Preparation method of high-sensitivity piezoresistive strain sensor

A strain sensor and high-sensitivity technology, applied in the field of strain sensors, can solve the problem of lack of small strain sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

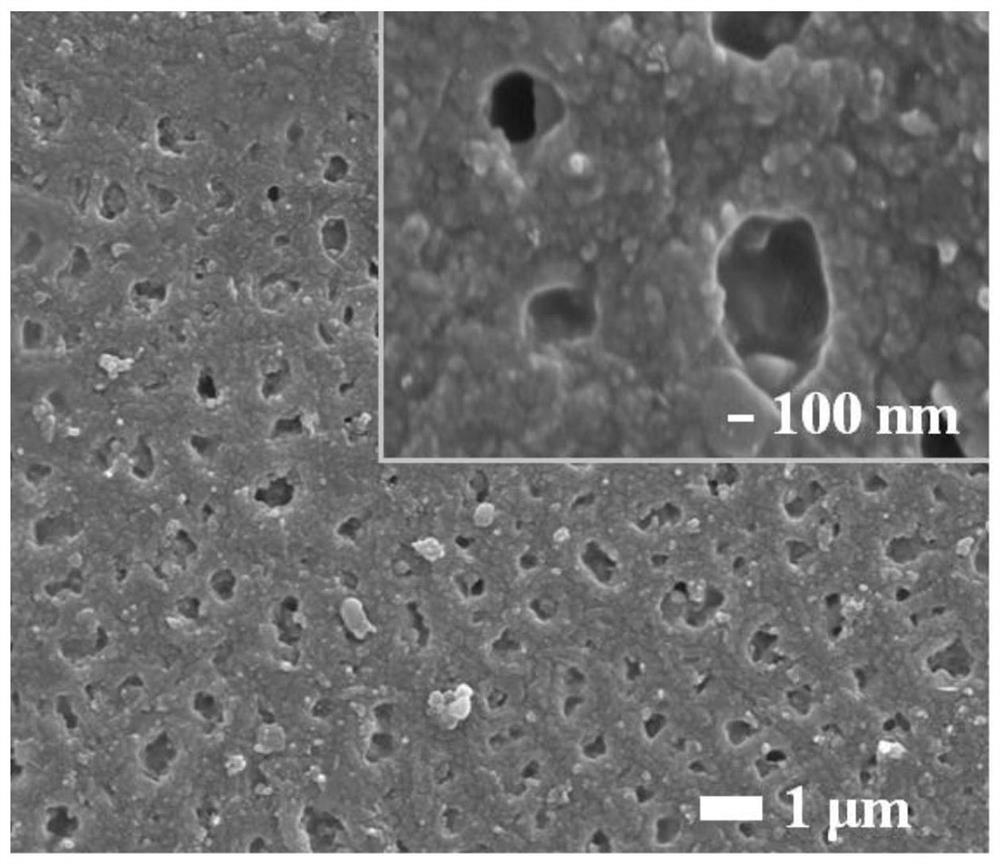

Image

Examples

Embodiment 1

[0029] A preparation method of a high-sensitivity piezoresistive strain sensor, comprising the steps of:

[0030] (1) Add 10g of distilled water to 1.0g of polyvinyl alcohol powder, first swell at 55°C for 65min, then stir and heat at 80°C for 3h until the polymer is completely dissolved to obtain polyvinyl alcohol gel, cool to room temperature for later use.

[0031] (2) 1 mL of glutaraldehyde solution with a concentration of 1.0 wt.% was added dropwise to 10 g of polyvinyl alcohol gel, stirred evenly, and left at room temperature for 10 h to prepare polyvinyl alcohol / glutaraldehyde gel.

[0032] (3) Prepare 1 mL of ferric chloride aqueous solution with a concentration of 2.0 g / mL, stir and drop the ferric chloride solution into 10 g of polyvinyl alcohol / glutaraldehyde gel (ferric chloride and polyvinyl alcohol / pentane The mass ratio of dialdehyde gel is 1:5), and immediately transferred to the bottom area after stirring evenly, the area is 10*10cm 2 Freeze at -5°C for 10 ho...

