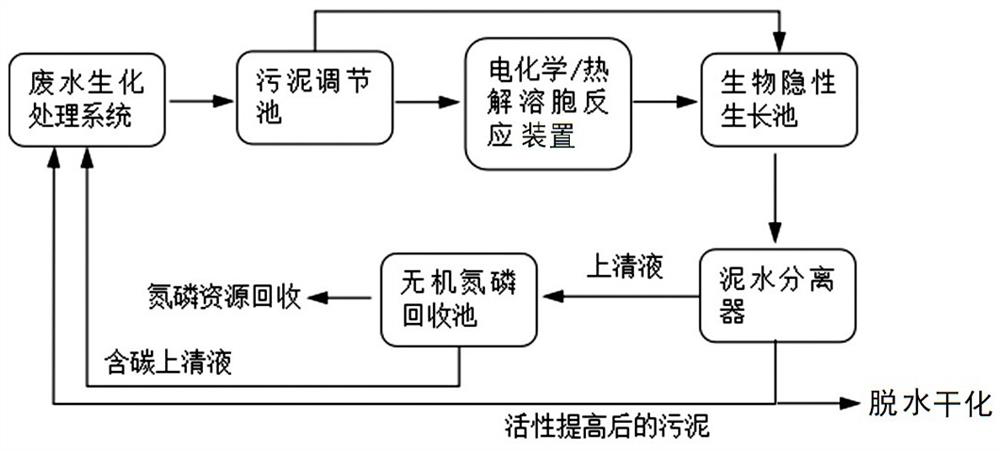

Treatment method and special equipment for sludge reduction, resource utilization and activity improvement

A treatment equipment and treatment method technology, applied in the direction of sludge treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problems of poor operation effect and unsatisfactory comprehensive treatment effect, so as to alleviate the lysis effect and overcome negative effects effect, lysis effect, continuous and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

