Metal sulfide and preparation method and application thereof

A metal sulfide and sulfur source technology, applied in molybdenum sulfide, electrochemical generators, structural parts, etc., can solve the problems of low coulombic efficiency, capacity drop, poor cycle performance, etc., to achieve expansion of diversity, maintenance of stability, Avoid the effect of clustering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: a kind of metal sulfide and preparation method thereof:

[0049] (1) Mix 1.6g molybdenum trioxide and 3g imidazole into 250mL deionized aqueous solution, heat to 100°C and reflux for 10h to generate white powder molybdenum-based precursor;

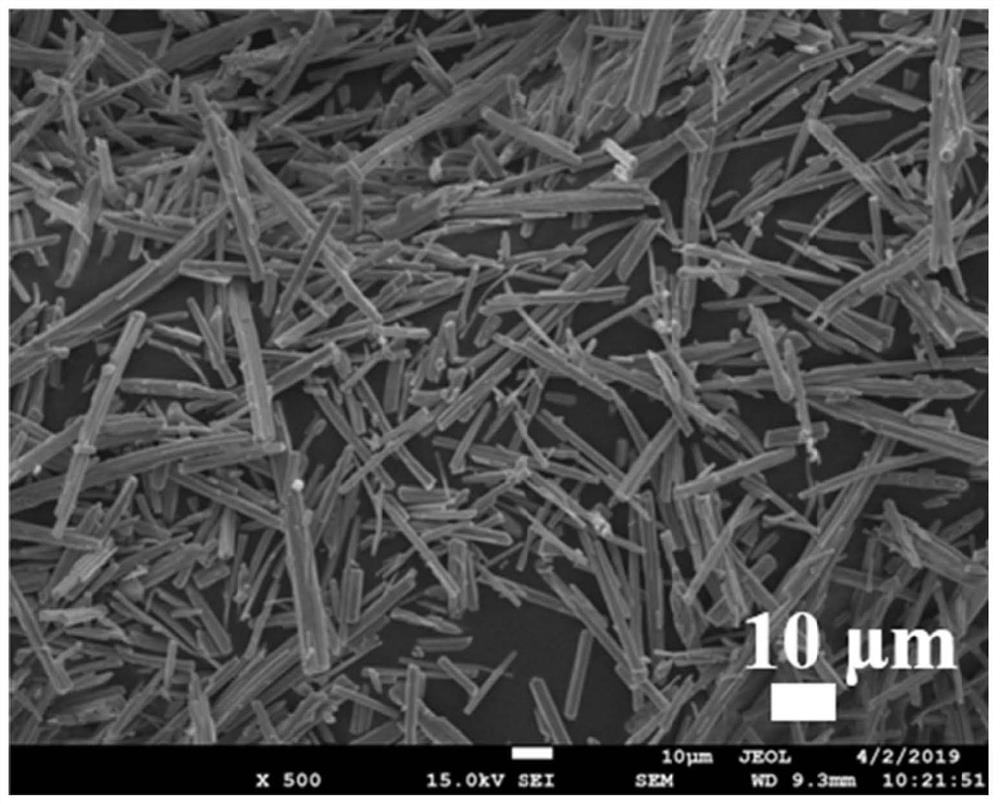

[0050] (2) Centrifuge the white powder molybdenum-based precursor obtained in step (1) at a speed of 7000r / min for 5min, wash the solid once with deionized water and centrifuge again, repeat this step 3 times, remove the supernatant and Dry at 80°C for 12 hours to obtain a purified molybdenum-based precursor; scan the purified molybdenum-based precursor with an electron microscope, and the results are as follows figure 1 shown.

