Flame-retardant reinforced wood and preparation method thereof

A technology of wood and flame retardant, which is applied in the direction of wood treatment, impregnated wood, wood impregnation, etc., can solve the problems of poor anti-loss ability, increased steps and costs, and large VOC release, so as to achieve enhanced toughness and anti-loss, good Effect of Dimensional Stability and Enhancement of Flame Retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

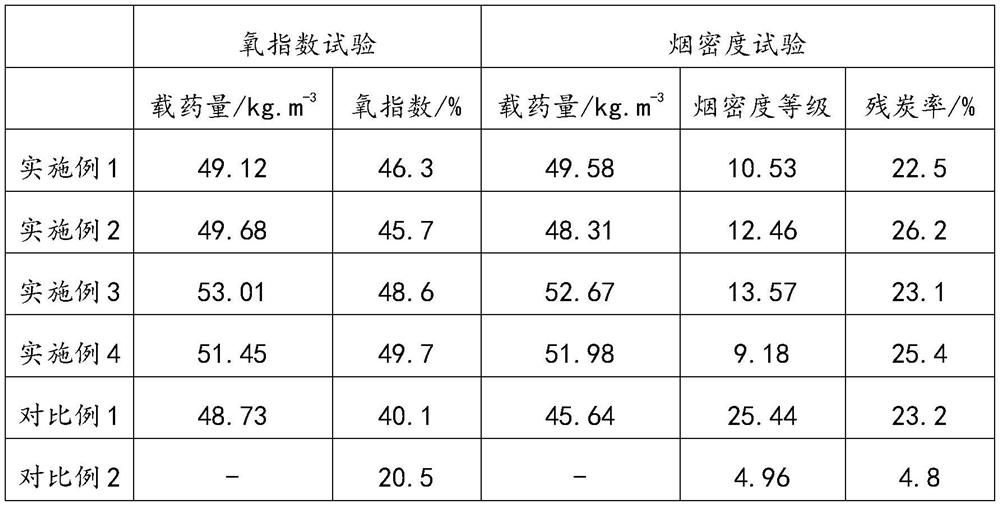

Examples

Embodiment 1

[0035] A flame-retardant reinforced wood, which is made by soaking the wood in a wood modifier and vacuum impregnating treatment under vacuum pressure, controlling the vacuum degree to -0.3-0.8MPa, and the pressure to 0.5-1.5MPa. The time is 1.5-3 hours to obtain vacuum-impregnated wood; the vacuum-impregnated wood is dried to obtain flame-retardant reinforced wood.

[0036]The above-mentioned wood modifier is composed of the following raw materials in parts by weight: 5 parts of triazole compounds, 20 parts of hydroxyethyl methacrylate, 0.8 parts of catalyst n-butyllithium, 20 parts of ammonium dihydrogen phosphate, nonionic surface active 20 parts of agent, 3 parts of silicon dioxide powder, 3 parts of silane coupling agent, 6 parts of flame retardant, 90 parts of polyethylene glycol and 900 parts of water, and its preparation method comprises the following specific steps:

[0037] (1) Divide polyethylene glycol into three equal parts and add in two times;

[0038] (2) Add ...

Embodiment 2

[0044] A flame-retardant reinforced wood, which is made by soaking the wood in a wood modifier and vacuum impregnating treatment under vacuum pressure, controlling the vacuum degree to -0.3-0.8MPa, and the pressure to 0.5-1.5MPa. The time is 1.5-3 hours to obtain vacuum-impregnated wood; the vacuum-impregnated wood is dried to obtain flame-retardant reinforced wood.

[0045] The above-mentioned wood modifier is composed of the following raw materials in parts by weight: 10 parts of triazole compounds, 10 parts of hydroxyethyl methacrylate, 0.5 parts of catalyst n-butyllithium, 10 parts of ammonium dihydrogen phosphate, nonionic surface active 40 parts of agent, 5 parts of silicon dioxide powder, 5 parts of silane coupling agent, 2 parts of flame retardant, 90 parts of polyethylene glycol and 400 parts of water, its preparation method is the same as in Example 1, and the specific steps refer to Example 1.

[0046] In this example, the triazole compounds are 5 parts of 5-methyl...

Embodiment 3

[0048] A flame-retardant reinforced wood, which is made by soaking the wood in a wood modifier and vacuum impregnating treatment under vacuum pressure, controlling the vacuum degree to -0.3-0.8MPa, and the pressure to 0.5-1.5MPa. The time is 1.5-3 hours to obtain vacuum-impregnated wood; the vacuum-impregnated wood is dried to obtain flame-retardant reinforced wood.

[0049] The above-mentioned wood modifier is composed of the following raw materials in parts by weight: 6 parts of triazole compounds, 18 parts of hydroxyethyl methacrylate, 0.6 parts of catalyst n-butyllithium, 15 parts of ammonium dihydrogen phosphate, nonionic surface active 30 parts of agent, 4 parts of silicon dioxide powder, 4 parts of silane coupling agent, 3 parts of flame retardant, 90 parts of polyethylene glycol and 600 parts of water, the preparation method is the same as in Example 1, and the specific steps refer to Example 1.

[0050] In this example, the triazole compound is 3,5-diisopropyl-1,2,4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com