Activated carbon for preparing catalyst for calcium carbide process vinyl chloride and preparation method of activated carbon

A technology for the preparation of activated carbon and the method of vinyl chloride, which is applied in chemical instruments and methods, catalysts for physical/chemical processes, and preparation of hydrogen halide addition, etc., which can solve the problems of weak adsorption capacity of non-polar molecules and improvement of catalyst reaction activity. , to achieve the effect of less environmental harm, reducing environmental harm and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

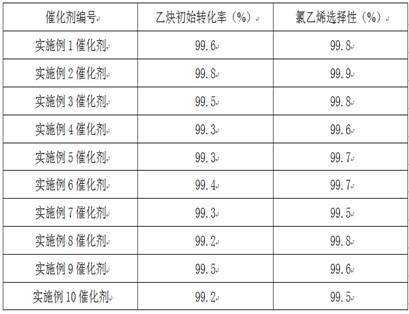

Examples

Embodiment 1

[0064] A method for preparing active carbon as a catalyst for vinyl chloride in the calcium carbide process, comprising: selecting the active carbon, pickling, and impregnating.

[0065] The selection steps of activated carbon, the selected activated carbon is mesoporous activated carbon, the specific surface area is 800㎡ / g, the carbon tetrachloride adsorption rate is 45%, the ash value is 10%, the mesopore diameter is 18Å, and the mesoporosity is 30%. .

[0066] The mesoporous pores of mesoporous activated carbon serve as channels for the effective loading of active substances, which can ensure that there are still enough channels to transport reactants after adsorption.

[0067] In the pickling step, the mesoporous activated carbon is pickled with 1 mol / L dilute acid, and after pickling, the mesoporous activated carbon is washed with deionized water. After washing, the mesoporous activated carbon is acidic, and its pH is 3.

[0068] In the pickling step, the pickling temper...

Embodiment 2

[0077] A method for preparing active carbon as a catalyst for vinyl chloride in the calcium carbide process, comprising: selecting the active carbon, pickling, and impregnating.

[0078] In the selection of activated carbon, the selected activated carbon is mesoporous activated carbon with a specific surface area of 900㎡ / g, a carbon tetrachloride adsorption rate of 50%, an ash value of 11%, a mesopore diameter of 25 Å, and a mesoporosity of 40 %.

[0079] The mesoporous pores of mesoporous activated carbon serve as channels for the effective loading of active substances, which can ensure that there are still enough channels to transport reactants after adsorption.

[0080] The pickling step is to use 1 mol / L phosphoric acid to pickle the mesoporous activated carbon, the pickling temperature is 50°C, and the pickling time is 3h; Activated carbon is acidic with a pH of 4.

[0081] Wherein, the weight ratio of mesoporous activated carbon: dilute acid is 1:3.

[0082] The pic...

Embodiment 3

[0088] A method for preparing activated carbon as a catalyst for vinyl chloride in the calcium carbide process, comprising: selecting the activated carbon, pickling, and impregnating.

[0089]In the selection step of activated carbon, the selected activated carbon is mesoporous activated carbon with a specific surface area of 1000㎡ / g, an adsorption rate of carbon tetrachloride of 55%, an ash value of 13%, a mesopore diameter of 30 Å, and a mesoporosity of 50 %.

[0090] The mesoporous pores of mesoporous activated carbon serve as channels for the effective loading of active substances, which can ensure that there are still enough channels to transport reactants after adsorption.

[0091] The pickling step is to use 1 mol / L phosphoric acid to pickle the mesoporous activated carbon, the pickling temperature is 70°C, and the pickling time is 6h; Activated carbon is acidic with a pH of 5.

[0092] Wherein, the weight ratio of mesoporous activated carbon: dilute acid is 1:12. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com