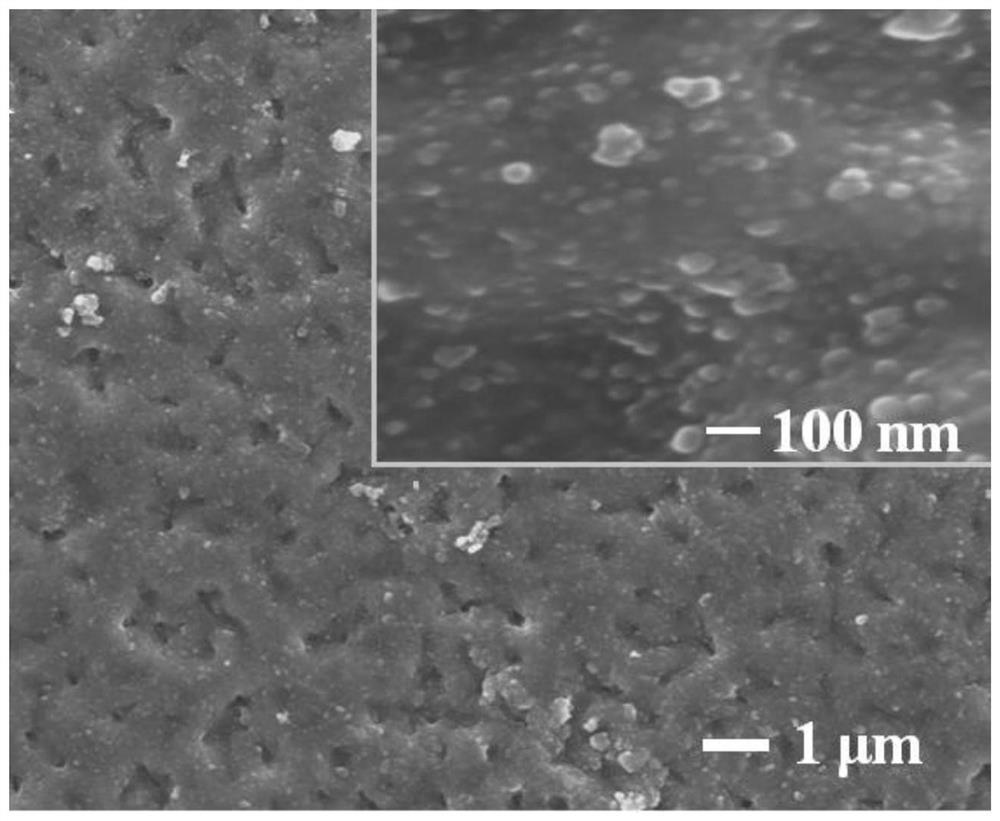

Embodiment 2

[0035] A preparation method of a high-sensitivity piezoresistive strain sensor, comprising the steps of:

[0036] (1) Add 10 g of distilled water to 2.0 g of polyvinyl alcohol powder, first swell at 65°C for 70 minutes, then stir and heat at 95°C for 3 hours until the polymer is completely dissolved to obtain a polyvinyl alcohol gel, and cool to room temperature for later use.

[0037] (2) 1 mL of glutaraldehyde solution with a concentration of 5.0 wt.% was added dropwise to 10 g of polyvinyl alcohol gel, stirred evenly, and left at room temperature for 10 h to prepare polyvinyl alcohol / glutaraldehyde gel.

[0038] (3) Prepare 1 mL of ferric chloride aqueous solution with a concentration of 5.0 g / mL, stir and drop the ferric chloride solution into 10 g of polyvinyl alcohol / glutaraldehyde gel (ferric chloride and polyvinyl alcohol / pentane The mass ratio of dialdehyde gel is 1:2), and immediately transferred to the bottom area after stirring evenly, the area is 10*10cm 2 Freeze...