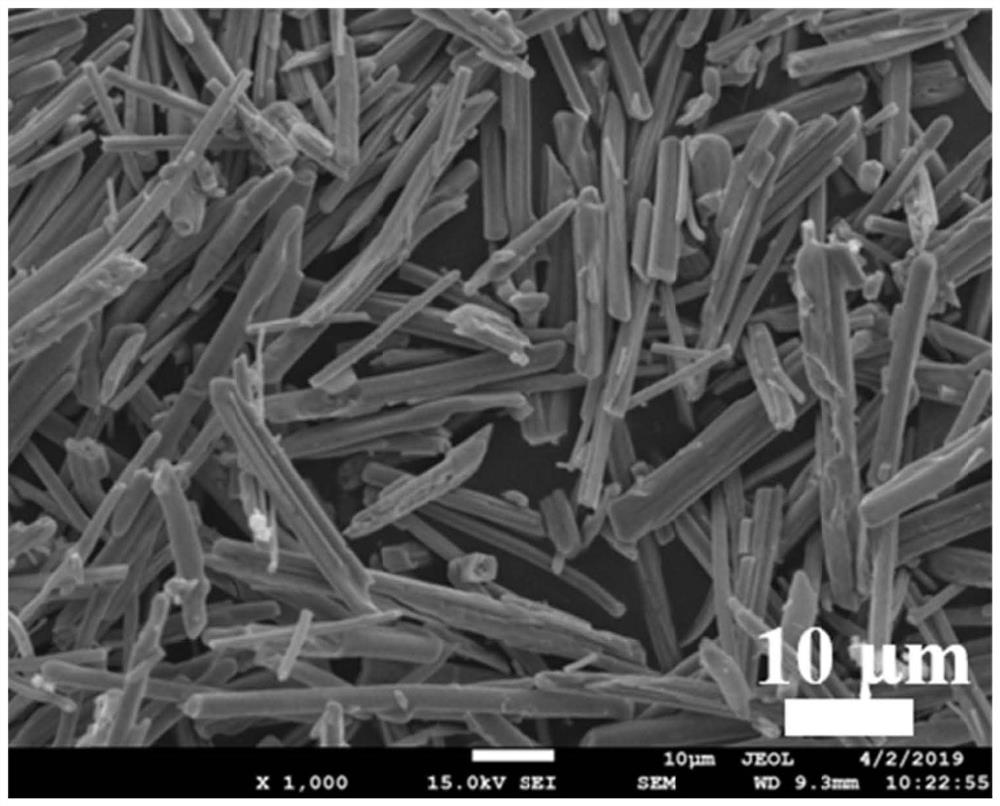

[0051] (3) Heat the molybdenum-based precursor obtained in step (2) to 600°C at a heating rate of 5°C / min in a nitrogen atmosphere, keep it warm for 2h, and obtain a pretreated molybdenum-based precursor after cooling; The body was scanned by electron microscope, and the results were as foll...

Embodiment 2

[0058] Embodiment 2: a kind of metal sulfide and preparation method thereof:

[0059] (1) Mix 2.0g molybdenum trioxide and 5g imidazole into 250mL deionized aqueous solution, heat to 110°C and reflux for 12h to generate white powder molybdenum-based precursor;

[0060] (2) Centrifuge the white powder molybdenum-based precursor obtained in step (1) at a speed of 7000r / min for 3min, wash the solid once with deionized water and centrifuge again, repeat this step 5 times, remove the supernatant and Drying at 90°C for 12 hours to obtain a purified molybdenum-based precursor;

[0061] (3) Heating the molybdenum-based precursor obtained in step (2) to 500°C at a heating rate of 3°C / min in a nitrogen atmosphere, keeping it warm for 3h, and obtaining a pretreated molybdenum-based precursor after cooling;

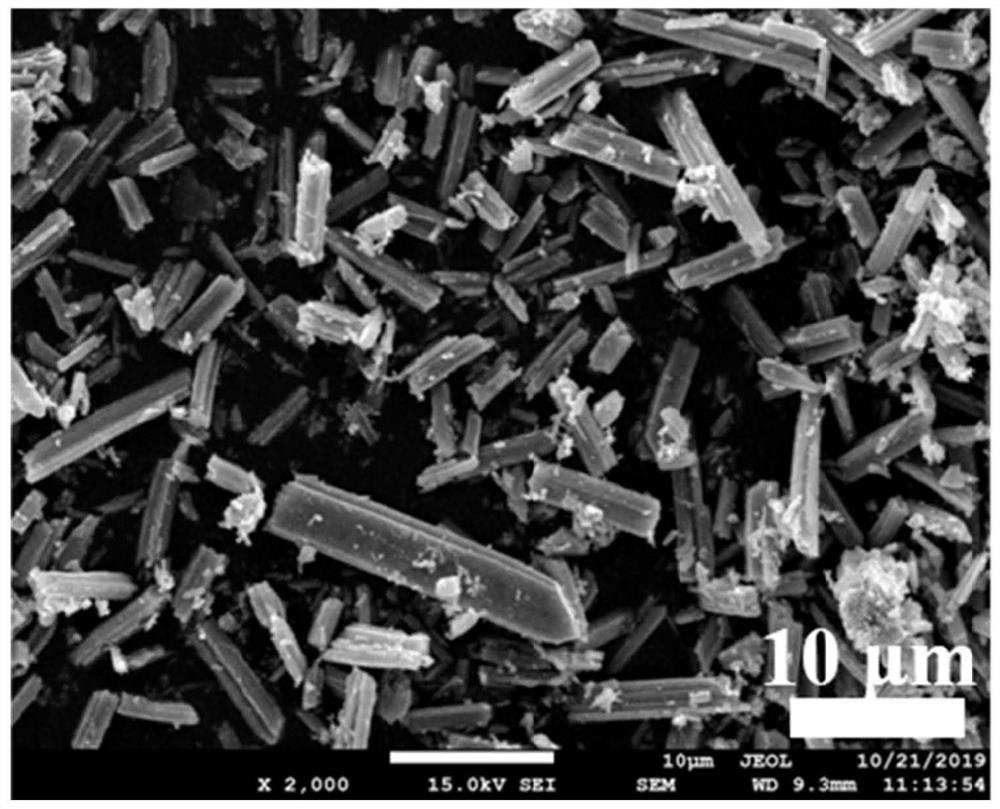

[0062] (4) Take 0.2g of the pretreated molybdenum-based precursor obtained in step (3), put it into a mortar and grind it, then put it into the temperature center area of the tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com