Perylene anhydride type polyarylene sulfide with tree structure, and preparation method and application thereof

A technology of polyarylene sulfide and tree structure, which is applied in the field of polymer synthesis and can solve problems such as limited performance, difficulty in tracking marks, lack of photoelectric and magnetoelectric properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Preparation process of the present invention can represent its process with following example reaction:

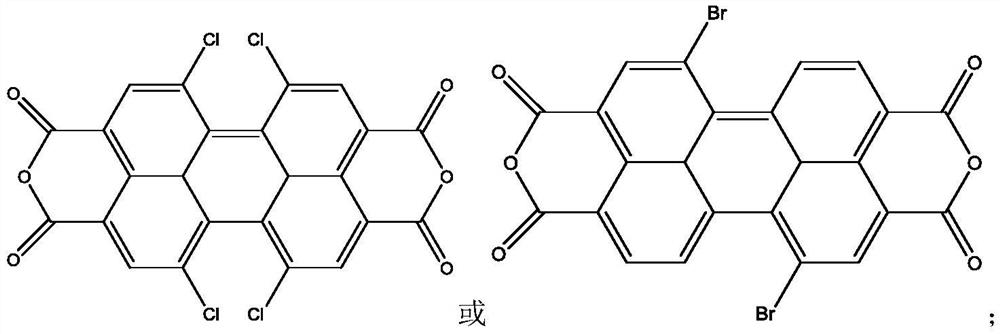

[0050] Step 1): Substituted perylene anhydride reacts with polycarboxylic acid under the action of polar solvent:

[0051]

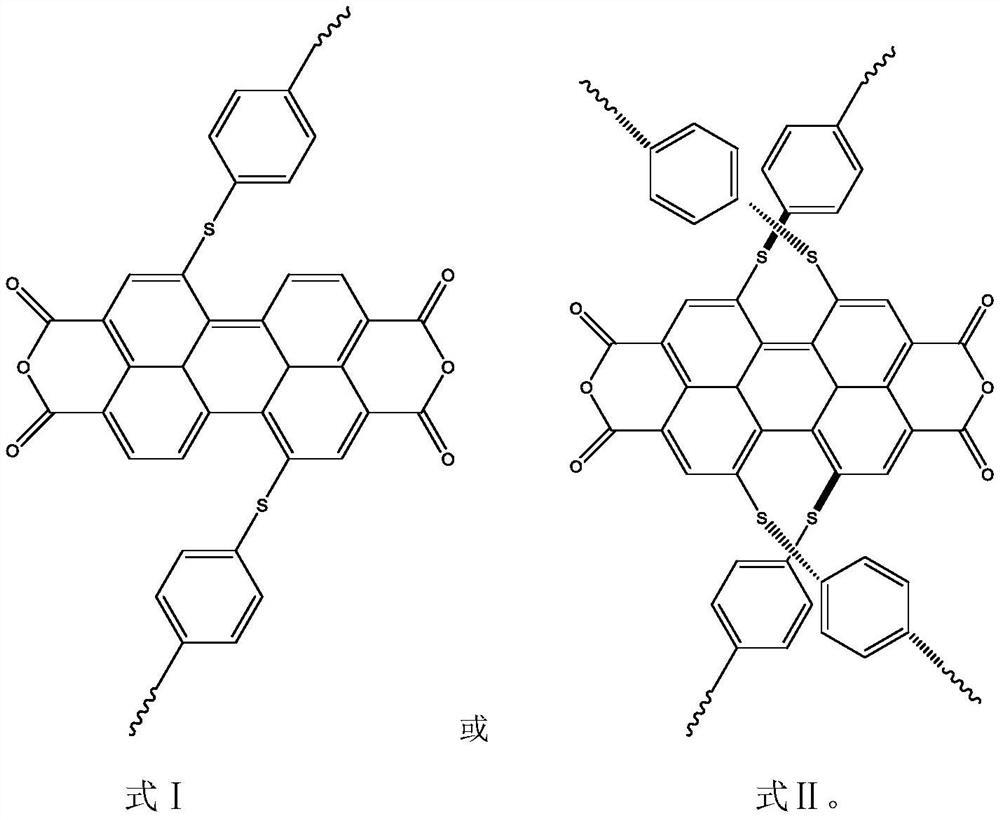

[0052] Step 2): The perylene anhydride complex reacts with the dihalogen aromatic compound and sulfur further under the action of an aprotic polar solvent to form a perylene anhydride polyarylene sulfide with a dendritic structure:

[0053]

