Carbon cloth loaded nitrogen-doped graphene material as well as preparation method and application thereof

A technology of nitrogen-doped graphene and carbon cloth, applied in chemical instruments and methods, catalyst activation/preparation, water/sludge/sewage treatment, etc., can solve the problems of low catalytic efficiency, insufficient stability, and catalyst recyclability and other problems, to achieve excellent catalytic activity, improve electron transfer ability, and facilitate the effect of catalytic degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention discloses a method for preparing a carbon cloth-supported nitrogen-doped graphene material, which comprises the following steps:

[0031] (1) First disperse the nitrogen source into an organic solvent, then add non-noble metal-MOF nanoparticles as a precursor, and stir and mix at 60°C to obtain a composite dispersion; wherein, the mass of the nitrogen source and the non-noble metal-MOF The ratio is (1~20):1;

[0032] (2) Then, the composite dispersion liquid is added dropwise on the acidified carbon cloth, and after pyrolysis, the carbon cloth supported nitrogen-doped graphene material is obtained.

[0033] Specifically, the nitrogen source is one or two or more of urea, dicyandiamide, melamine, acetonitrile and polyaniline.

[0034] Specifically, the organic solvent is one or two or more of methanol, ethanol, isopropanol, ethylene glycol, polyethylene glycol, and the like.

[0035] Specifically, the non-noble metal-MOF is one or more of MOF-5 (Zn), ZIF-...

