Preparation method and application of iron-zinc vanadate ion battery positive electrode material

A technology for zinc-ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as poor cycle stability of zinc-ion batteries, and achieve excellent zinc-ion battery performance, high rate performance, and uniform size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Take 4mlH 2 o 2 Add to 40ml deionized water, weigh 2mmol of V 2 o 5 (0.364g) was added to the above solution, stirred in a water bath (300rpm) at 40°C until dissolved, and then weighed 0.2mmol of Fe(NO 3 ) 3 9H 2 Add O (0.0808g) to it, add 0.5g PVP after stirring for five minutes, and continue magnetic stirring for 30 minutes;

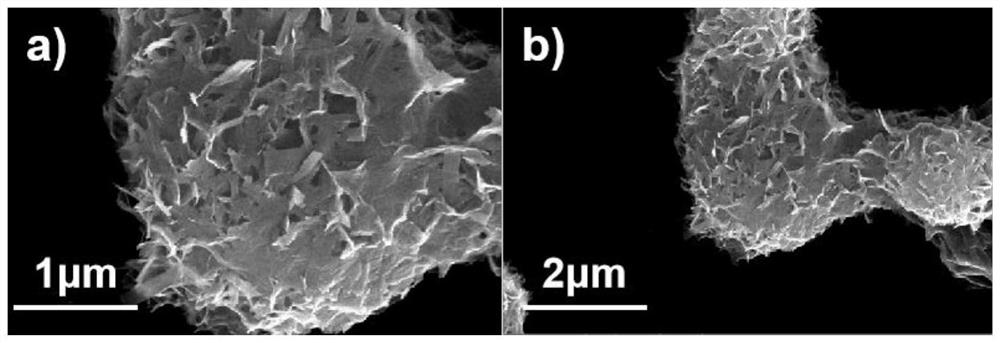

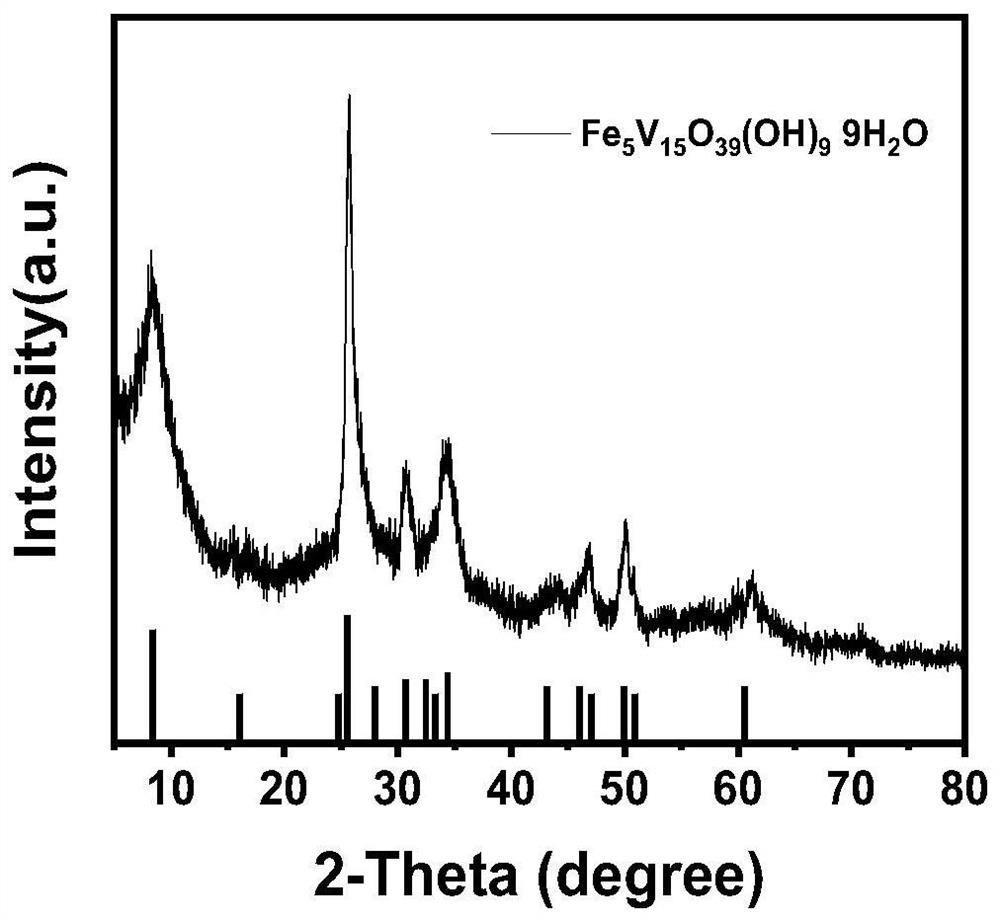

[0030] (2) Transfer the above mixed solution to a 50ml reaction kettle, and react at 180°C for 12h. After the reaction, the product was taken out and centrifuged and washed three times. The washing solvent was deionized water. The washed product was placed in a vacuum oven at 60°C for 12 hours to obtain the iron vanadate material; the SEM images of the iron vanadate material at different magnifications are as follows figure 1 Shown; The XRD pattern of this ferric vanadate material is as figure 2 show; combine figure 1 (a-b) It can be seen that the particle size of the iron vanadate material is 2 μm, which is determined by figure ...

Embodiment 2

[0035] (1) Take 1mlH 2 o 2 Add to 40ml deionized water, weigh 0.4mmol of NH 4 VO 3 Add to the above solution, stir in a water bath (300rpm) at 40°C until dissolved, then weigh 0.04mmol of FeCl 3 Add it, add 0.04g PVP after stirring for five minutes, and continue magnetic stirring for 30 minutes;

[0036] (2) Transfer the above mixed solution to a 50ml reactor and react at 100°C for 10h. After the reaction, the product was taken out and centrifuged and washed three times. The washing solvent was deionized water, and the washed product was placed in a vacuum oven at 60°C for 12 hours to obtain an iron vanadate material;

[0037] (3) Use the above-mentioned ferric vanadate material as the active material of the positive electrode material of zinc ion battery, grind it with carbon black and PVDF at a ratio of 8:1:1, add NMP as a solvent, grind it for 30 minutes, and use a scraper to scrape it on the Ti foil. Dry in a vacuum oven at 60°C;

Embodiment 3

[0041] (1) Take 10mlH 2 o 2 Add to 40ml deionized water, weigh 4mmol of NH 4 VO 3 Add to the above solution, stir in a water bath (300rpm) at 40°C until dissolved, then weigh 0.4mmol of FeCl 3 Add it, add 0.6g DTAB after stirring for five minutes, and continue magnetic stirring for 30 minutes;

[0042](2) Transfer the above mixed solution to a 50ml reactor and react at 200°C for 30h. After the reaction, the product was taken out and centrifuged and washed three times. The washing solvent was deionized water, and the washed product was placed in a vacuum oven at 60°C for 12 hours to obtain an iron vanadate material;

[0043] (3) Use the above-mentioned ferric vanadate material as the active material of the positive electrode material of zinc ion battery, grind it with carbon black and PVDF at a ratio of 8:1:1, add NMP as a solvent, grind it for 30 minutes, and use a scraper to scrape it on the Ti foil. Dry in a vacuum oven at 60°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com