Interface agent and preparation method thereof

A technology of interface agent and defoamer, which is applied in the direction of coating, metal-free paint, etc., can solve the problems of interface agent standing time exceeding the effective use time, long construction time, waste of raw materials, etc., to prolong the effective use time , the effect of accelerating the evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

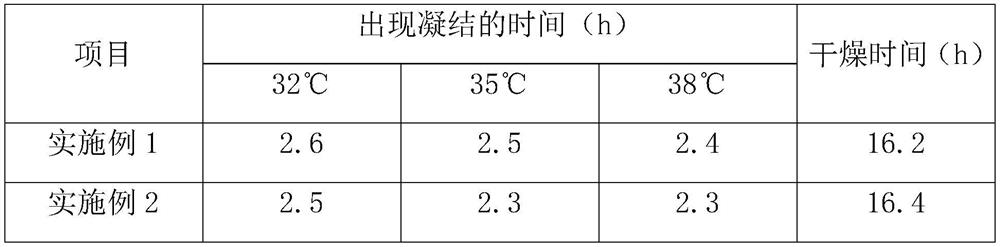

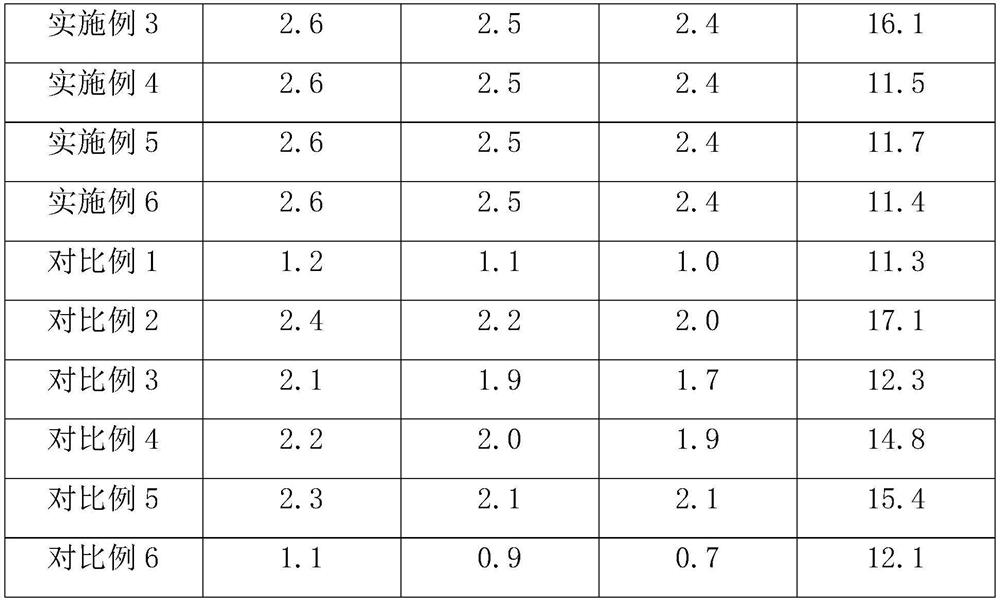

Examples

preparation example Construction

[0042] Preparation example of polyvinyl acetate emulsion

[0043] The polyvinyl alcohol in the following preparation examples was purchased from Shanghai Huihu Industrial Co., Ltd.; vinyl acetate was purchased from Jinan Mingwei Chemical Co., Ltd., with a density of 0.93 (g / cm 3 ); dibutyl phthalate was purchased from Xi'an Tianmao Chemical Co., Ltd.; butyl acrylate was purchased from Jinan Mingwei Chemical Co., Ltd.

preparation example 1

[0044] Preparation example 1: polyvinyl acetate emulsion is prepared by the following method:

[0045] S11. Weigh 60 kg of deionized water, 6 kg of polyvinyl alcohol, 30 kg of vinyl acetate, 0.26 kg of ammonium persulfate, 0.035 kg of dibutyl phthalate, 6 kg of butyl acrylate, and 0.06 kg of sodium bicarbonate;

[0046] S12. Put deionized water and polyvinyl alcohol in a reaction kettle, stir for 8 minutes at 90°C and 500 r / min, then add dibutyl phthalate and sodium bicarbonate and continue stirring for 5 minutes to obtain a stirred liquid ;

[0047] S13. Add ammonium persulfate, vinyl acetate, and butyl acrylate dropwise at a rate of 10 drops / min to the stirred liquid prepared in S12, and stir at a rate of 500 r / min for 15 min to prepare a polyvinyl acetate emulsion.

preparation example 2

[0048] Preparation example 2: polyvinyl acetate emulsion is prepared by the following method:

[0049] S11. Weigh 55 kg of deionized water, 4 kg of polyvinyl alcohol, 25 kg of vinyl acetate, 0.1 kg of ammonium persulfate, 0.02 kg of dibutyl phthalate, 4 kg of butyl acrylate, and 0.05 kg of sodium bicarbonate;

[0050] S12. Put deionized water and polyvinyl alcohol in a reaction kettle, stir for 8 minutes at 90°C and 500 r / min, then add dibutyl phthalate and sodium bicarbonate and continue stirring for 5 minutes to obtain a stirred liquid ;

[0051] S13. Add ammonium persulfate, vinyl acetate, and butyl acrylate dropwise at a rate of 10 drops / min to the stirred liquid prepared in S12, and stir at a rate of 500 r / min for 15 min to prepare a polyvinyl acetate emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com