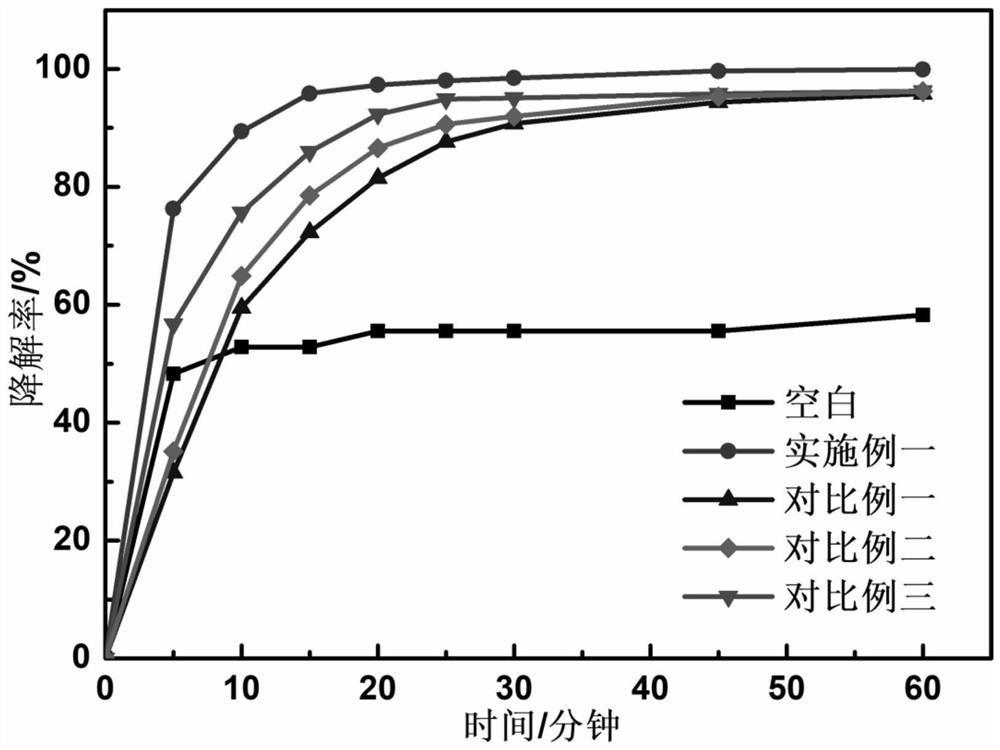

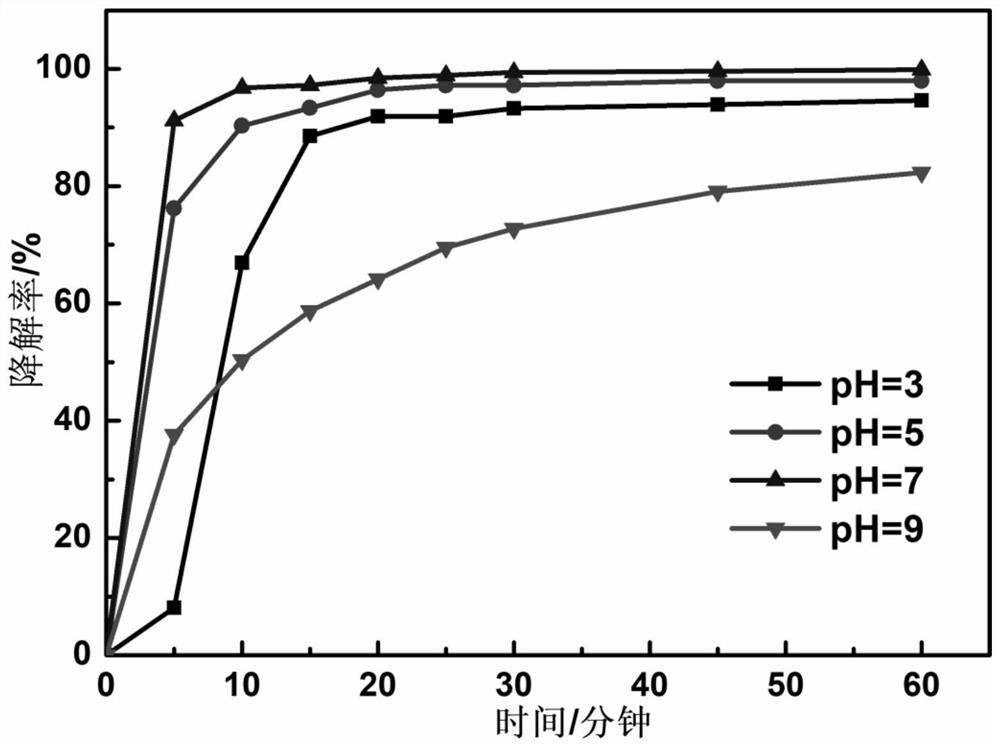

Embodiment 1

[0037] The invention discloses a method for preparing a carbon cloth-supported nitrogen-doped graphene material, which comprises the following steps:

[0038] (1) Dissolve 5.231g of dicyandiamide in 167mL of ethanol, stir and heat to dissolve at 60°C, then add 0.5231g of MIL-101(Fe), that is, the mass ratio of nitrogen source to MOF is 10:1; after uniform stirring for 4 hours A light orange solution was obtained, namely MIL-101(Fe) / dicyandiamide composite dispersion.

[0039] (2) Concentrate the carbon cloth with acid and 2.5g KMnO at 50°C 4 After soaking in the solution for 5 min, washing and drying, the treated carbon cloth was obtained. Wherein concentrated mixed acid is the concentrated phosphoric acid of 5ml and the concentrated hydrochloric acid of 45ml.

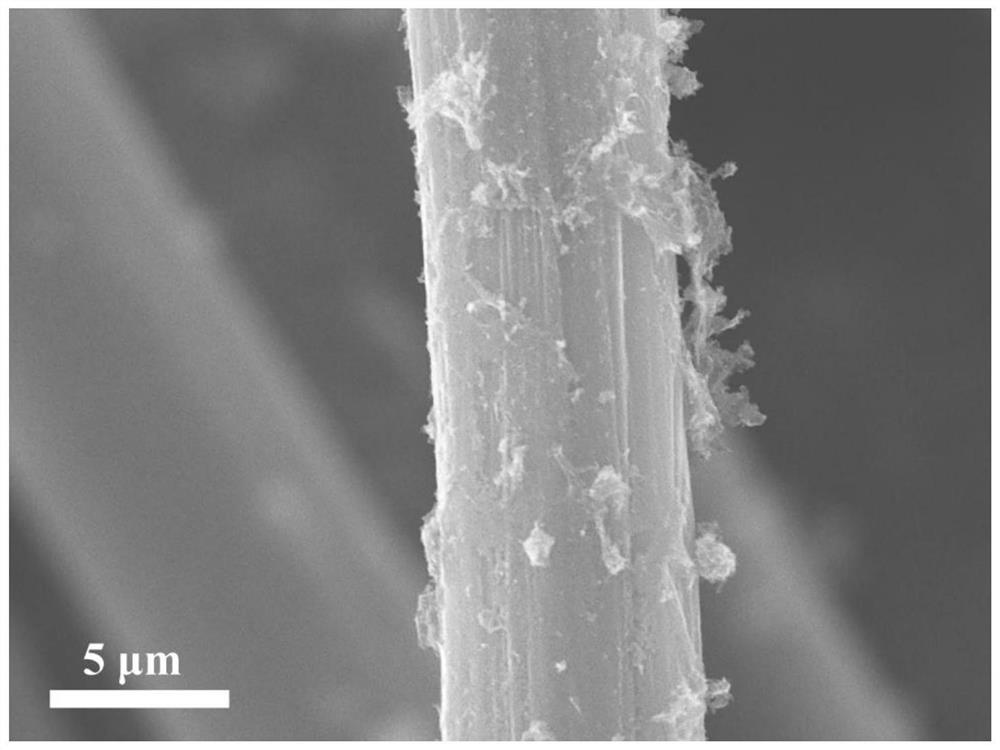

[0040] (3) Add the dispersion of MIL-101(Fe) / dicyandiamide compound dropwise onto the treated carbon cloth. After the MIL-101(Fe) / dicyandiamide compound is loaded on the carbon cloth, place Pyrolysis in the quartz b...

Embodiment 2

[0042] The invention discloses a method for preparing a carbon cloth-supported nitrogen-doped graphene material, which comprises the following steps:

[0043] (1) Dissolve 7.068g of dicyandiamide in 226mL of ethylene glycol, stir and heat to dissolve at 60°C, then add 0.3534g of MOF-5(Zn), that is, the mass ratio of nitrogen source to MOF is 20:1; stir evenly for 4 After hours, a white solution was obtained, that is, the MOF-5(Zn) / dicyandiamide composite dispersion.

[0044] (2) Concentrate the carbon cloth with acid and 2.5g KMnO at 50°C 4 After soaking in the solution for 5 min, washing and drying, the treated carbon cloth was obtained. Wherein the concentrated mixed acid is the concentrated phosphoric acid of 5ml and the concentrated nitric acid of 45ml.

[0045](3) Add the MOF-5(Zn) / dicyandiamide composite dispersion dropwise onto the treated carbon cloth, and the MIL-101(Fe) / dicyandiamide composite is loaded on the carbon cloth and placed in a tube furnace Pyrolysis in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com