Method for preparing rare earth ion doped optical fiber preform, device and product

A technology of doping optical fiber and rare earth ions, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increasing the complexity and process difficulty of OVD equipment, low deposition efficiency of phosphorus compounds, and longitudinal unevenness of preforms, etc. High utilization rate, uniform deposition and controllable deposition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

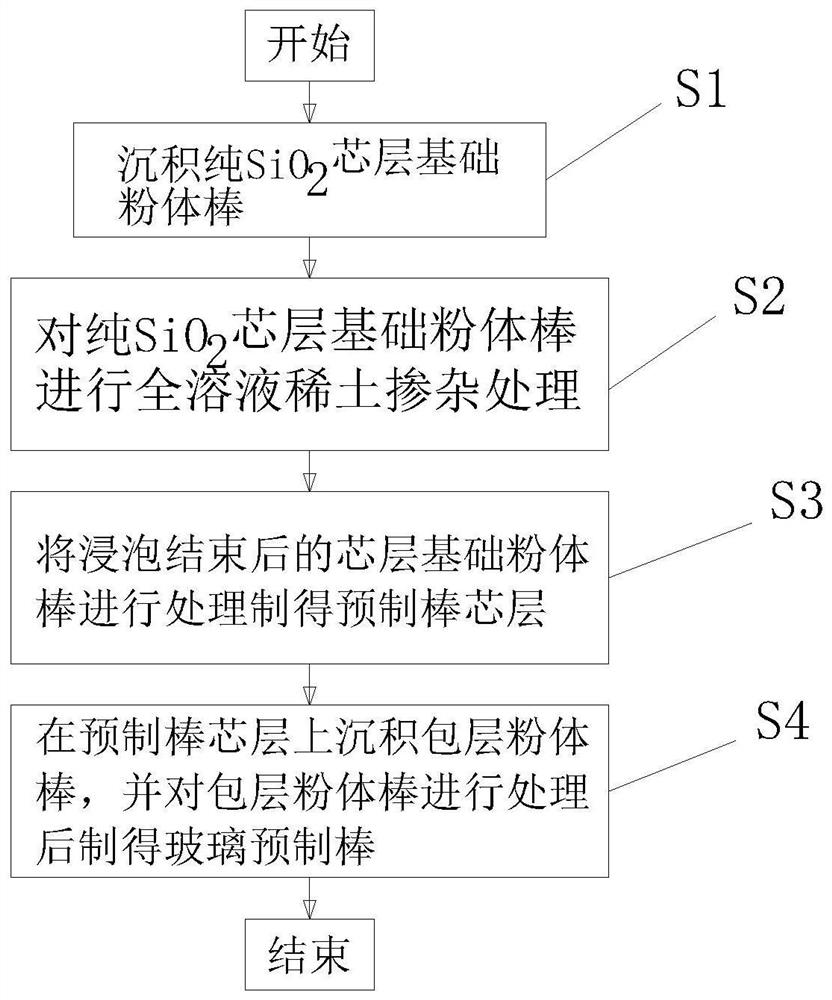

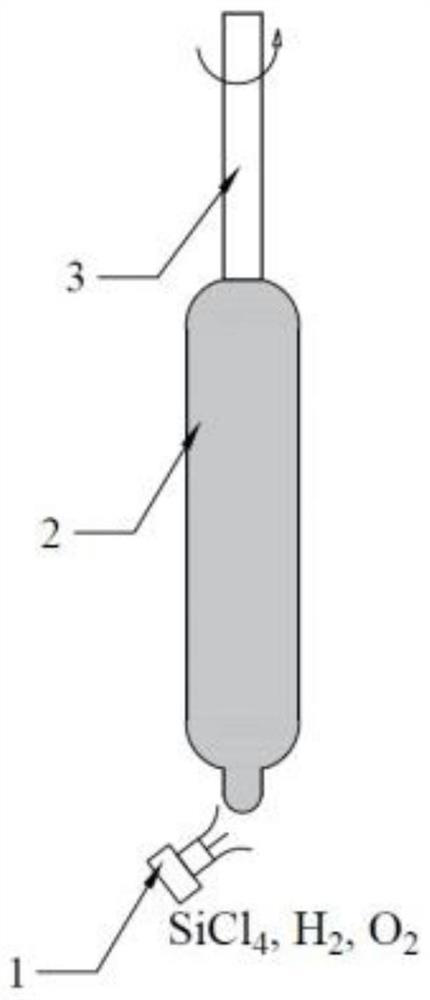

[0044] Use VAD equipment 1 to deposit pure SiO2 core layer base powder rod 2, install the quartz target rod 3, ignite, and immediately start the flame hydrolysis reaction. After the liquid SiCl4 is heated by the gas control cabinet and becomes gaseous, it is transported through a pipeline with a temperature of 100 ° C. To the burner port of VAD equipment 1, gaseous SiCl4 undergoes flame hydrolysis reaction with H2 and O2, and SiO2 powder is generated to adhere to the surface of quartz target rod 3, and the quartz target rod 3 is lifted upward at a lifting speed of 100mm / h, so that the pure SiO2 core layer The basic powder rod 2 continued to grow, and after 10 hours, a pure SiO2 core layer basic powder rod 2 with a diameter of 35mm and a length of 1000mm was obtained, with a density of 0.6g / cm3;

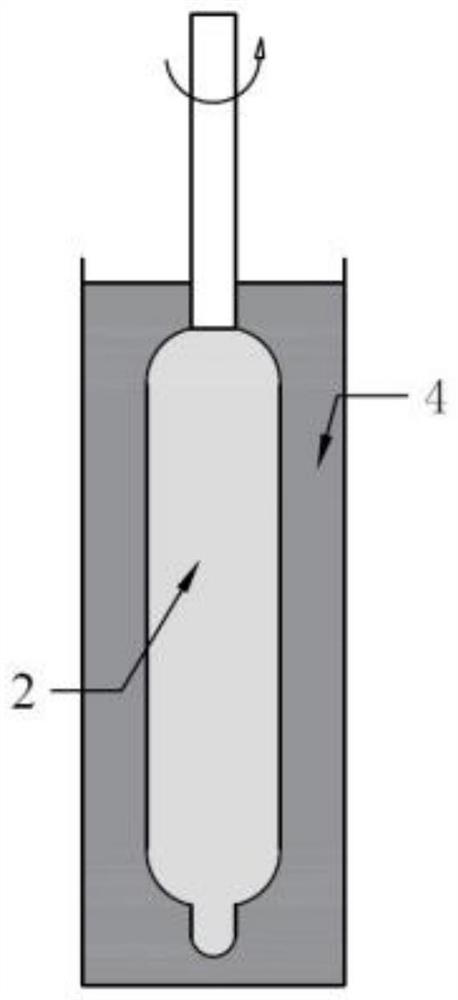

[0045] Dissolve ytterbium chloride, aluminum chloride and phosphoric acid with concentrations of 0.0324mol / L, 0.324mol / L and 0.324mol / L respectively in methanol to prepare rare earth d...

Embodiment 2

