Anode foil and preparation method thereof

A technology of anode foil and aluminum foil, which is applied in the manufacture of electrolytic capacitors, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of low loss, undetectable, short life, etc. The effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation process of the present invention is:

[0050] Multi-stage pretreatment—one-stage formation—KD1 (liquid feed)—two-stage formation—three-stage formation—KD2 (liquid feed)—four-stage formation—five-stage formation—KD3 (liquid feed)—six-stage formation— Heat treatment 1—intermediate treatment 1—repair 1—heat treatment 2—intermediate treatment 2—repair 2—heat treatment 3—repair 3—post-treatment—drying.

[0051] The main solutes of the chemical conversion solution include: citric acid and citrate, adipic acid and adipate, ammonium dihydrogen phosphate, boric acid and borate, phosphoric acid.

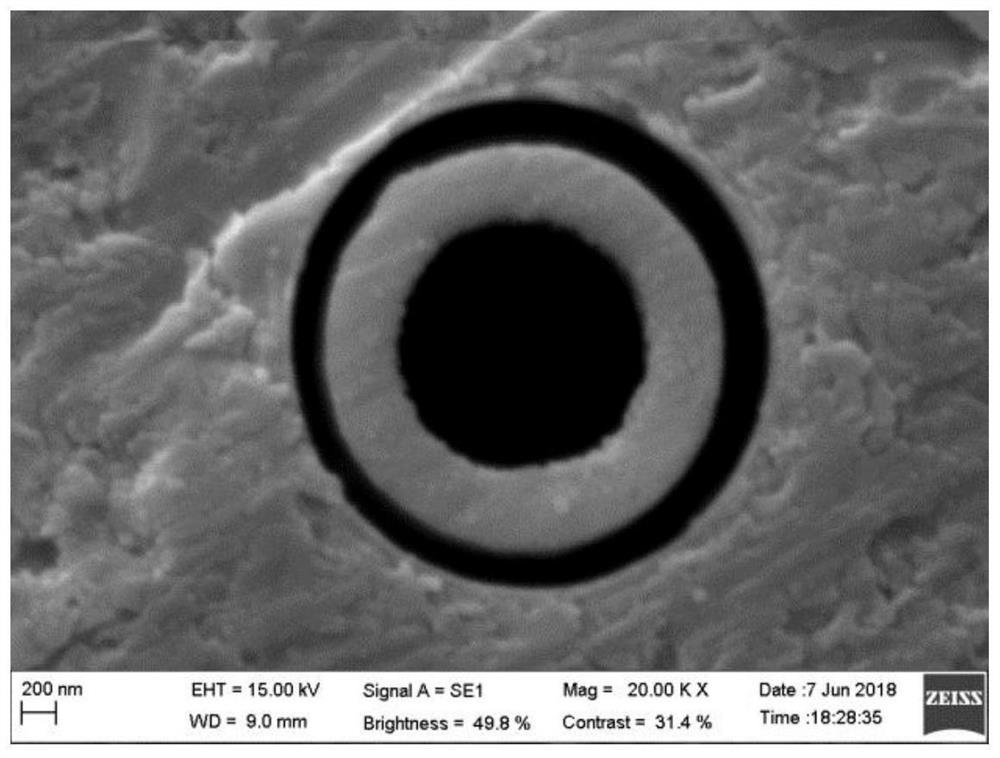

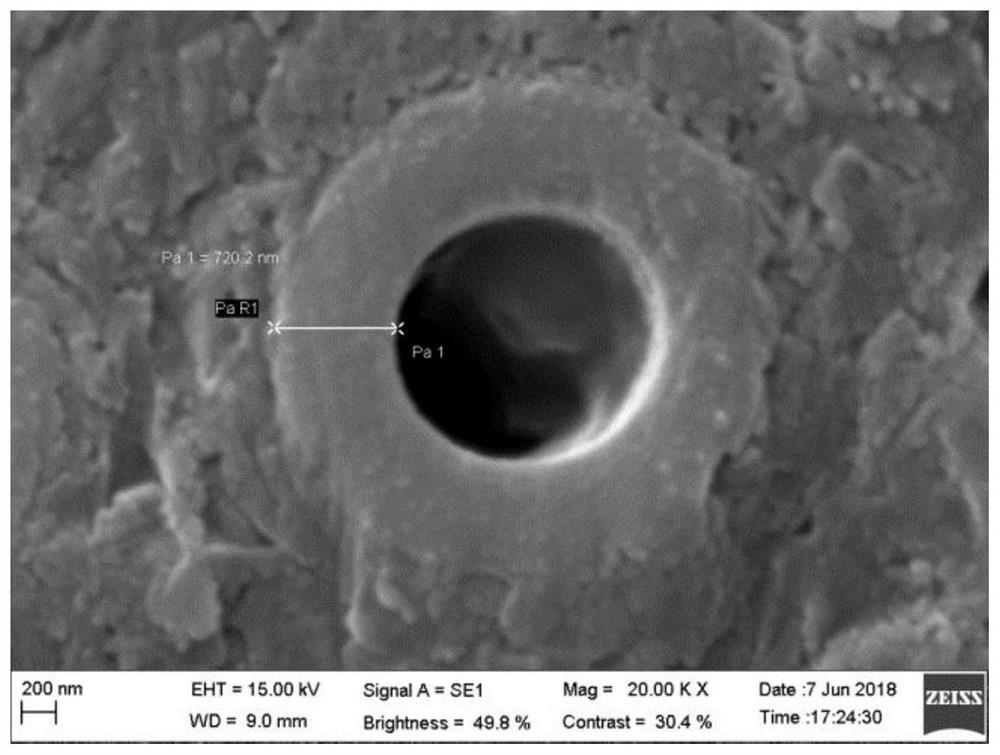

[0052] The present invention can prepare a semi-amorphous oxide film by using special bath composition and process flow, and the oxide film has characteristics such as low loss, low ESR (impedance), and ripple current resistance, and the anode produced by this method Foil is water resistant and performs better.

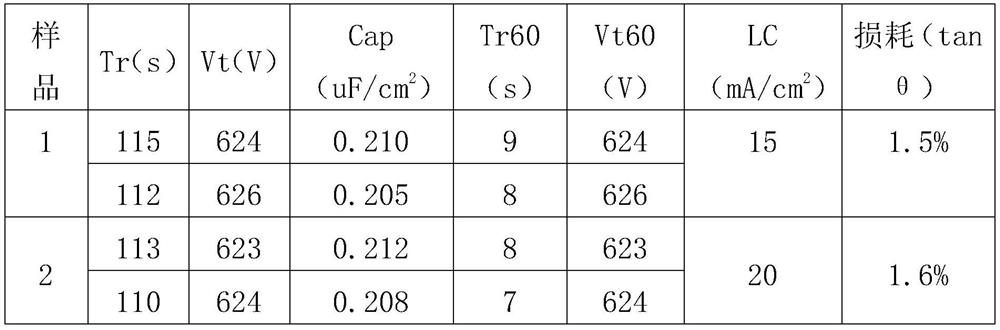

Embodiment 1

[0092] The specific operation steps are as follows:

[0093] (1) Pretreatment 1: Treat the aluminum foil in pure water at 90-98°C for 10 minutes; dry;

[0094] (2) Pretreatment 2: Treat the aluminum foil that has undergone pretreatment 1 in pure water at 80-98°C for 12 minutes, and dry it;

