Tackifying additive and application thereof in woodworking glue

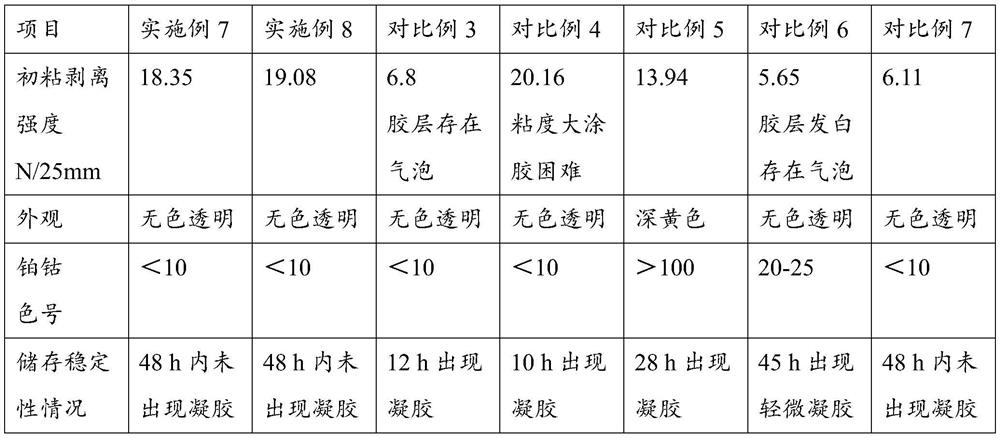

A technology of additives and end-capping agents, which is used in the field of tackifying additives and its application in woodworking glue, which can solve the problems of yellowish color, difficulty in dissolving, and looseness of adhesives, and improve positioning speed and initial adhesion. , The preparation method is simple, the effect of good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In one embodiment of the present invention, the present invention provides a preparation method of the above-mentioned thickening additive, and its preparation method is as follows: use aromatic dibasic acid, aliphatic dibasic acid, linear small molecule dibasic alcohol, alicyclic It is prepared by reacting catalyzed by inorganic acid esters and 4-dimethylaminopyridine composite catalysts using family dihydric alcohols and aromatic dihydric alcohols as raw materials.

[0034] In a specific embodiment, the preparation method is:

[0035] Weigh aromatic dibasic acids, fatty acid dibasic acids, aliphatic dibasic alcohols, alicyclic dibasic alcohols and aromatic dibasic alcohols in a certain proportion and add them into the reactor, and raise the temperature to 200-230°C under the protection of nitrogen to react 4- 6h, add inorganic acid esters and 4-dimethylaminopyridine composite catalyst catalyst, and then react under reduced pressure to remove the low-boiling reaction f...

Embodiment 1

[0046] Prepare the tackifying additive as follows:

[0047] Weigh 830.65g of terephthalic acid, 1038.31g of isophthalic acid, 182.7g of adipic acid, 315.42g of 1,4-butanediol, 793.1g of 1,4-cyclohexanedimethanol and 138.16g of terephthalic acid Put it into the reactor, raise the temperature to 180°C under the protection of nitrogen, react at constant temperature for 2h, then raise the temperature to 220°C for 5h, add catalyst isopropyl zirconate 0.18g and 4-dimethylaminopyridine 0.02g, catalyze the reaction for 1h, then pump Vacuum to -0.095Mpa to react under reduced pressure to remove the low-boiling reaction for 4 hours, and obtain a carboxyl-terminated intermediate product with a test acid value of 37.4 mg KOH / g, add 514.71 g of n-octadecyl alcohol as a capping agent, and react at 220 ° C for 4 hours , track the acid value of the system, if the acid value is less than 0.05mg KOH / g, vacuumize and depressurize the reaction for 2 hours. Cool down to 140°C and pour the obtained...

Embodiment 2

[0049] Prepare the tackifying additive as follows:

[0050] Weigh 770.84g of terephthalic acid, 965.22g of isophthalic acid, 80.39g of adipic acid, 114.15g of 1,3-propanediol, 1009.4g of 1,4-cyclohexanedimethanol and hydroquinone bishydroxyethyl Add 297.3g of ether into the reactor, raise the temperature to 180°C under the protection of nitrogen, react at constant temperature for 2h, then raise the temperature to 225°C for 4h, add catalyst tetraisopropyl titanate 0.21g and 4-dimethylaminopyridine 0.05g, catalyze the reaction 1.5h, then evacuate to -0.095Mpa depressurization reaction to remove the low boiling reaction for 5h, obtain the intermediate product end-capped by carboxyl group, test acid value is 23.67mg KOH / g, add blocking agent isooctyl alcohol 156.11g, at 225 React at ℃ for 4 hours, track the acid value of the system, if the acid value is less than 0.05mg KOH / g, then vacuumize and decompress and react for 2 hours. Cool down to 140℃ and pour the obtained material int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com