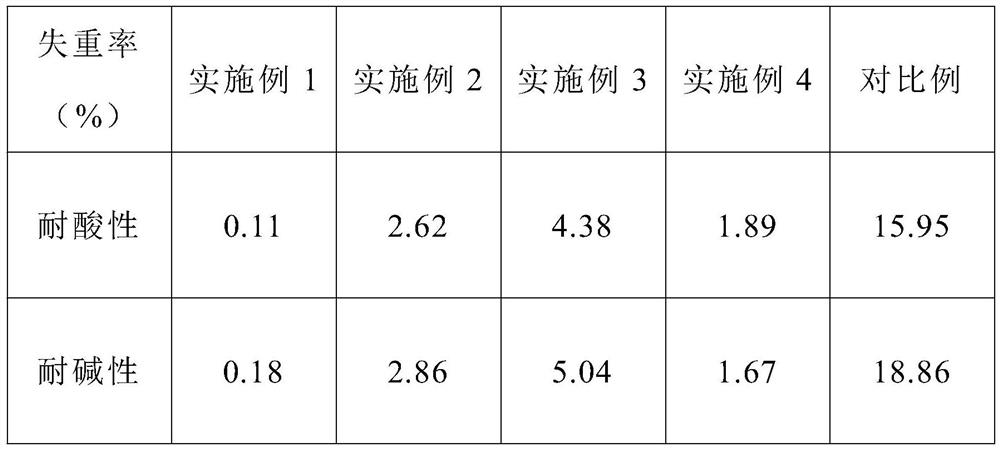

Examples

Embodiment 1

[0036] An acid and alkali resistant pure titanium composite pot mainly includes the following raw material components in parts by weight: 20 parts of modified titanium plate, 10 parts of graphene, 3 parts of urea and 8 parts of potassium tetratitanate.

[0037] A method for processing an acid and alkali-resistant pure titanium composite pot, the processing method of the acid and alkali-resistant pure titanium composite pot mainly includes the following preparation steps:

[0038] (1) Mix the titanium plate and mixed acid at a mass ratio of 1:8, wash at room temperature for 10 minutes, and filter to obtain an acid-washed titanium plate blank, and dry the pickled titanium plate blank at a temperature of 80°C for 3 hours, To obtain an acid-washed titanium plate, place the pickled titanium plate in 10% sodium bromide solution, carry out constant current anodic etching at a temperature of 0°C, and filter it after 5 minutes, and place it in a temperature of 80°C Dry for 2 hours unde...

Embodiment 2

[0048] An acid and alkali resistant pure titanium composite pot mainly includes the following raw material components in parts by weight: 20 parts of modified titanium plate, 10 parts of graphene, 3 parts of urea and 8 parts of potassium tetratitanate.

[0049] A method for processing an acid and alkali-resistant pure titanium composite pot, the processing method of the acid and alkali-resistant pure titanium composite pot mainly includes the following preparation steps:

[0050] (1) Mix the titanium plate and the mixed sol at a mass ratio of 1:10, soak at room temperature for 60 minutes, filter to obtain a filter cake, and calcinate the filter cake at a temperature of 600°C for 3 hours;

[0051] (2) Mix and grind potassium carbonate and titanium dioxide at a molar ratio of 1.5:4.0 to obtain a mixed powder, and calcinate the mixed powder at a temperature of 800°C for 24 hours to obtain potassium tetratitanate powder, and use the potassium tetratitanate powder After washing wit...

Embodiment 3

[0057] An acid and alkali resistant pure titanium composite pot mainly includes the following raw material components in parts by weight: 20 parts of modified titanium plate, 10 parts of graphene, 3 parts of urea and 8 parts of potassium tetratitanate.

[0058] A method for processing an acid and alkali-resistant pure titanium composite pot, the processing method of the acid and alkali-resistant pure titanium composite pot mainly includes the following preparation steps:

[0059] (1) Mix the titanium plate and mixed acid at a mass ratio of 1:8, wash at room temperature for 10 minutes, and filter to obtain an acid-washed titanium plate blank, and dry the pickled titanium plate blank at a temperature of 80°C for 3 hours, To obtain an acid-washed titanium plate, place the pickled titanium plate in 10% sodium bromide solution, carry out constant current anodic etching at a temperature of 0°C, and filter it after 5 minutes, and place it in a temperature of 80°C Dry for 2 hours unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com