Bi-component organic silicon pouring sealant and preparation method thereof

A silicone potting, two-component technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of restricted product lines, long curing time, low production efficiency, etc. The effect of production efficiency, good fluidity, and ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

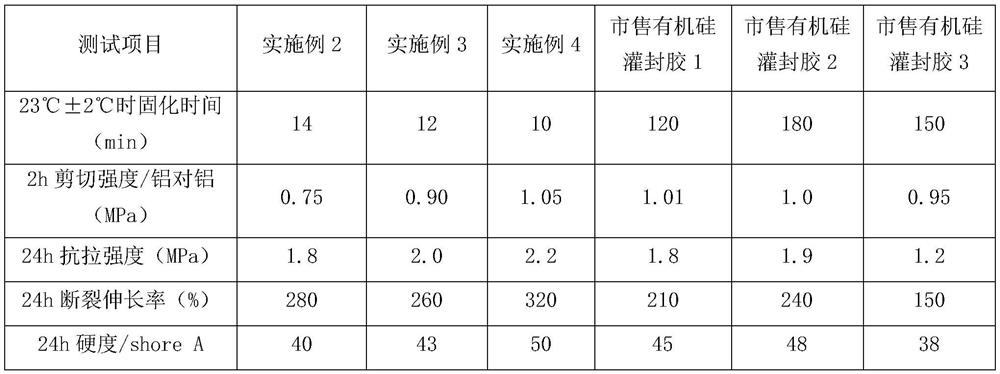

Examples

Embodiment 1

[0032] This example provides a two-component silicone encapsulant whose raw materials include component A and component B,

[0033] Component A is composed of 30-40 parts by weight of vinyl polydimethylsiloxane, 10-40 parts by weight of filler and 0.1-4 parts by weight of curing accelerator;

[0034] Component B consists of 0-25 parts by weight of hydrogen-containing silicone oil, 10-40 parts by weight of filler, 0.1-0.4 parts by weight of alkynyl cyclohexanol, 0.1-0.4 parts by weight of high-activity platinum complex, and 1-12 parts by weight of even Joint composition;

[0035] Among them, the mass ratio of component A to component B is 1:1, the hydrogen-containing silicone oil is a methyl-terminal hydrogen-containing silicone oil with a hydrogen content of 0.25% to 0.38%, and the platinum content in the highly active platinum complex is 11130ppm~ 20200ppm.

[0036] In this embodiment, the raw materials of the two-component silicone encapsulant include component A and compo...

Embodiment 2

[0049] This example provides a specific implementation. The raw materials of a two-component silicone encapsulant include component A and component B, wherein component A consists of 30 parts by weight of vinyl polydimethylsiloxane, 20 parts by weight It consists of 20 parts by weight of filler and 1 part by weight of curing accelerator. Component B consists of 20 parts by weight of methyl-terminal hydrogen-containing silicone oil with a hydrogen content of 0.25% to 0.38%, 20 parts by weight of filler, 0.1 part by weight of alkynyl cyclohexanol, It is composed of 0.2 parts by weight of highly active platinum complex with a platinum content of 11130 ppm to 20200 ppm and 4 parts by weight of a coupling agent.

[0050] When preparing, firstly pre-treat the fillers required for components A and B, that is, dry them; then prepare components A and B respectively, and then mix components A and B by 1: The mass ratio of 1 can be quickly obtained by mixing the silicone potting compound...

Embodiment 3

[0052] This example provides a specific implementation. The raw materials of a two-component silicone potting adhesive include component A and component B, wherein component A consists of 35 parts by weight of vinyl polydimethylsiloxane, 25 parts by weight Parts by weight of filler and 1 part by weight of curing accelerator, component B consists of 20 parts by weight of methyl-terminal hydrogen-containing silicone oil with a hydrogen content of 0.25% to 0.38%, 25 parts by weight of filler, 0.2 part by weight of alkynyl cyclohexanol, It is composed of 0.3 parts by weight of highly active platinum complex with a platinum content of 11130 ppm to 20200 ppm and 8 parts by weight of a coupling agent.

[0053] When preparing, firstly pre-treat the fillers required for components A and B, that is, dry them; then prepare components A and B respectively, and then mix components A and B by 1: The mass ratio of 1 can be quickly obtained by mixing the silicone potting compound evenly, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com