Method for improving triboelectric output performance of protein film by changing protein structure

A technology of protein structure and output performance, applied in triboelectric generators and other directions, can solve the problems of discarding vegetable protein, harsh extraction conditions, cumbersome processing steps, etc., and achieve the effect of improving the solution degree, avoiding strong alkaline conditions and improving output performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the control group, the plant protein film was prepared, and the plant protein film was prepared by the deposition method: first, the film-forming liquid was prepared, and the insoluble protein powder was dissolved in an appropriate solvent: water or ethanol aqueous solution, and then an appropriate amount of glycerin was added as a plasticizer. After heat treatment, the protein is denatured to obtain a more extended structure required for film formation, and finally the solvent is evaporated to obtain a protein film with uniform texture, certain transparency and good flexibility.

[0033] The experimental group prepared the plant protein film by using the deposition method to prepare the plant protein film: firstly, the film-forming liquid was prepared, and the insoluble protein powder and a small amount of another protein were co-dissolved in a strong alkali aqueous solution (1-5% , w / w), after being kept under this condition for a short period of time, acidified to ...

example 1

[0038]The first is the preparation of the experimental histone solution, disperse 1.25g of insoluble rice glutenin in 25mL aqueous solution (5%, w / w), and add 0.0125g of another variety of rice glutenin, by adding 1M hydrogen Sodium oxide was adjusted to pH 12 to fully dissolve it under strong alkalinity. After stirring for 3 hours, 1M hydrochloric acid was added to acidify the solution to pH 10.5, and then 0.1M hydrochloric acid was used to adjust the solution to pH 7.5. The entire pH cycle process needs to be carried out under stirring conditions. Finally, the salt and other small molecular compounds in the protein solution were removed by dialysis to obtain the film-forming solution of the experimental group.

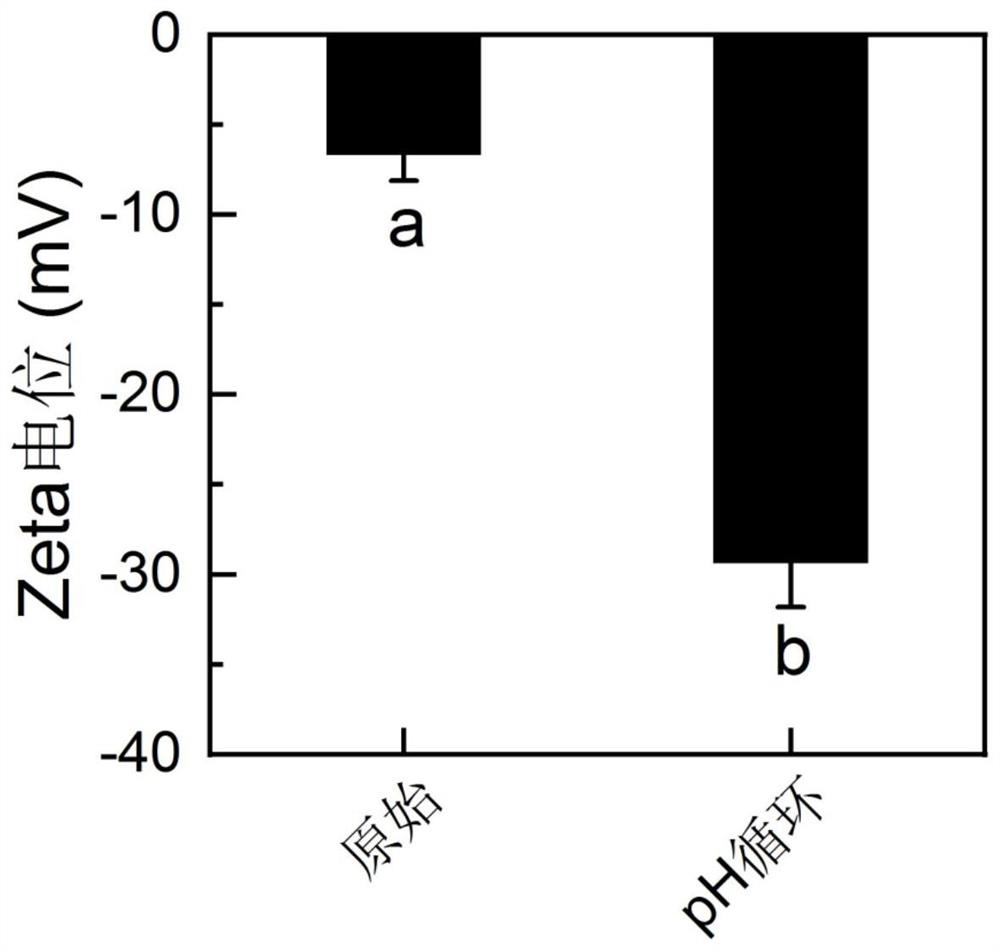

[0039] Such as figure 1 As shown, compared with the negative control group (without any treatment of rice gluten fully hydrated in water), the absolute value of the protein solution potential of the experimental group is higher, indicating that the protein solution ...

example 2

[0041] The first is the preparation of the experimental histone solution, disperse 1.25g of insoluble rice glutenin in 25mL aqueous solution (5%, w / w), and add 0.0125g of another variety of rice glutenin, by adding 1M hydrogen Sodium oxide was adjusted to pH 12 to fully dissolve it under strong alkalinity. After stirring for 3 hours, 1M hydrochloric acid was added to acidify the solution to pH 10.5, and then 0.1M hydrochloric acid was used to adjust the solution to pH 7.5. The entire pH cycle process needs to be carried out under stirring conditions. Finally, the salt and other small molecular compounds in the protein solution were removed by dialysis to obtain the film-forming solution of the experimental group.

[0042] Next is the preparation of the protein solution of the control group, dispersing 1.25g of insoluble rice gluten in 25mL aqueous solution (5%, w / w), adjusting the pH to 12 by adding 1M sodium hydroxide, making it under strong alkaline Fully dissolved and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com