Method for preparing olivine type five-element high-entropy lithium battery precursor by recycling lithium battery

A technology of olivine type and precursor, which is applied in the direction of battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of difficult metal recycling, fast capacity decay, and low material capacity, and achieves simplified recycling process, recycling Effects of cost reduction, thermal stability performance and cycle performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

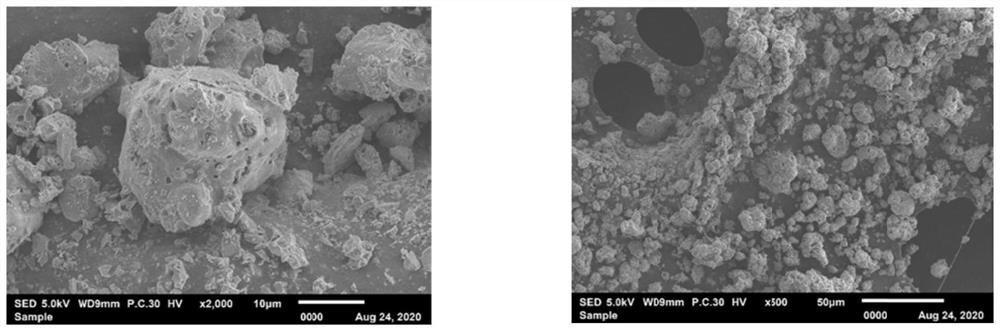

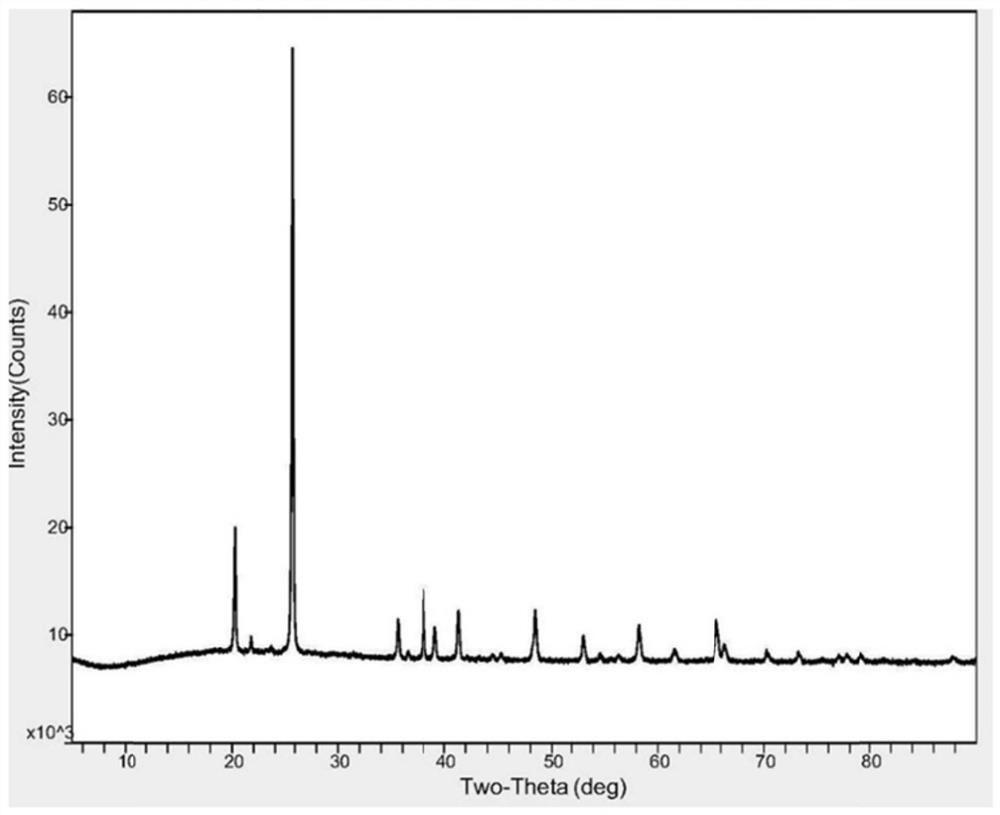

Image

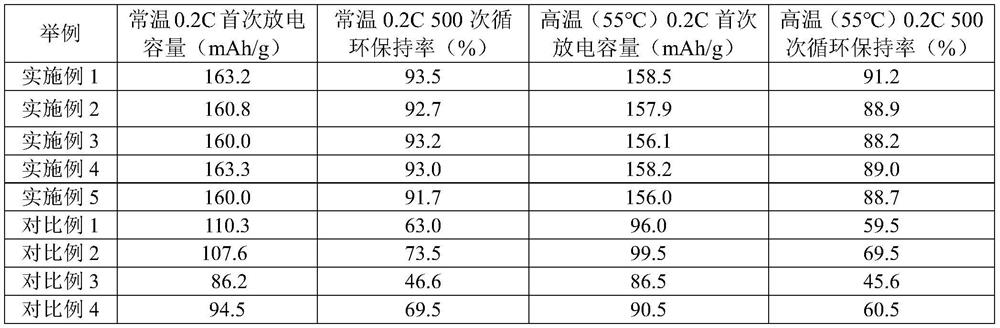

Examples

Embodiment 1

[0036] (1) Take 100g of retired nickel-cobalt-manganese ternary and 200g of retired iron-lithium cathode sheets respectively and carry out a calcination experiment at 450 °C for 3 h to obtain cathode materials that remove organic matter and carbon;

[0037] (2) adding the positive electrode sheet obtained in the step (1) into a sulfuric acid solution with a sulfuric acid concentration of 0.5 mol / L, the volume of the dilute sulfuric acid solution is 2 L, and the uniform air flow rate is 0.20 m 3 / h, the temperature of the reaction solution is 70°C, and the reaction time is 6h;

[0038] (3) after filtering and washing the filter residue obtained in the step (2), add 1.5 L of phosphoric acid solution with a phosphoric acid concentration of 30 g / L, add 60 g of 30% hydrogen peroxide, and the reaction temperature is 50 ° C. After the reaction for 5 h, five kinds of liquids in the solution were adjusted. ion concentration such that c(Fe 3+ ): c(Al 3+ ):c(Ni 2+ ):c(Co 2+ ):c(Mn 2...

Embodiment 2

[0041] (1) 60g decommissioned nickel-cobalt-manganese ternary and 240g decommissioned iron-lithium cathode sheets were respectively taken for 1 h roasting experiment at 700 °C to obtain cathode materials with removal of organics and carbon;

