Multifunctional nanozyme and its preparation method and application

A multi-functional, nano-enzyme technology, applied in chemical instruments and methods, catalyst activation/preparation, lanthanide oxides/hydroxides, etc., can solve the problems of expensive equipment, long measurement time, and easy inactivation of chromatography , to achieve the effect of overcoming easy inactivation, simple preparation method and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The second technical problem to be solved by this invention is to provide the preparation method of above-mentioned multifunctional nanozyme, a kind of method that is easy to synthesize, and this method comprises the following steps:

[0029] The first step is to prepare CeO 2 : Mix a certain amount of cerium nitrate aqueous solution with the ethylene glycol solution of polyvinylpyrrolidone, under vigorous stirring, add excess sodium hydroxide solution to form a precipitate, then add appropriate amount of hydrogen peroxide solution, stir for 1 hour and then transfer to high temperature reaction kettle React at 120-350°C for 2-3 hours, cool to room temperature, collect the precipitate by centrifugation, wash the precipitate with ethanol for 3 times, and dry at 60-80°C to obtain CeO 2 .

[0030] The second step is to prepare multifunctional nanozymes: add CeO to a certain volume of aqueous solution containing terbium nitrate and copper nitrate 2 Ethanol solution, stir e...

Embodiment 1

[0035] Example 1 Multifunctional nanozyme CeO 2 Preparation of @CuTb

[0036] CeO 2 Preparation: 0.1 g Ce(NO 3 ) 3 ·6H 2 The cerium nitrate solution produced by dissolving O in 1 mL of water was mixed with the PVP ethylene glycol solution produced by dissolving 0.04 g of polyvinylpyrrolidone (PVP, molecular weight 40,000) in 6 mL of ethylene glycol, and 2 mL of 1 mM NaOH solution, add 1 mL of 30% H 2 o 2 The solution was stirred for 1 hour, then transferred to a high-temperature reactor for 2 hours at 160°C, cooled to room temperature (25°C), centrifuged to collect the precipitate, washed with ethanol for 3 times, and dried in an oven at 80°C for later use.

[0037] CeO 2 @CuTb preparation: To 5 mL DMF (N,N' dimethylformamide), sequentially add 1 mL 30 mM Tb (NO 3 ) 3 and 1 mL of 30 mM Cu (NO 3 ) 2 aqueous solution, and then add 2 mL containing 0.05 g CeO prepared above 2 Mixed solution 1 was generated by stirring evenly, and 1 mL of DMF solution containing 30 mM ...

Embodiment 2

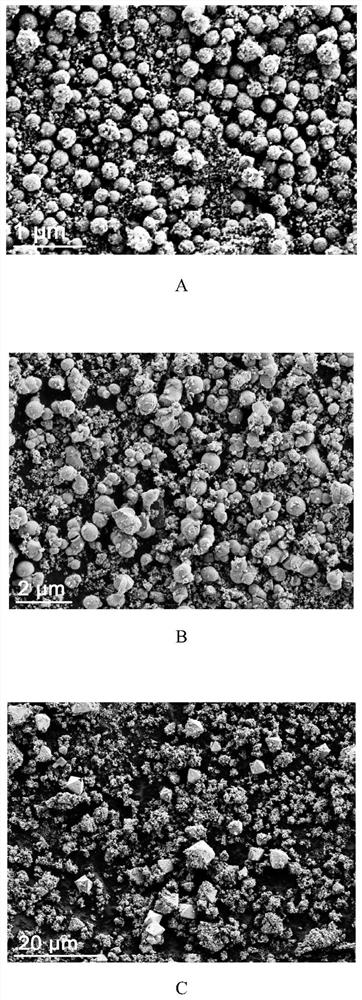

[0038] Example 2 Multifunctional nanozyme CeO 2 Preparation of @CuTb

[0039] To 4 mL DMF, sequentially add 1 mL containing 30 mM Tb (NO 3 ) 3 and 1 mL containing 30 mM Cu (NO 3 ) 2 , then add 2 mL containing 0.05 g CeO prepared above 2 Mixed solution 1 was generated by stirring evenly, and 2 mL of DMF solution containing 30 mM dipicolinic acid was added to the mixed solution 1 to form terbium ion: copper ion: dipicolinic acid: CeO 2 The molar ratio of the mixed solution is 1:1:2:10. After continuous stirring for 10 minutes, the mixed solution is transferred to a high-temperature reactor, reacted at 140°C for 24 hours, cooled to room temperature, and centrifuged to collect the precipitate. After washing with pure water for 3 times, put it in a drying oven at 60°C and dry it for later use. figure 1 B is the prepared multifunctional nanozyme CeO 2 SEM images of @CuTb, the multifunctional nanozyme CeO 2 @CuTb is a spherical particle with an average particle size of 1.2 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com