Method for comprehensively recovering bismuth, silver and copper metal by taking bullion lead as raw material

A technology of copper metal and lead-bismuth alloy, applied in the direction of non-metal elements, chemical instruments and methods, selenium/tellurium compounds, etc., can solve the problems of high environmental pressure, long process and complicated process, so as to improve the recovery cycle and shorten the recovery The effect of shortening the cycle and shortening the smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

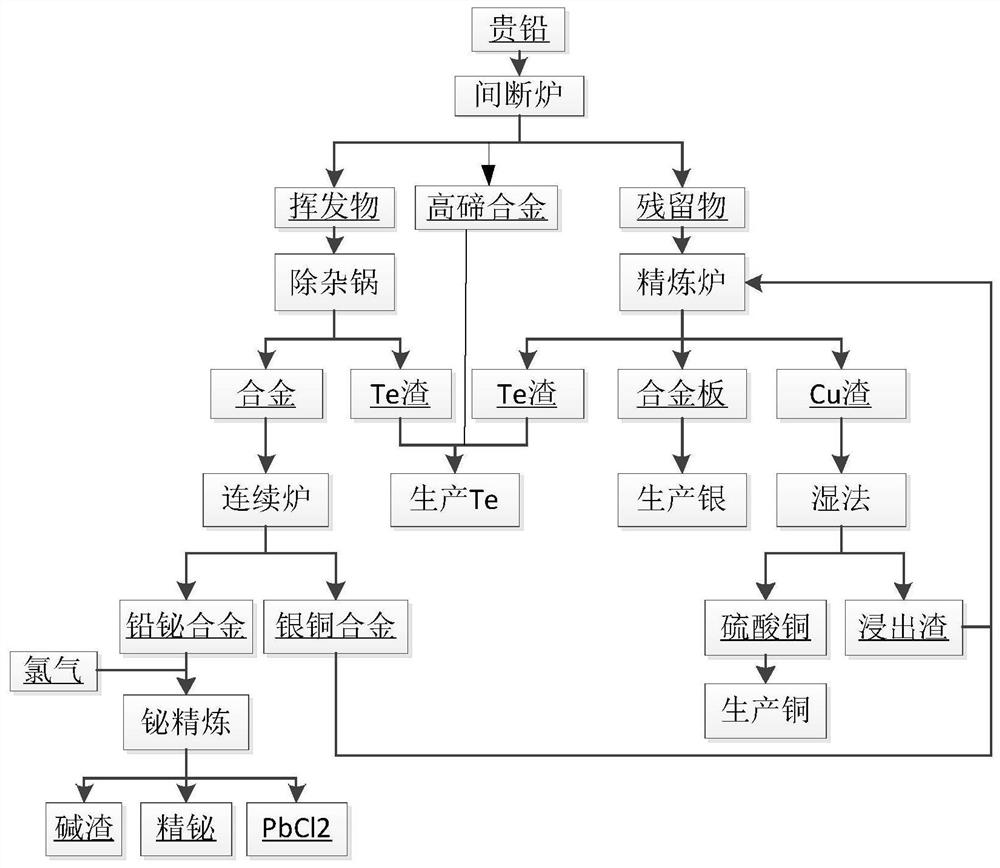

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: described noble lead composition comprises following mass percent: Ag10~65%, Cu8~20%, Bi20~60%, Te4~8%, Pb<10%, Sb<10%; Copper-silver alloy 1: Ag45 ~85%, Cu10~40%, Bi<5%, Te3~10%, Pb<5%, Sb<10%; copper-silver alloy II: Ag45~85%, Cu4~20%, Bi<10%, Te <1%, Pb<10%, Sb<5%; lead-bismuth alloy Ⅰ: Bi50-90%, Te1-8%, Ag0.5-5%, Cu0.1-1%; lead-bismuth alloy Ⅱ: Bi50- 90%, Te<0.3%, Ag0.5~5%, Cu0.5~1%; lead-bismuth alloy III: Bi50-90%, Ag<20g / t, Cu<10g / t. The process is as follows:

[0025] Step 1: First place the precious lead in a discontinuous vacuum furnace, vacuum separate lead, bismuth, gold, silver and copper under the conditions of controlling the vacuum degree of 10-100Pa, the temperature of 1000-1300℃, and the distillation time of 7-9 hours , tellurium, through zonal condensation, the volatile lead-bismuth alloy I and high-tellurium alloy I are produced; the residue copper-silver alloy I;

[0026] Step 2: Put the lead-bismuth alloy I obtained in step 1 in a ...

Embodiment 2

[0033] Embodiment 2: steps and process are identical with embodiment 1, no longer repeat;

[0034] Composition (%) Ag Cu Bi Te Pb Sb precious lead 14.5 11.20 61.50 4.60 5.56 2.50 Copper Silver Alloy I 54.51 30.60 2.00 3.5 0.68 4.80 Copper Silver Alloy II 56.5 8.50 7.55 0.4 3.0 2.10 Lead Bismuth Alloy Ⅰ 2.00 0.3 83.80 4.8 6.90 Lead Bismuth Alloy II 2.50 0.50 85.50 0.05 Lead Bismuth Alloy III <20g / t

Embodiment 3

[0035] Embodiment 3: steps and process are identical with embodiment 1, no longer repeat;

[0036] Composition (%) Ag Cu Bi Te Pb Sb precious lead 63.00 8.20 20.5 4.00 1.10 1.9 Copper Silver Alloy I 78.65 10.20 1.00 3.6 0.02 0.56 Copper Silver Alloy II Lead Bismuth Alloy Ⅰ 2.00 0.2 82.80 2.76 1.33 Lead Bismuth Alloy II 2.8 0.5 83.55 0.1 Lead Bismuth Alloy III <20g / t

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com