[0042] (2) adding the positive electrode sheet obtained in the step (1) into the acetic acid solution with a hydrochloric acid concentration of 4.0 mol / L, the volume of the dilute acetic acid solution is 0.6 L, and the uniform air flow rate is 0.10 m 3 / h, the temperature of the reaction solution is 150°C, and the reaction time is 4h;

[0043] (3) after filtering and washing the filter residue obtained in the step (2), add 2.0 L of phosphoric acid solution with a phosphoric acid concentration of 60 g / L, add 150 g of 30% hydrogen peroxide, and the reaction temperature is 90 ° C. After the reaction for 3 h, five kinds of liquids in the solution were adjusted. ion concentration such that c(Fe 3+ ): c(Al 3+ ):c(Ni 2+ ):c(Co 2+ ):c(Mn 2+ ...

Embodiment 3

[0046] (1) Take 75g of decommissioned nickel-cobalt-manganese ternary and 225g of decommissioned iron-lithium cathode sheets respectively and carry out a roasting experiment at 600 °C for 2 hours, to obtain cathode materials with removal of organics and carbon;

[0047] (2) adding the positive electrode sheet obtained in the step (1) into the hypochlorous acid solution with a hypochlorous acid concentration of 4.0 mol / L, the volume of the diluted hypochlorous acid solution is 0.6 L, and the uniform air flow rate is 0.018 m 3 / h, the temperature of the reaction solution was 80°C, and the reaction time was 6h;

[0048] (3) after filtering and washing the filter residue obtained in step (2), adding 2.2 L of phosphoric acid solution with a phosphoric acid concentration of 40 g / L, adding 100 g of 30% hydrogen peroxide, the reaction temperature is 80 ° C, and adjusting five kinds of solutions in the solution after the reaction for 2 h ion concentration such that c(Fe 3+ ): c(Al 3+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com