Fluoride-free waterproof and oil-proof agent and preparation method thereof

A fluorine-free waterproof and oil-repellent technology, applied in the field of waterproof and oil-repellent, can solve the problems of human health impact, no waterproof and oil-repellent, difficult to decompose, etc., to achieve no impact on human health, good hydrophobic and oil-repellent performance, Effect without high temperature treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

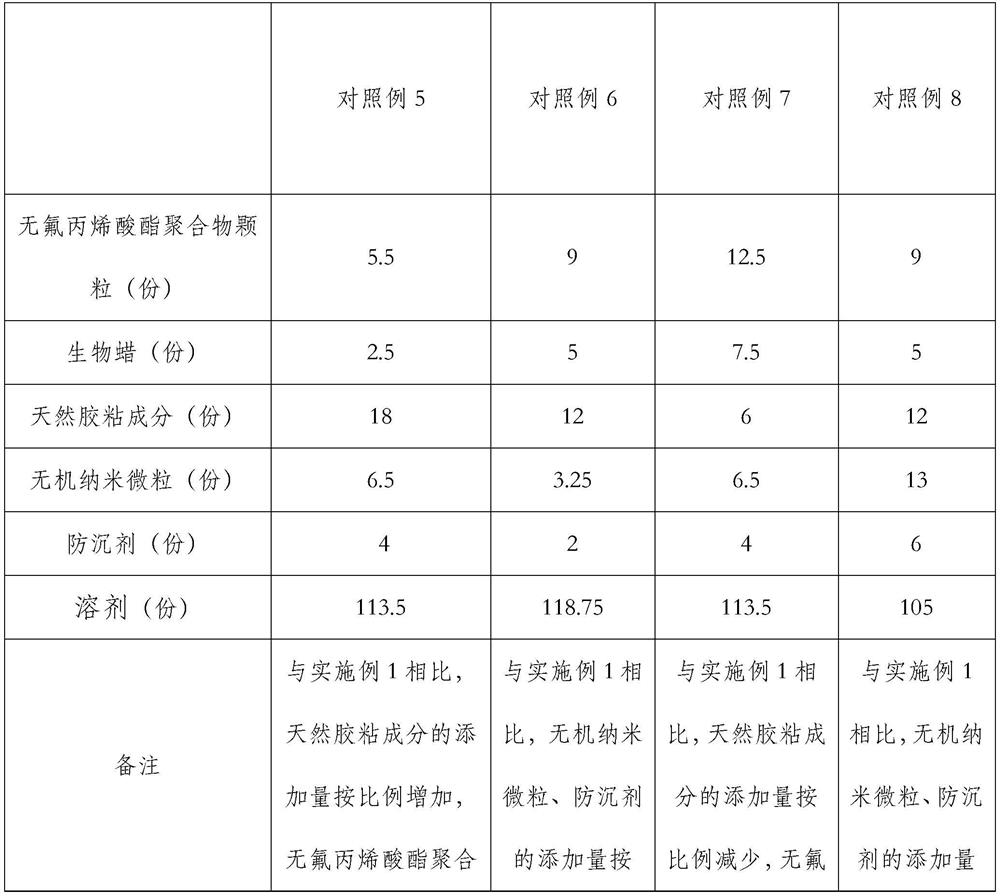

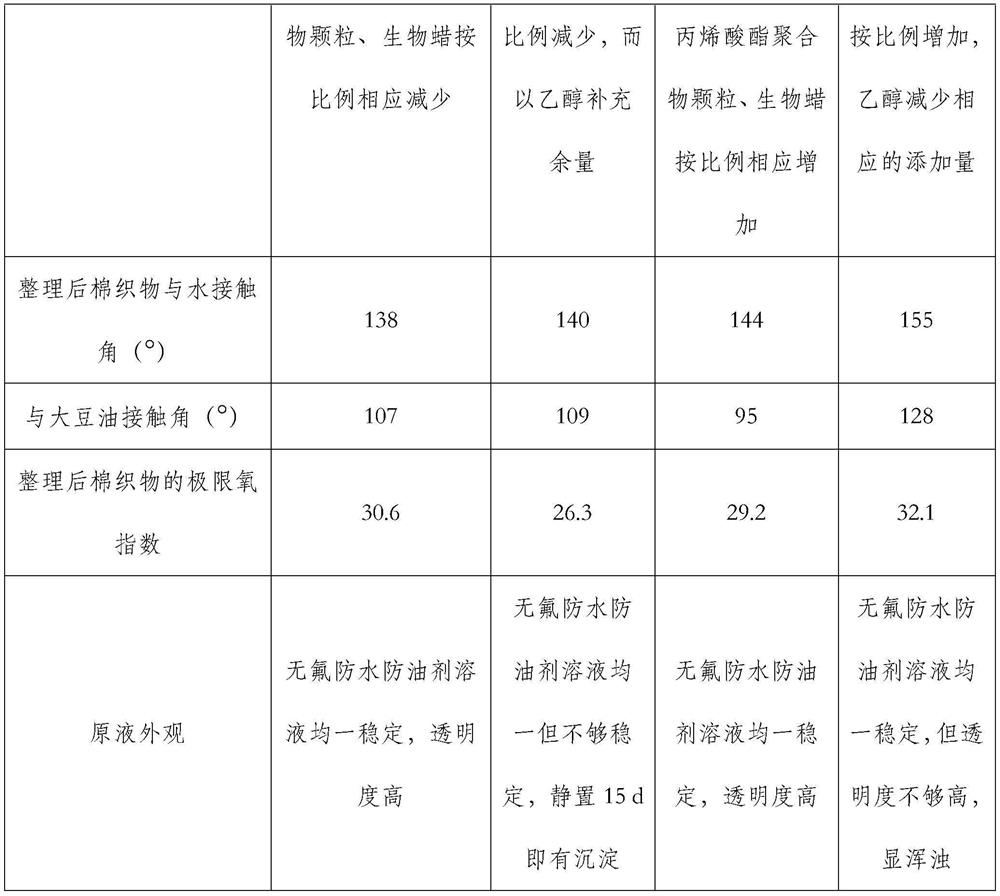

Examples

Embodiment 1

[0032](1) Add 16 parts of methyl methacrylate, 16 parts of butyl acrylate, and 13 parts of isoamyl acrylate to a dry reaction kettle with a stirring device, a thermometer and a condenser tube, then add 12 parts of isopentane, 8 parts of Cyclohexane, 14 parts of α-pinene, 16 parts of D-limonene, 0.7 part of tert-amyl peroxybenzoate, continuously stirred at a speed of 150 rpm under the protection of nitrogen, condensed under reflux and heated to 90 ° C, after 1 h Cool to 55°C, adjust the pH to alkaline with sodium bicarbonate; add 135 parts of water, and carry out ultrasonic dispersion for 15 minutes to emulsify; continue to add 24 parts of stearyl acrylate, 1 part of tea saponin, and 1.5 parts of cascara Glycolipid, after reacting