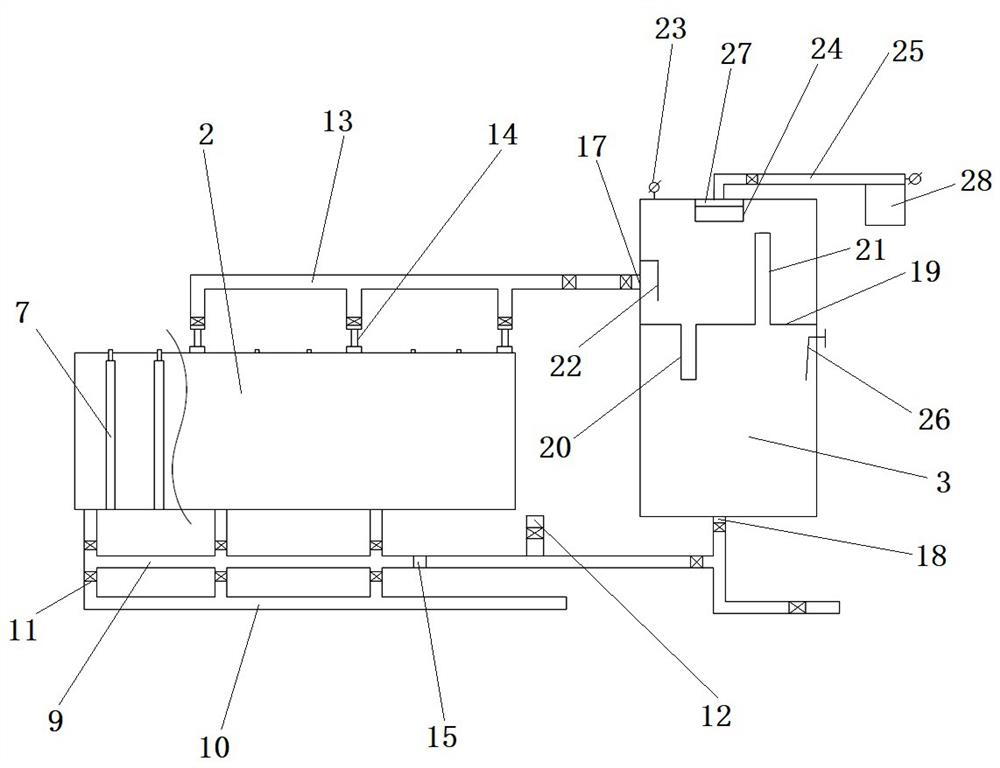

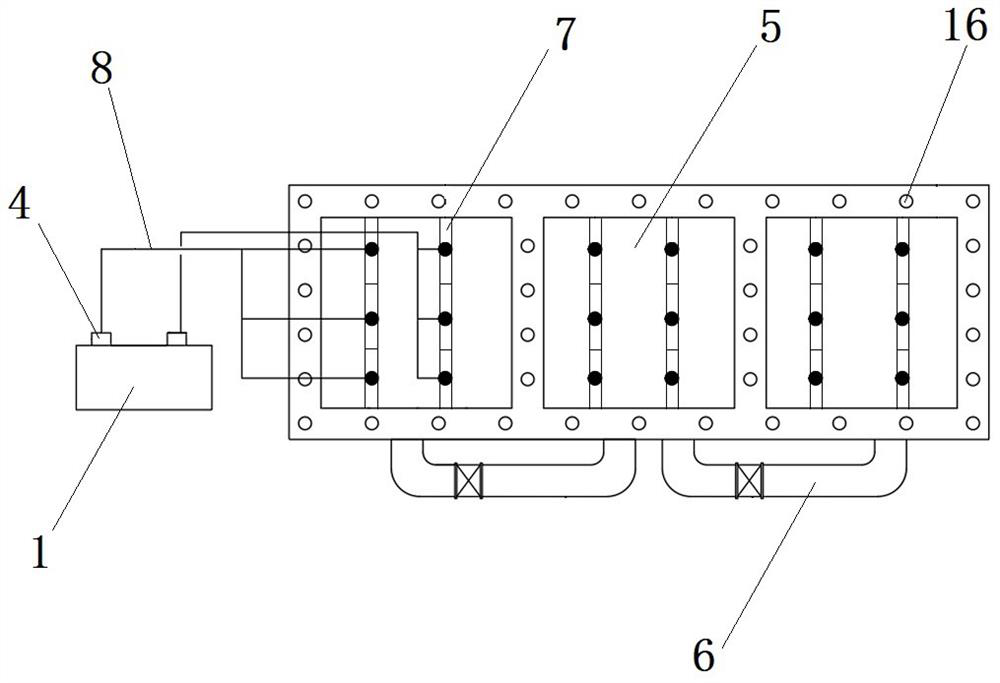

[0059] The treatment equipment of the present invention is connected with the biochemical inversion A / A / O system (hereinafter referred to as the simulated biochemical treatment system) of the simulated urban sewage treatment plant in stable operation. The simulated biochemical treatment system includes anoxic pool, anaerobic pool, aerobic pool, In the secondary sedimentation tank, denitrification is achieved through the process of nitrification in the aerobic tank - denitrification in the anoxic tank (the aerobic tank is returned to the anoxic tank at a ratio of 300%), and phosphorus removal is realized through the process of releasing phosphorus in the anaerobic tank - phosphorus accumulation in the aerobic tank , organic pollutants are removed in the anoxic tank, anaerobic tank, and aerobic tank, and the activated sludge mixture in the aerobic tank is separated from the mud and water in the secondary settling tank. Part of the sludge is returned to the front of the simulation ...

Embodiment 2

[0064] The treatment equipment of the present invention is connected with a biochemical inversion A / A / O system of a simulated urban sewage treatment plant in stable operation, and the structure and operation of the simulated biochemical treatment system are the same as in Embodiment 1.

[0065] The excess sludge of the simulated biochemical treatment system is sent into the sludge regulating tank of the equipment of the present invention, and the sludge concentration is adjusted to stabilize to 14000mg / L (in SS) in the sludge regulating tank, and then pumped into the electrochemical / pyrolysis solution Cell reaction device, adjust the amount of sludge circulation to make the sludge treatment time reach 6h, when the DC output voltage of the electrochemical / pyrolysis cell reaction device is 90V, and the current output is 6A, the pyrolysis temperature of the reactor is stable at 55°C, Under this working condition, the treated sludge concentration is reduced to 7000mg / L (calculated ...

Embodiment 3

[0069] The treatment equipment of the present invention is connected with a biochemical inversion A / A / O system of a simulated urban sewage treatment plant in stable operation, and the structure and operation of the simulated biochemical treatment system are the same as in Embodiment 1.

[0070] Send the excess sludge of the simulated biochemical treatment system into the sludge regulating tank of the equipment of the present invention, adjust the sludge concentration in the sludge regulating tank to stabilize to 6000mg / L (in SS), and then pump it into the electrochemical / pyrolysis solution Cell reaction device, adjust the amount of sludge circulation to make the sludge treatment time reach 2h, when the DC output voltage of the electrochemical / pyrolysis cell reaction device is 40V, and the current output is 4A, the pyrolysis temperature of the reactor is stable at 45°C. Under this working condition, the sludge concentration after treatment is reduced to 3100mg / L (calculated as S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com