A Method Based on Reduction Roasting-Acid Leaching Fly Ash Recycling

A technology of fly ash and resource utilization, applied in chemical instruments and methods, aluminum sulfate, aluminum compounds, etc., can solve problems such as affecting the extraction of trace metals, achieve good economic benefits, improve the degree of resource utilization, and broad market application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

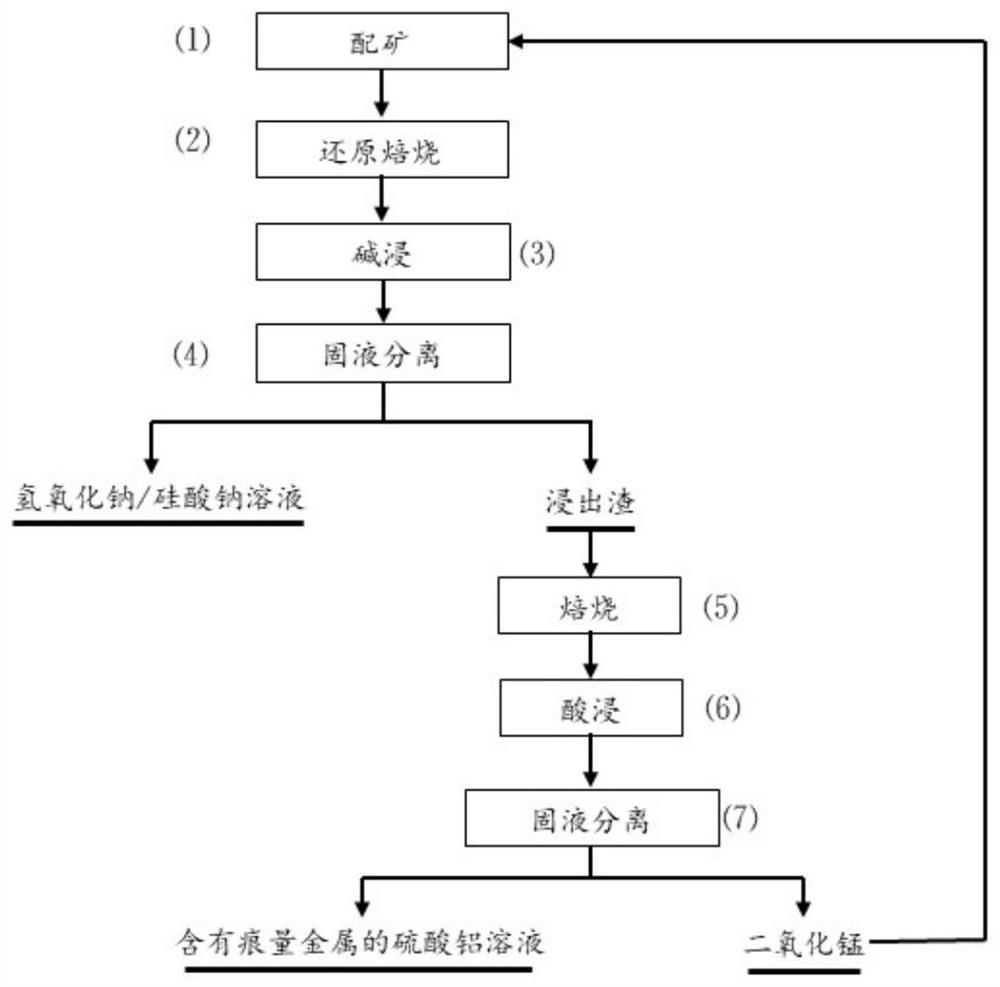

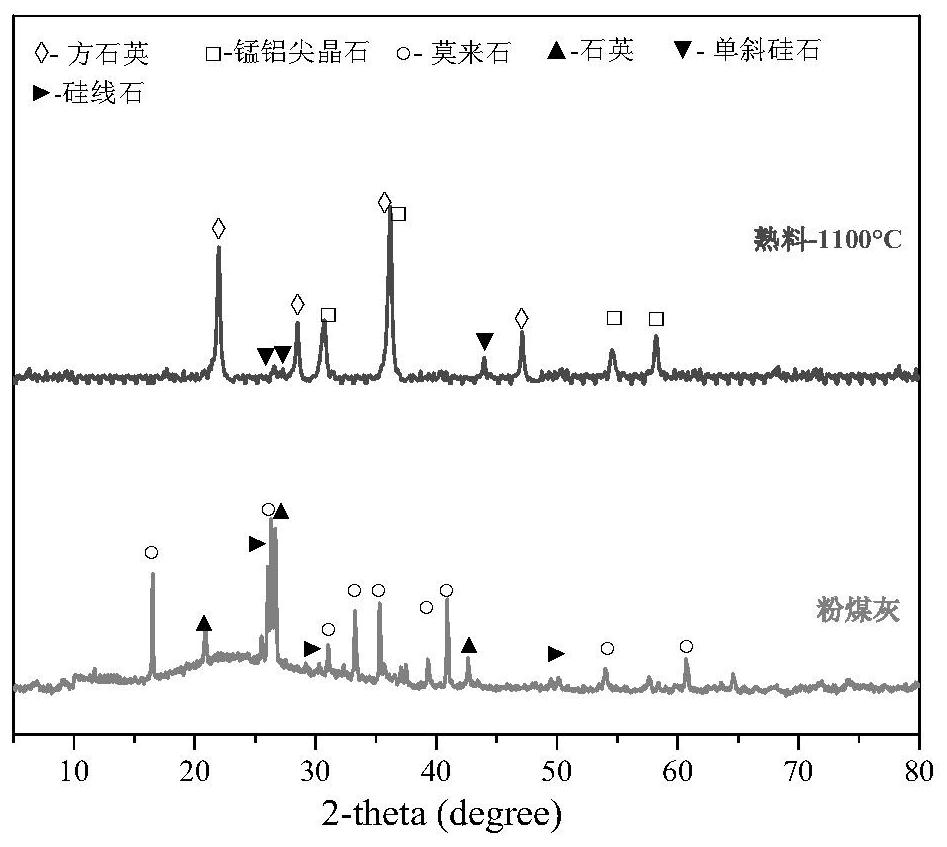

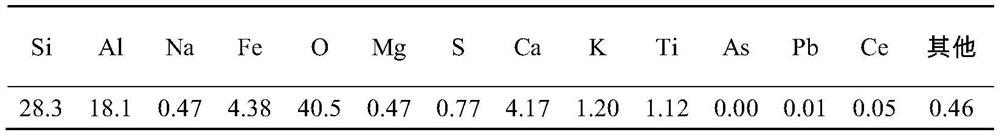

[0045] Combine fly ash with manganese dioxide and coal with MnO 2 :Al 2 o 3 :C=2.2:2:1 for batching, ball milling, pelletizing and drying. Put the pellets in a corundum crucible and roast at 1000°C for 30 minutes in a reducing atmosphere; grind the obtained clinker with a vibrating mill until the d(0.5) particle size is concentrated at about 48.2 μm, and use 2mol / L sodium hydroxide solution at 90°C For leaching fine clinker, the liquid-solid ratio is 5ml / g, and the leaching time is 90min. The dissolution rate of silicon oxide was 77.4%. After solid-liquid separation, the leaching slag was roasted in an oxidizing atmosphere at 300°C for 30 minutes, then ground until the d(0.5) particle size was concentrated at about 16.6 μm, and leached with 2mol / L sulfuric acid solution at a liquid-solid ratio of 5ml / g for 90 minutes at 20°C . Under these conditions, the leaching rate of aluminum was 81.2%, that of cerium was 64.2%, that of strontium was 65.7%, and that of zirconium was 5...

Embodiment 2