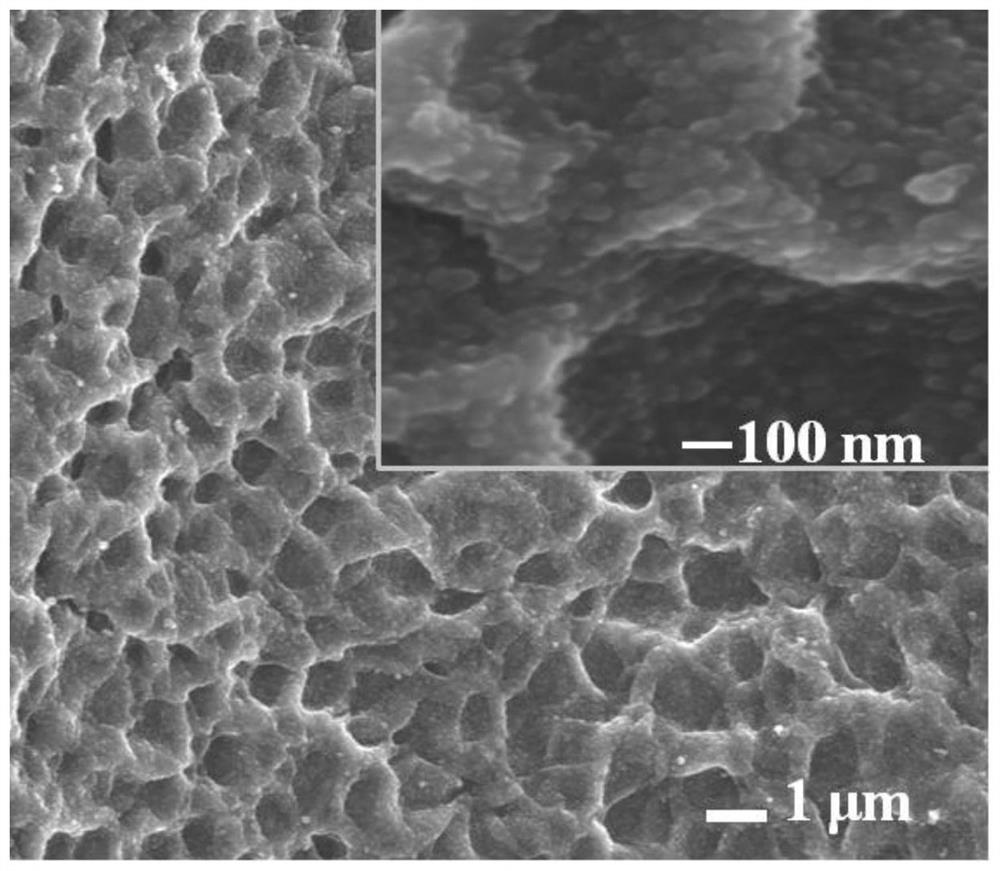

Embodiment 3

[0041] A preparation method of a high-sensitivity piezoresistive strain sensor, comprising the steps of:

[0042] (1) Add 8g of distilled water to 1.2g of polyvinyl alcohol powder, first swell at 60°C for 60min, then stir and heat at 90°C for 3h until the polymer is completely dissolved to obtain polyvinyl alcohol gel, cool to room temperature for later use.

[0043] (2) 1 mL of glutaraldehyde solution with a concentration of 1.0 wt.% was added dropwise to 10 g of polyvinyl alcohol gel, stirred evenly, and left at room temperature for 10 h to prepare polyvinyl alcohol / glutaraldehyde gel.

[0044](3) Prepare 1 mL of ferric chloride aqueous solution with a concentration of 5.0 g / mL, stir and drop the ferric chloride solution into 10 g of polyvinyl alcohol / glutaraldehyde gel (ferric chloride and polyvinyl alcohol / pentane The mass ratio of dialdehyde gel is 1:2), and immediately transferred to the bottom area after stirring evenly, the area is 10*10cm 2 Freeze at -5°C for 10 h in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com