Preparation method of large-area high-durability super-hydrophobic surface structure and product of preparation method

A super-hydrophobic surface and durability technology, which is applied in the process of producing decorative surface effects, microstructure technology, microstructure devices, etc. The problems such as the weak mechanical properties of the nanostructure can achieve the effect of improving the roughness and structural stability, low manufacturing cost and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

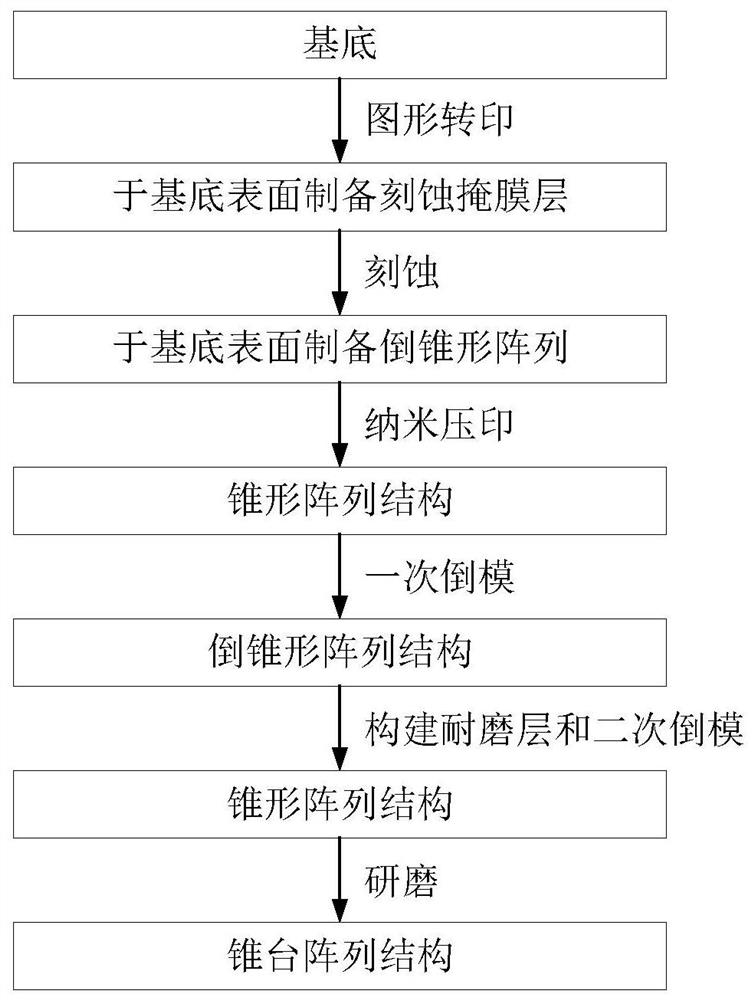

[0046] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a large-area and high-durability superhydrophobic surface structure. The preparation method includes the following steps:

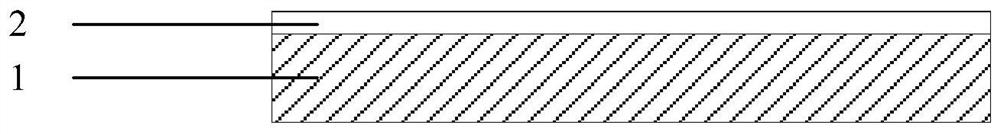

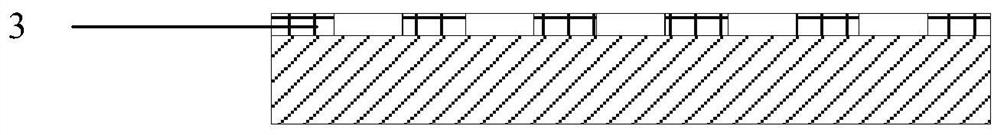

[0047] S1 as Figure 2-6 As shown, a preset pattern is prepared on the surface of the substrate 1 by photolithography, and then an etching mask layer 4 is prepared on the surface of the substrate with the preset pattern as an etching protection layer;

[0048] S2 as Figure 7 As shown, the substrate with the etching mask layer is etched, and the area without the etching mask layer is etched by wet etching. The etching solution is a strong alkali solution such as potassium hydroxide solution or hydrogen Sodium oxide solution, and then make inverted cone array 5 on this substrate;

[0049] S3 as Figure 8-12 As shown, the inverted hammer-shaped array prepared in step S2 is nano-imprinted with the imprint material 6 to obtain the tapered mask 7, and ...

Embodiment 2

[0075] Except the processing parameter in table 1, other specific operation steps and parameter are the same as embodiment 1.

[0076] Table 1 process parameters

[0077]

[0078]

Embodiment 3

[0080] Except the process parameter in table 2, other specific operation steps and parameter are the same as embodiment 1.

[0081] Table 2 process parameters

[0082] Silicon wafer thickness (μm) 750 Mask sputtering thickness (nm) RF mode Imprinting material polyester Molding material polyester Wear-resistant layer seed layer thickness (nm) 300 Wear-resistant layer thickness (μm) 100 Secondary molding material polyester Grinding thickness height ratio 1 / 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com