[0047] Combine fly ash with manganese dioxide and coal with MnO 2 :Al 2 o 3 :C=2.35:2:1.1 Perform batching, ball milling, pelletizing and drying. Put the pellets in a corundum crucible and roast at 1100°C for 60 minutes in a reducing atmosphere; grind the obtained clinker with a vibrating mill until the d(0.5) particle size is concentrated at about 35.7 μm, and use 3.5mol / L sodium hydroxide solution at 105 The fine clinker is leached at ℃, the liquid-solid ratio is 10ml / g, and the leaching time is 120min. The dissolution rate of silicon oxide was 95.41%. After solid-liquid separation, the leached slag was roasted in an oxidizing atmosphere at 900°C for 45 minutes, then ground until the d(0.5) particle size was concentrated at about 20.7 μm, and leached at 35°C with 3.5mol / L sulfuric acid solution at a liquid-solid ratio of 10ml / g 105min. Under these conditions, the leaching rate of aluminum was 93.2%, that of cerium was 88.2%, that of strontium was 91.7%, and that of zirc...

Embodiment 3

[0049] Combine fly ash with manganese dioxide and coal with MnO 2 :Al 2 o 3 :C=2.5:2:1.2 Perform batching, ball milling, pelletizing and drying. Put the pellets in a corundum crucible and bake at 1200°C for 90 minutes in a reducing atmosphere; grind the obtained clinker with a vibrating mill until the d(0.5) particle size is concentrated at about 44.6 μm, and use 3.5mol / L sodium hydroxide solution at 120 The fine clinker is leached at ℃, the liquid-solid ratio is 15ml / g, and the leaching time is 180min. The dissolution rate of silicon oxide was 71.21%. After solid-liquid separation, the leached slag was roasted in an oxidizing atmosphere at 1000°C for 60 minutes, then ground until the d(0.5) particle size was concentrated at about 37.86 μm, and then leached with 5mol / L sulfuric acid solution at a liquid-solid ratio of 15ml / g at 50°C for 120 minutes . Under these conditions, the leaching rate of aluminum was 74.1%, that of cerium was 58.2%, that of strontium was 69.6%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com