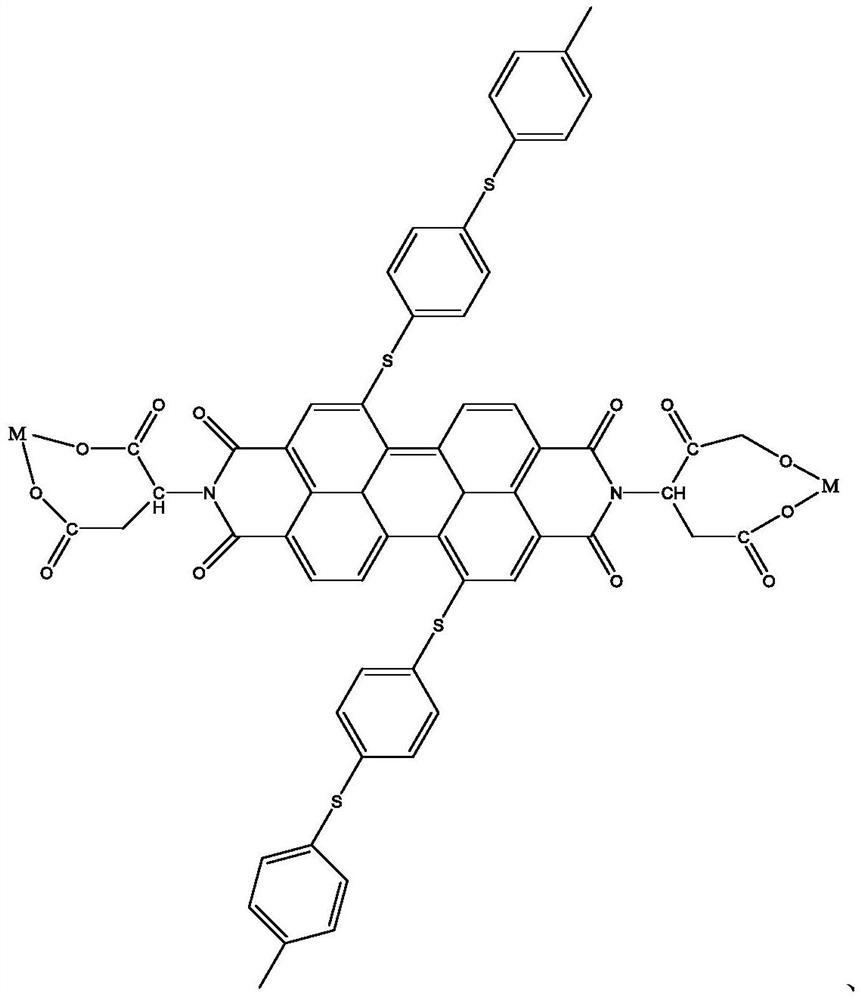

[0054] Step 3): The perylene anhydride type polyarylene sulfide with carboxyl group-containing tree structure further reacts with magnetic and optical metal elements under the action of a solvent to form a dendritic structure of perylene anhydride type magneto-optical effect multifunctional polyarylene sulfide:

[0055]

[0056]

[0057] The general structure of the novel perylene anhydride type magneto-optical effect multifunctional polyarylene sulfide structure with dendritic structure obtai...

Embodiment 1

[0068] Add 2500ml of anhydrous NMP into a 5L reactor, add 76.85g (0.4mol) of citric acid and 55.01g (0.1mol) of 1,7 dibromoperylene anhydride under nitrogen protection, stir for 2 hours, heat up to 120°C and keep 2 hours; then add 260g sodium sulfide (three crystal waters), slowly heat up to 200°C to remove moisture, then cool down to 160°C; then add 279.3g (1.9mol) 1,4-dichlorobenzene, nitrogen protection Next, close the reactor, gradually heat up to 225°C, after two hours of reaction, heat up to 250°C to continue the reaction for 4 hours, then cool down to below 100°C, then add terbium nitrate pentahydrate 174g (0.4mol), and react at 120°C for 2 Hours. The reactor was opened, the product was washed 6 times with deionized water at 80° C., and dried at 100° C. for 12 hours to obtain 328 g of powder product. The product has a melting point of 295°C, a glass transition temperature of 130°C, an intrinsic viscosity of 0.31 (the intrinsic viscosity test condition is 206°C, and α-c...

Embodiment 2

[0070] Add 2500ml anhydrous NMP in the reactor of 5L, add 58.85g glutamic acid, 53.01g tetrachloroperylene anhydride under nitrogen protection, stir 2 hours, be warming up to 120 ℃ and keep 2 hours; Then add 234g sodium sulfide ( three crystal waters), slowly raise the temperature to 200°C to remove moisture, then cool down to 160°C; then add 264.6g of 1,4-dichlorobenzene, under the protection of nitrogen, close the reactor, gradually raise the temperature to 225°C, and react for two hours Afterwards, the temperature was raised to 250° C. to continue the reaction for 4 hours, and then the temperature was lowered to below 100° C., then 90.2 g of gadolinium nitrate hexahydrate was added, and the reaction was carried out at 120° C. for 2 hours. The reactor was opened, the product was washed 6 times with deionized water at 80° C., and dried at 100° C. for 12 hours to obtain 282 g of powder product. The product has a melting point of 295°C, a glass transition temperature of 110°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com