Silicon removal method of silicon-aluminum-containing material

A material, silicon-aluminum technology, applied in the field of desiliconization of silicon-aluminum-containing materials, can solve the problems of difficult desiliconization of high-silicon and aluminum-containing minerals, low silicon oxide dissolution rate, etc., and achieves low cost, good economic benefits, and removal rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

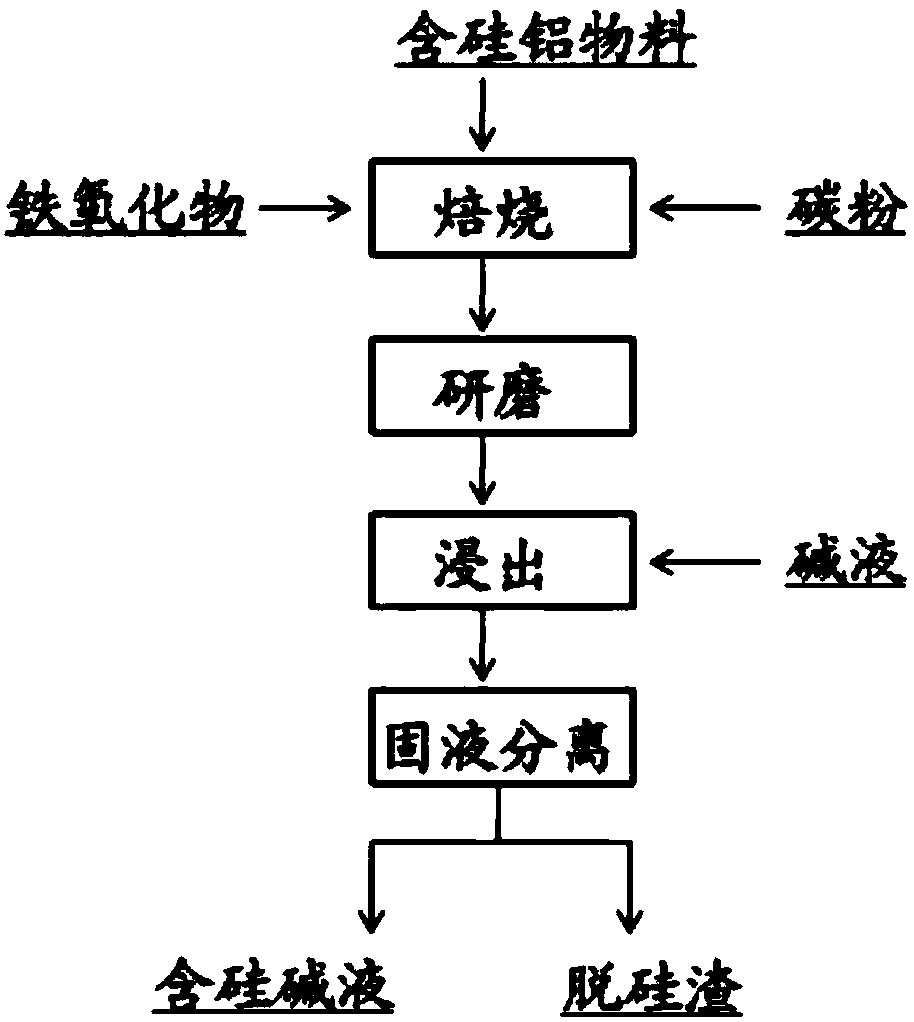

Method used

Image

Examples

Embodiment 1

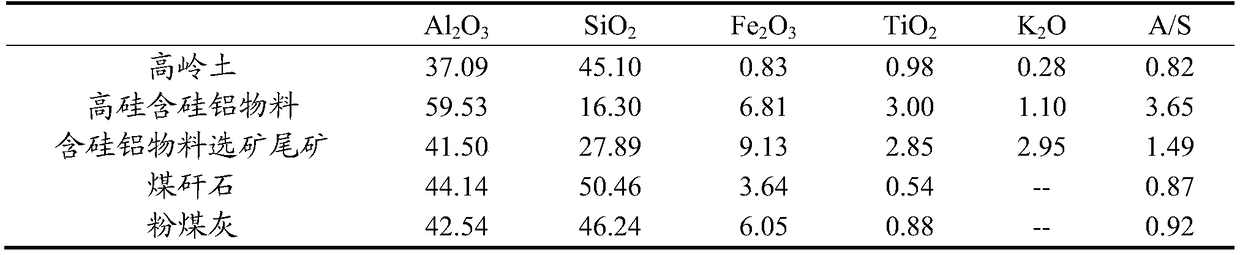

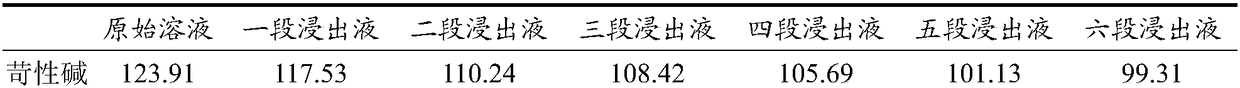

[0033] According to the molar ratio of iron oxide: alumina in kaolin: carbon = 2.4:4:1.2 for batching and pelletizing. The dried pellets are placed in a corundum crucible, roasted in a reducing atmosphere, and the atmosphere is adjusted with coke. The roasting temperature is 1100°C, and the roasting time is 60 minutes; the obtained roasted clinker is finely ground to about d(0.5)=43.52 μm, and the roasted clinker is desiliconized by alkali leaching with sodium hydroxide alkali solution, the leaching temperature is 125°C, liquid-solid The ratio is 5, the caustic alkali concentration is 125g / L, and the leaching time is 120min. Under these conditions, the dissolution rate of silicon oxide is 91.13%, and the aluminum-silicon ratio of the leaching slag is 9.11.

Embodiment 2

[0035] According to the molar ratio of iron oxide: alumina in kaolin: carbon = 2.4:4:1.2 for batching and pelletizing. The dried pellets are placed in a corundum crucible, roasted in a reducing atmosphere, and the atmosphere is adjusted with coke. The roasting temperature is 1100°C, and the roasting time is 60 minutes; the obtained roasted clinker is finely ground to about d(0.5)=43.52 μm, and the roasted clinker is desiliconized by alkali leaching with sodium hydroxide alkali solution, the leaching temperature is 110°C, liquid-solid The ratio is 3, the caustic alkali concentration is 125g / L, and the leaching time is 120min. Under these conditions, the dissolution rate of silicon oxide is 87.04%, and the aluminum-silicon ratio of the leaching slag is 6.25.

Embodiment 3

[0037] According to the molar ratio of iron oxide: aluminum oxide: carbon = 2.4:4:1.2 in the high-silicon-containing silicon-aluminum material is used for batching and pelletizing. The dried pellets are placed in a corundum crucible, roasted in a reducing atmosphere, and the atmosphere is adjusted with coke. The roasting temperature is 1100°C, and the roasting time is 60 minutes; the obtained roasted clinker is finely ground to about d(0.5)=28.52 μm, and the roasted clinker is desiliconized by alkali leaching with sodium hydroxide alkali solution, the leaching temperature is 110°C, liquid-solid The ratio is 10, the caustic alkali concentration is 125g / L, and the leaching time is 120min. Under these conditions, the dissolution rate of silicon oxide is 77%, and the aluminum-silicon ratio of the leaching slag is 8.57.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com