[0050] Use VAD equipment 1 to deposit pure SiO2 core layer base powder rod 2, install the quartz target rod 3, ignite, and immediately start the flame hydrolysis reaction. After the liquid SiCl4 is heated by the gas control cabinet and becomes gaseous, it is transported through a pipeline with a temperature of 100 ° C. To the burner port of VAD equipment 1, gaseous SiCl4 undergoes flame hydrolysis reaction with H2 and O2, and SiO2 powder is generated to adhere to the surface of quartz target rod 3, and the quartz target rod 3 is lifted upward at a lifting speed of 100mm / h, so that the pure SiO2 core layer The basic powder rod 2 continued to grow, and after 5 hours, a pure SiO2 core layer basic powder rod 2 with a diameter of 5mm and a length of 1000mm was obtained, with a density of 0.6g / cm3;

[0051] Aluminum chloride and erbium chloride with concentrations of 0.0324mol / L and 1.65mol / L were dissolved in water to prepare rare earth doping solution 4, and pure SiO2 core layer ba...

Embodiment 3

[0056] Use VAD equipment 1 to deposit pure SiO2 core layer base powder rod 2, install the quartz target rod 3, ignite, and immediately start the flame hydrolysis reaction. After the liquid SiCl4 is heated by the gas control cabinet and becomes gaseous, it is transported through a pipeline with a temperature of 100 ° C. To the burner port of VAD equipment 1, gaseous SiCl4 undergoes flame hydrolysis reaction with H2 and O2, and SiO2 powder is generated to adhere to the surface of quartz target rod 3, and the quartz target rod 3 is lifted upward at a lifting speed of 100mm / h, so that the pure SiO2 core layer The basic powder rod 2 continued to grow, and after 15 hours, a pure SiO2 core layer basic powder rod 2 with a diameter of 100mm and a length of 1000mm was obtained, with a density of 0.6g / cm3;

[0057] Dissolve ytterbium chloride, aluminum chloride and phosphoric acid with concentrations of 0.15mol / L, 1.2mol / L and 1.2mol / L respectively in ethanol solution to prepare rare eart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com