Irradiation-resistant and high-temperature-resistant phenylene silicone rubber and preparation method thereof

A phenylene ether silicone rubber, radiation-resistant technology, applied in the field of rubber preparation, can solve the problems of complex rubber components, cumbersome preparation process, etc., and achieve the effect of improving high temperature resistance, excellent toughness and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

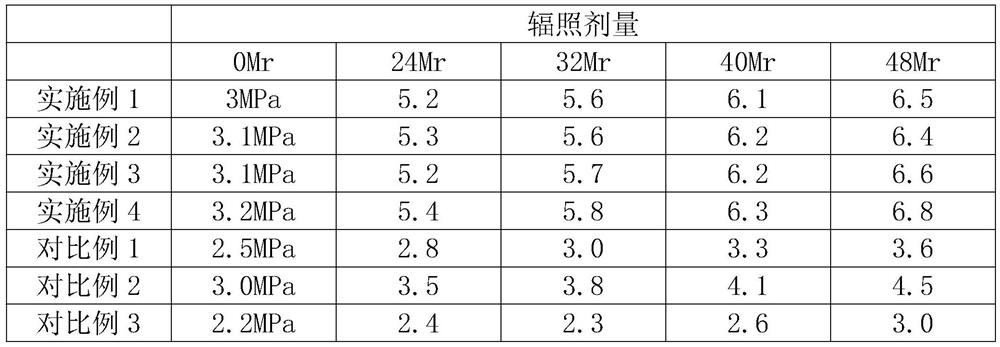

Examples

Embodiment 1

[0029] A radiation-resistant, high-temperature-resistant phenylene ether silicone rubber, comprising the following raw materials in parts by weight: 85 parts of composite phenylene ether silicone rubber, 10 parts of radiation-resistant auxiliary agent, 10 parts of gadolinium chloride, 3 parts of zinc stearate, 3 parts of NAPM [N-(4-phenylaminophenyl) methacrylamide], 5 parts of carbon black;

[0030] The radiation-resistant, high-temperature-resistant phenylene ether silicone rubber is made by the following method:

[0031] Add the composite phenylene oxide silicone rubber, radiation-resistant additive, gadolinium chloride, zinc stearate, NAPM [N-(4-phenylaminophenyl) methacrylamide] and carbon black into the mixer in sequence, First mix at 45°C for 30 minutes to prepare the mixture, then heat-treat the mixture at 190°C for 1 hour, add it to a vulcanizer after cooling, and vulcanize for 10 minutes at 150°C under a pressure of 25 MPa to obtain radiation-resistant and high-tempe...

Embodiment 2

[0041] A radiation-resistant, high-temperature-resistant phenylene ether silicone rubber, comprising the following raw materials in parts by weight: 90 parts of composite phenylene ether silicone rubber, 12 parts of radiation-resistant additives, 14 parts of gadolinium chloride, 3 parts of zinc stearate, 3 parts of NAPM [N-(4-phenylaminophenyl) methacrylamide], 6 parts of carbon black;

[0042] The radiation-resistant, high-temperature-resistant phenylene ether silicone rubber is made by the following method:

[0043] Add the composite phenylene oxide silicone rubber, radiation-resistant additive, gadolinium chloride, zinc stearate, NAPM [N-(4-phenylaminophenyl) methacrylamide] and carbon black into the mixer in sequence, First mix at 45°C for 30 minutes to prepare the mixture, then heat-treat the mixture at 190°C for 1 hour, add it to a vulcanizer after cooling, and vulcanize for 10 minutes at 150°C under a pressure of 25 MPa to obtain radiation-resistant and high-temperature...

Embodiment 3

[0053] A radiation-resistant, high-temperature-resistant phenylene ether silicone rubber, comprising the following raw materials in parts by weight: 95 parts of composite phenylene ether silicone rubber, 14 parts of radiation-resistant additives, 16 parts of gadolinium chloride, 4 parts of zinc stearate, 4 parts of NAPM [N-(4-phenylaminophenyl) methacrylamide], 8 parts of carbon black;

[0054] The radiation-resistant, high-temperature-resistant phenylene ether silicone rubber is made by the following method:

[0055]The compound phenylene oxide silicone rubber, radiation-resistant additives, gadolinium chloride, zinc stearate, NAPM [N-(4-phenylaminophenyl)methacrylamide] and carbon black are added to the mixer in turn, The mixture was first mixed at 45°C for 30min to obtain a mixture, then the mixture was heat-treated at 190°C for 1h, cooled and then added to a vulcanizer for vulcanization at 150°C and a pressure of 25MPa for 10min to obtain a radiation-resistant, high-temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com