Flexible polyurethane-based carbon nano composite electromagnetic shielding material and preparation method thereof

An electromagnetic shielding material and carbon nanocomposite technology, applied in the field of materials, can solve the problems of heavy weight and easy corrosion of electromagnetic protection materials, and achieve the effect of light weight and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

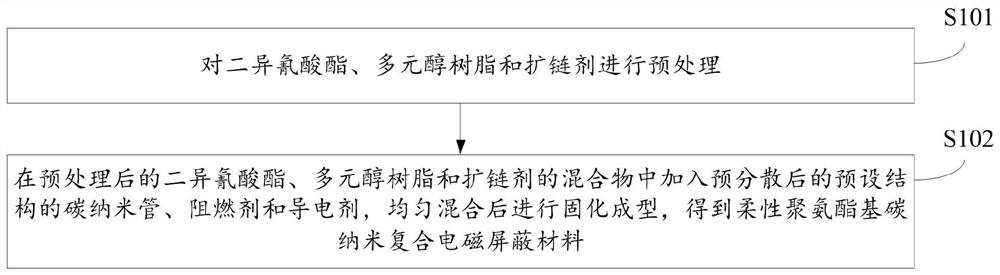

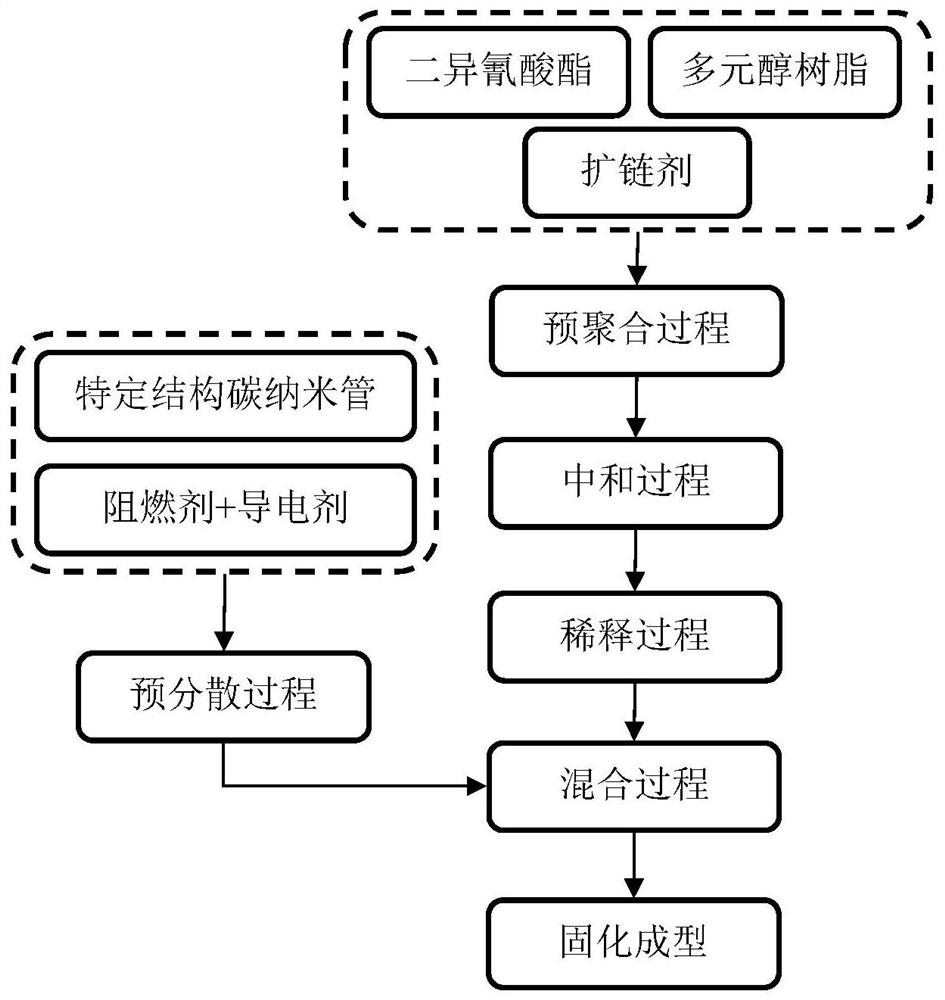

[0024] The first embodiment of the present invention provides a method for preparing a flexible polyurethane-based carbon nanocomposite electromagnetic shielding material, see figure 1 , the method includes:

[0025] S101, pretreating diisocyanate, polyol resin and chain extender;

[0026] S102. Add pre-dispersed carbon nanotubes with preset structures, flame retardants and conductive agents to the mixture of pretreated diisocyanate, polyol resin and chain extender, mix uniformly, and perform curing and molding to obtain flexible polyurethane Carbon nanocomposite electromagnetic shielding material.

[0027] The embodiment of the present invention is based on the uniform array of carbon nanotubes for polyurethane resin modification formula design, by synchronously adding flame retardants, catalysts, stabilizers, anti-aging agents, etc. to make them well dispersed in the polyurethane resin matrix, to achieve the best Mixing process treatment conditions, emphatically realize th...

specific Embodiment 1

[0045] (1) Preparation of carbon nanotubes with uniform length: Utilize CVD method, by adjusting methane gas flow rate (300~400sccm range), reaction temperature 750 ℃, reaction time 50~60min time range adjustment, catalyst Fe nano film 2nm~3nm, obtain uniform Carbon nanotubes with a length of 200-300 μm, weighing 1-3 g.

[0046] (2) Weigh (by mass parts) 200-300g of polyester polyol resin;

[0047] (3) Weigh diisocyanate TDI, 100-150g; weigh dimethylol propionic acid (DMPA) 10-20g;

[0048] (4) Weigh 10-50g of neutralizer, 300-500g of solvent water and a small amount of acetone;

[0049] (5) Weigh the flame retardant aluminum oxide hydrate and zinc oxide, 40-50g in total according to the mass ratio of 1:1; weigh 20-30g of the conductive agent;

[0050] (6) Diisocyanate and chain extender in (2) polyol resin and (3) are placed in the 1000ml flask equipped with stirrer, thermometer and reflux condenser, under N 2 Under protection, react at 80-120°C for 120-180 minutes to obta...

specific Embodiment 2

[0056] (1) Preparation of uniform length carbon nanotubes: using CVD method, by adjusting the methane gas flow rate in the range of 350sccm to 450sccm, the reaction temperature in the temperature range of 700°C to 750°C, and the reaction time of 80min to 100min, the catalyst Fe nano film is 2nm to 5nm range, the length of the arrayed carbon nanotubes is 300 μm to 400 μm, and the weight is 3 to 5 g.

[0057] (2) Weighing (in parts by mass): weigh 300-500 g of polyether polyol resin;

[0058] (3) Weigh the diisocyanate HDI, 200-300g, and weigh the small molecule chain extender TETA, 30-50g;

[0059] (4) Weigh 10-50g of neutralizing agent, 500-1000g of solvent deionized water and a small amount of acetone;

[0060] (5) Weigh 50-100g of flame retardant aluminum hydroxide and zinc oxide in total, and weigh 30-50g of silver powder conductive agent;

[0061] (6) polyol resin in (2) and diisocyanate and chain extender in (3) are placed in the 1000ml flask equipped with stirrer, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com