Manufacturing method and structure of miniaturized three-dimensional inductor with magnetic core

A manufacturing method and inductance technology, which can be used in magnetic core manufacturing, inductance/transformer/magnet manufacturing, transformer/inductor magnetic core, etc., can solve the problems of increasing magnetic core eddy current loss, restricting industrialization development, and restricting inductance performance, etc. Achieve the effect of small scattered magnetic flux, increase inductance capacity and performance optimization space, and high magnetic induction intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below through specific embodiments.

[0039] refer to Figure 1 to Figure 13 , a method for manufacturing a miniaturized three-dimensional inductor with a magnetic core, comprising the steps of:

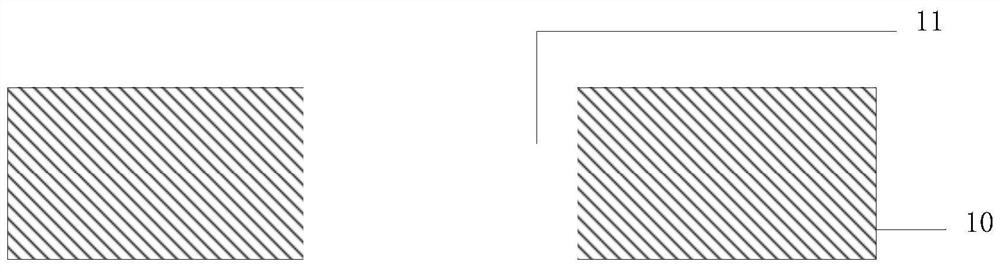

[0040] 1) Fabricate at least one microgroove structure 11 on the magnetic substrate 10 . The magnetic substrate is sheet-shaped, has a front side and a back side, is made of magnetic material, is square or circular in shape, and has a thickness of 0.05-3mm.

[0041] The manufacturing process of the micro-groove structure 11 may be laser etching, plasma bombardment, sandblasting or ultrasonic etching, etc., and the side length of the micro-groove structure 11, that is, the width or length, is 0.05-3 mm. The number and shape of the micro-groove structures 11 are not limited. In the magnetic substrate, the magnetic core is formed outside the micro-groove structure, that is, the magnetic core surrounds the micro-groove junction. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com