at 55°C for 1 hour, slowly add an aqueous solution containing 2% potassium persulfate dropwise and rapidly raise the temperature to 90°C, after 2.5 hours of dropwise addition, the reaction ends, and cool to room temperature to obtain a fluorine-free ac...

Embodiment 2

[0038] (1) Add 16 parts of methyl methacrylate, 16 parts of butyl acrylate, and 13 parts of isoamyl acrylate to a dry reaction kettle with a stirring device, a thermometer and a condenser tube, then add 12 parts of isopentane, 8 parts of Cyclohexane, 14 parts of α-pinene, 16 parts of D-limonene, 0.7 part of tert-amyl peroxybenzoate, continuously stirred at a speed of 150 rpm under the protection of nitrogen, condensed under reflux and heated to 90 ° C, after 1 h Cool to 55°C, adjust the pH to alkaline with sodium bicarbonate; add 135 parts of water, and carry out ultrasonic dispersion for 15 minutes to emulsify; continue to add 24 parts of stearyl acrylate, 1 part of tea saponin, and 1.5 parts of cascara Glycolipid, after reacting at 55°C for 1 hour, slowly add an aqueous solution containing 2% potassium persulfate dropwise and rapidly raise the temperature to 90°C, after 2.5 hours of dropwise addition, the reaction ends, and cool to room temperature to obtain a fluorine-free a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com