Preparation method of dodecahedral hollow cobalt-nickel selenide/iron oxyhydroxide composite catalyst

A technology of iron oxyhydroxide and composite catalyst, which is applied in the directions of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor conductivity of iron oxyhydroxide alone, and achieves environmental protection, pollution-free and improved preparation cycle. Oxygen evolution reaction ability and stability, and the effect of improving OER performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

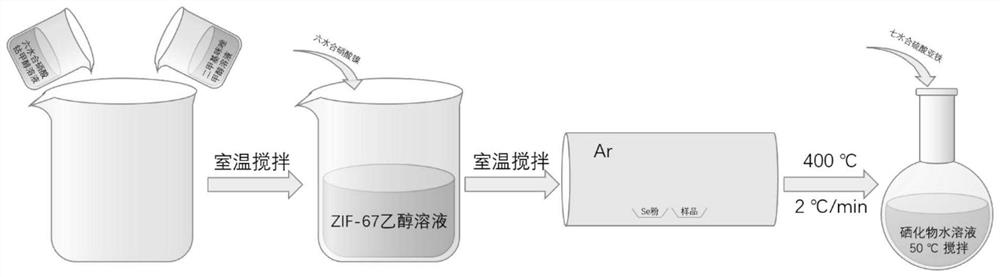

[0059] A preparation method of a cobalt-nickel-based catalyst material is realized in the following steps:

[0060] (1) Preparation of cobalt-based metal-organic framework materials: 1.74g of cobalt nitrate hexahydrate and 1.97g of dimethylimidazole were dissolved in 150ml of anhydrous methanol; 1200r / min, finally centrifuged and washed 3 times with deionized water and absolute ethanol, and dried in vacuum at 70°C for 10h to obtain a cobalt-based metal-organic framework material;

[0061] (2) Preparation of cobalt-nickel layered double metal hydroxide material: Weigh 40mg of cobalt-based metal-organic framework material and ultrasonically disperse it in 50mL of absolute ethanol, then quickly add 100mg of nickel nitrate hexahydrate and stir at room temperature for 4h, Centrifuge and wash with absolute ethanol, and finally dry in vacuum at 70°C for 10 hours to obtain a cobalt-nickel layered double hydroxide material;

[0062] (3) Cobalt-nickel layered double hydroxide selenizat...

Embodiment 2

[0065] The difference between this example and Example 1 is that 25 mg of ferrous sulfate heptahydrate was added to the solution and stirred, and other parameters and specific implementation steps were the same as in Example 1.

Embodiment 3

[0067] The difference between this example and Example 1 is that 35 mg of ferrous sulfate heptahydrate was added to the solution and stirred, and other parameters and specific implementation steps were the same as in Example 1.

[0068] figure 1 For the preparation of (Co,Ni)Se 2 / C@FeOOH) flow chart.

[0069] The above steps 1 to 4 can be prepared to obtain (Co, Ni)Se 2 / C@FeOOH). As a comparison, step 4 is not carried out, and only steps 1 to 3 are carried out to obtain (Co,Ni)Se 2 / C. Only carry out steps 1 to 2 to obtain CoNiLDH. Only carry out step 1, ZIF-67 can be obtained.

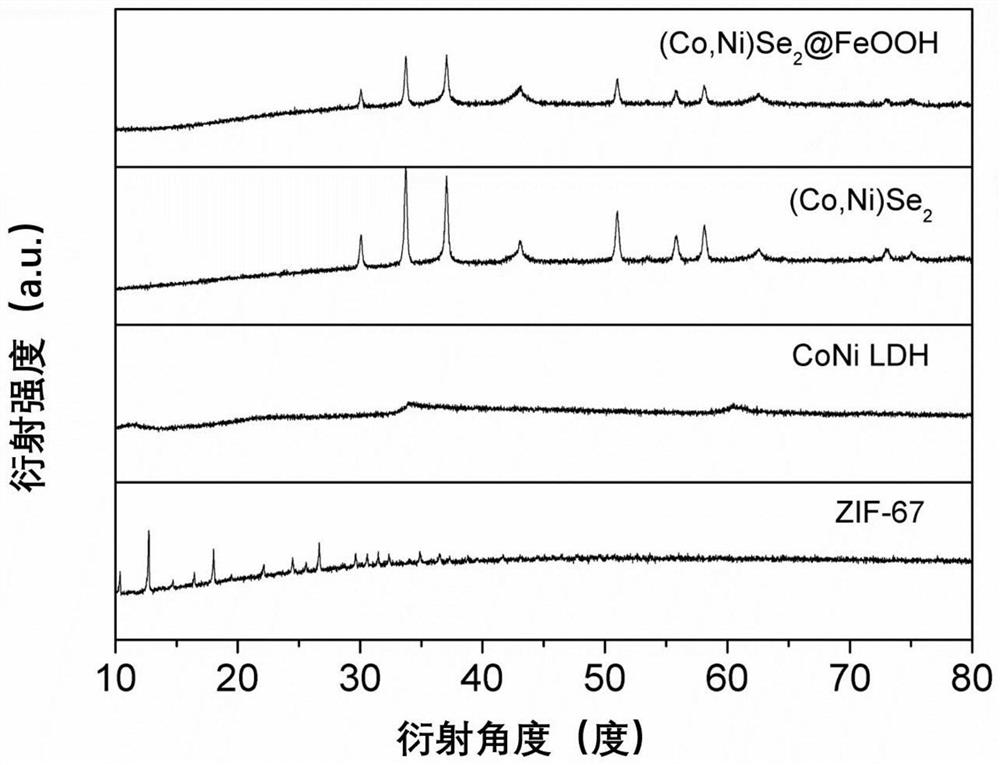

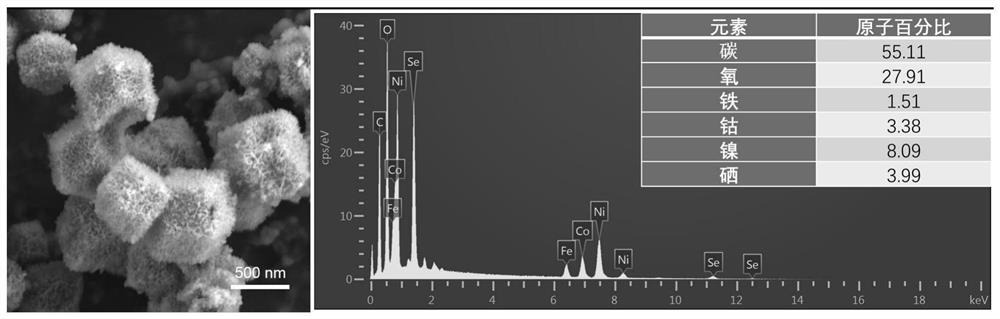

[0070] figure 2 (Co, Ni)Se prepared for Example 2 2 / C@FeOOH), (Co,Ni)Se 2 / C, CoNi LDH, the XRD pattern of ZIF-67, as can be seen from the figure that (Co, Ni)Se prepared by the present invention 2 / C@FeOOH), (Co,Ni)Se 2 / C, CoNiLDH, and ZIF-67 are all pure phases, and (Co,Ni)Se 2 / C@FeOOH), (Co,Ni)Se 2 / C has the same diffraction peaks at different 2θ angles, which indicates that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com