[0095] (3) Primary chemical formation: the aluminum foil that has undergone pretreatment 2 is subjected to the primary chemical formation solution containing 20wt% ammonium adipate and adipate, and the temperature is 50°C, and the current density is 50mA / cm 2 , into 5min, the applied voltage is 80V;

[0096] (4) KD1 (the first liquid feeding): feed the aluminum foil after primary formation in 10wt% ammonium adipate solution for 5 minutes, the temperature of the bath solution is 25°C, the voltage is 25V, and the current is 1550A.

[0097] (5) Secondary chemical formation: the aluminum foil treated in step (3) is subjected to a secondary electric treatment at a temperature of 55 ℃, curren...

Embodiment 2

[0136] The specific operation steps are as follows:

[0137] (1) Pretreatment 1: After treating the aluminum foil in pure water at 95°C for 10 minutes, dry it;

[0138] (2) Pretreatment 2: Treat the aluminum foil that has undergone pretreatment 1 in pure water at 95°C for 6 minutes, and then dry it;

[0139] (3) Pretreatment 3: Treat the aluminum foil that has undergone pretreatment 2 in pure water at 90°C for 10 minutes, and then dry it;

[0140] (4) Primary formation: the aluminum foil that has undergone pretreatment 3 is subjected to the first-stage electrification treatment in the primary formation solution containing 10wt% citric acid and citrate, the temperature is 60°C, and the current density is 50mA / cm 2 , into 5min, the applied voltage is 80V;

[0141] (5) KD1 (the first liquid feeding): Feed the first-stage formed aluminum foil in 2.0wt% phosphoric acid solution for 5 minutes, the temperature of the bath solution is 30°C, the voltage is 25V, and the current is 155...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com