A kind of nanometer diamond tool and its preparation method and application

A nano-diamond and diamond tool technology, applied in metal processing equipment, manufacturing tools, welding equipment and other directions, can solve the problems of difficult welding and difficult preparation of diamond tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

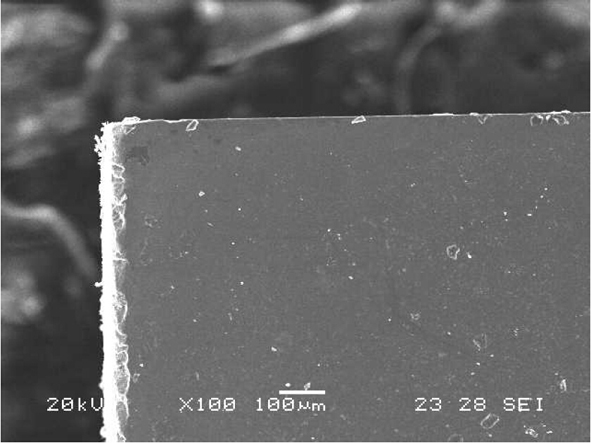

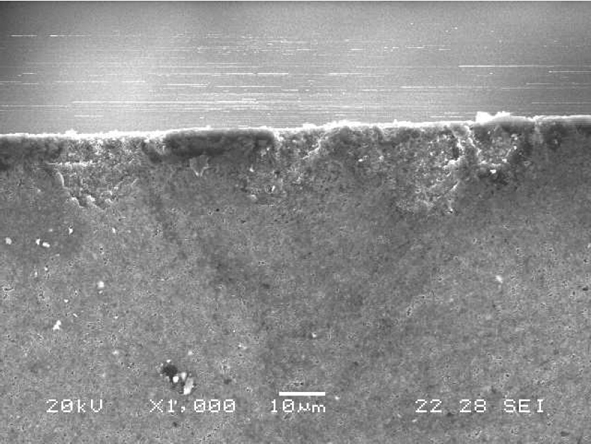

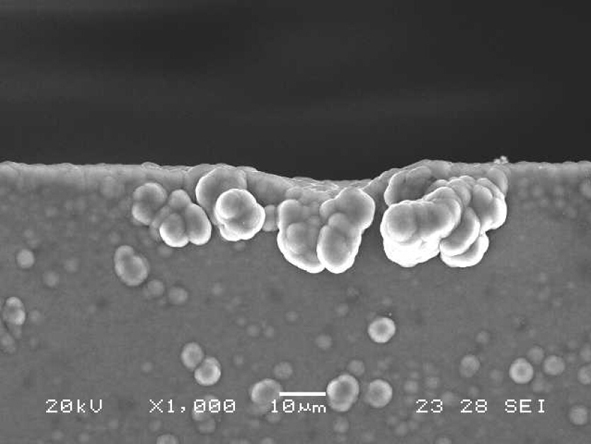

Image

Examples

Embodiment 1

[0069] This example provides a kind of preparation method of nano-diamond cutting tool, and it comprises the steps:

[0070] (1) Pretreatment process: 5mm square CVD single crystal diamond

[0071] Stress microscope inspection: check that there is more stress inside the diamond, and the stress is less;

[0072] X-ray transmission inspection: no cracks or holes inside the diamond;

[0073] Heat treatment: high-purity nitrogen (99.99%), 650°C, 10h;

[0074] Cold treatment: no;

[0075] Heat treatment: no;

[0076] (2) Cutting and shaping process: laser directional cutting (the power of the laser cutting is 500W, the wavelength is 192nm), and four 2.5mm square diamond single crystal substrates are obtained;

[0077] (3) Polishing process:

[0078] Matrix orientation: X-ray diffraction orientation;

[0079] Substrate fixation: take (100) crystal face grinding, use silver brazing, welding in argon protective atmosphere, welding temperature 450-600 ℃;

[0080] Substrate polis...

Embodiment 2

[0090] This example provides a kind of preparation method of nano-diamond cutting tool, and it comprises the steps:

[0091] (1) Pretreatment process: irregular high temperature and high pressure single crystal diamond with a diameter of 5 mm;

[0092] Stress microscope inspection: check that there are a large number of irregular stress layers inside the diamond, and the stress is relatively large;

[0093] X-ray transmission inspection: there are cracks on the surface and inside, and there are a large number of uneven nanometer to micrometer holes inside;

[0094] Heat treatment: high-purity nitrogen (99.99%), 650°C, 10h;

[0095] Cold treatment: liquid nitrogen (minus 196°C), treatment for 5 hours;

[0096] Hot pressing treatment: 130MPa, 180℃, 10h;

[0097] (2) Cutting and shaping process: laser directional cutting (the power of the laser cutting is 1kW, the wavelength is 512nm), 1 piece of 2.5mm irregular single crystal substrate, 3 pieces of 0.2-0.5mm irregular single ...

Embodiment 3

[0111] This example provides a kind of preparation method of nano-diamond cutting tool, and it comprises the steps:

[0112] (1) Pretreatment process: irregular natural single crystal diamond with a diameter of 5mm;

[0113] Stress microscope inspection: check that there are a large number of irregular stress layers inside the diamond, and the stress is relatively large;

[0114] X-ray transmission inspection: there are cracks on the surface and inside;

[0115] Heat treatment: high-purity nitrogen (99.99%), 650°C, 10h;

[0116] Cold treatment: no;

[0117] Hot pressing treatment: 130MPa, 180℃, 10h;

[0118] (2) Cutting and shaping process: laser directional cutting (the power of the laser cutting is 2kW, the wavelength is 1190nm), to obtain 2 pieces of 2.5mm irregular single crystal substrates, and 2 pieces of 0.2-0.5mm irregular single crystal substrates;

[0119] (3) Polishing process:

[0120] Matrix orientation: X-ray diffraction orientation;

[0121] Substrate fixa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com