Industrial tail gas treatment system

A technology for treating system and industrial tail gas, which is applied in the direction of climate change adaptation, climate sustainability, chemical/physical process, etc. It can solve problems such as unsatisfactory single-stage treatment effect of tail gas, low emission requirements, unfulfilled emissions, etc., and achieve maintenance Low cost, improved bonding strength, and high dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

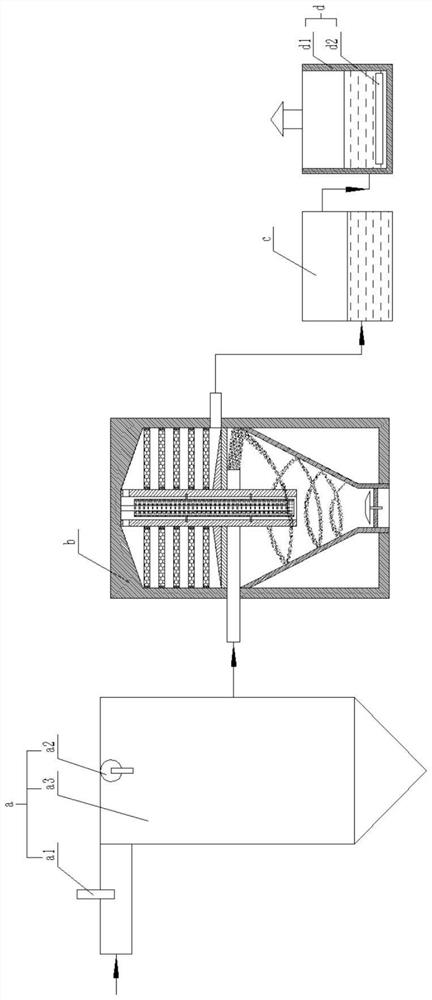

[0020] The industrial tail gas treatment system includes a pretreatment unit a, a tail gas catalytic device b, a desulfurization device c, and a degreasing device d arranged sequentially along the direction of industrial waste gas transportation; the pretreatment unit a includes water mist generators connected in sequence device a1, charge generating device a2, aerosol mixing reactor a3, the desulfurization device c includes a pool body 1, and the water pool 1 is filled with saturated NaHCO 3 solution; the degreasing device d includes a pool body two d1, and several cooling pipes d2 are arranged in the pool body two d1;

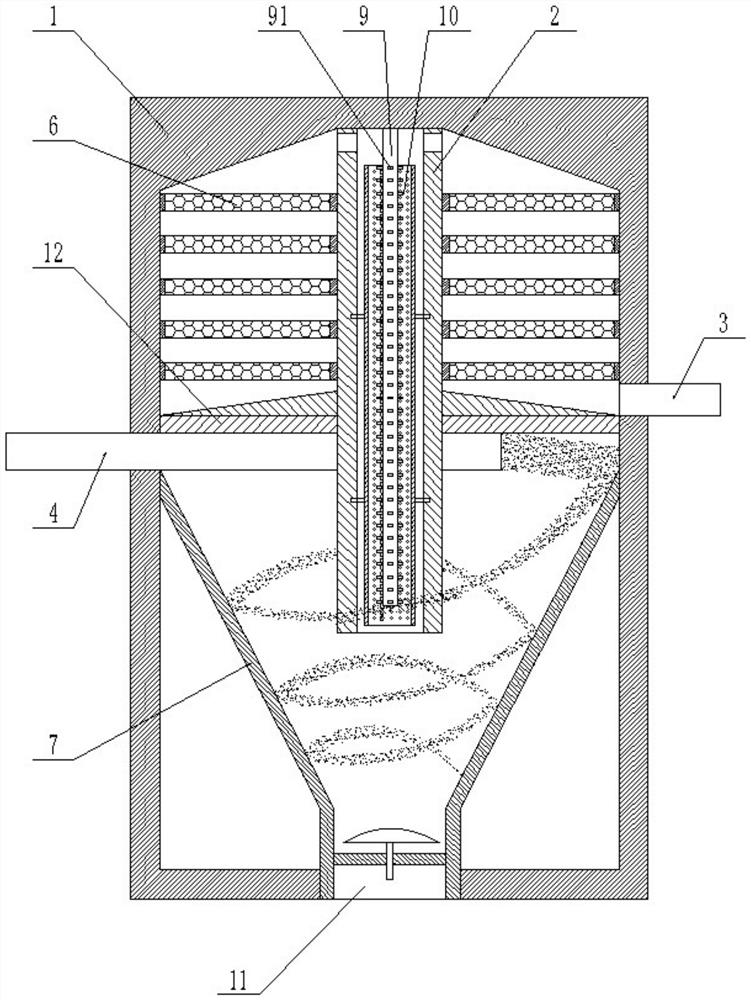

[0021] The tail gas catalytic device b includes a tower body 1, and the middle part of the tower body 1 is provided with a partition plate 12, and the partition plate 12 divides the tower body 1 into an upper catalytic purification area and a lower dust separation area, and the upper catalytic purification area The gas zone and the lower dust separation zone ...

Embodiment 2

[0023] The industrial tail gas treatment system includes a pretreatment unit a, a tail gas catalytic device b, a desulfurization device c, and a degreasing device d arranged sequentially along the direction of industrial waste gas transportation; the pretreatment unit a includes water mist generators connected in sequence device a1, charge generating device a2, aerosol mixing reactor a3, the desulfurization device c includes a pool body 1, and the water pool 1 is filled with saturated NaHCO 3solution; the degreasing device d includes a pool body two d1, and several cooling pipes d2 are arranged in the pool body two d1;

[0024] The tail gas catalytic device b includes a tower body 1, and the middle part of the tower body 1 is provided with a partition plate 12, and the partition plate 12 divides the tower body 1 into an upper catalytic purification area and a lower dust separation area, and the upper catalytic purification area The gas zone and the lower dust separation zone a...

Embodiment 3

[0027] The industrial tail gas treatment system includes a pretreatment unit a, a tail gas catalytic device b, a desulfurization device c, and a degreasing device d arranged sequentially along the direction of industrial waste gas transportation; the pretreatment unit a includes water mist generators connected in sequence device a1, charge generating device a2, aerosol mixing reactor a3, the desulfurization device c includes a pool body 1, and the water pool 1 is filled with saturated NaHCO 3 solution; the degreasing device d includes a pool body two d1, and several cooling pipes d2 are arranged in the pool body two d1;

[0028] The tail gas catalytic device b includes a tower body 1, and the middle part of the tower body 1 is provided with a partition plate 12, and the partition plate 12 divides the tower body 1 into an upper catalytic purification area and a lower dust separation area, and the upper catalytic purification area The gas zone and the lower dust separation zone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com