Synthetic method of cetrorelix

A technology of cetrorelix and a synthesis method, applied in the field of peptide synthesis, can solve the problems of difficult fragment synthesis method, strong corrosiveness of acetic anhydride, limited access, etc., and achieves reduction of purification times, weak corrosion, and purification loss. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

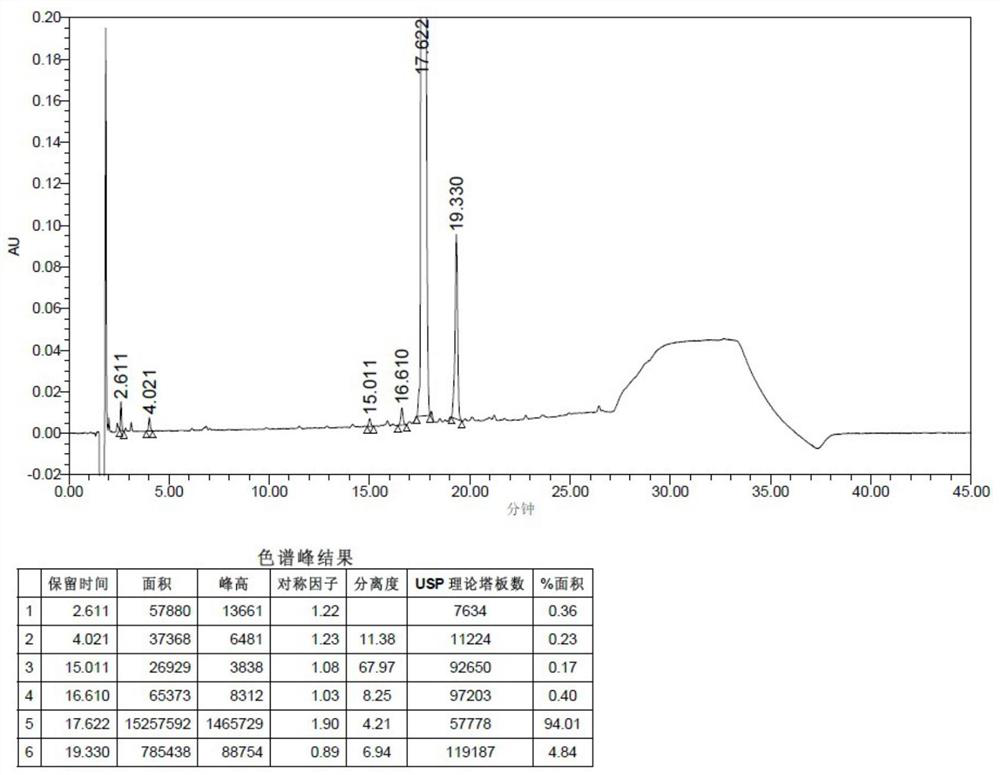

Image

Examples

Embodiment 1

[0030] The synthetic method of Cetrorelix of the present invention, the detailed steps of this synthetic method are as follows:

[0031] (1) Preparation of Fmoc-D-Ala-resin:

[0032] Soak and swell 10g of Knorr-2-Cl-Resin resin with 70ml of dichloromethane DCM for 30min to fully swell the Knorr-2-Cl-Resin resin, drain it after swelling, then add 50ml of deprotection reagent, at 25±5℃ The deprotection reaction was carried out at 25±5°C for 10 minutes, and after the reaction, it was drained, and then 50ml of deprotection reagent was added again, and it was reacted at 25±5°C for 10 minutes, and after the reaction, it was drained. Wash twice with DMF and once with DCM, each time using 50ml of detergent, drain after washing, then add 3.7g of Fmoc-D-Ala-OH (the resin refers to N-fluorenylmethoxycarbonyl-D-propane amino acid) and condensing agent, reacted at 25±5°C for 2h, and drained after the reaction, the obtained resin was washed 3 times with DMF, each time using 50ml of deterge...

Embodiment 2

[0059] The synthetic method of Cetrorelix of the present invention, the detailed steps of this synthetic method are as follows:

[0060] (1) Preparation of Fmoc-D-Ala-resin:

[0061] Soak and swell 10g of Knorr-2-Cl-Resin resin with 70ml of DCM for 30min to fully swell the Knorr-2-Cl-Resin resin, drain it after swelling, then add 50ml of deprotection reagent, and deprotect at 25±5℃ React for 10 minutes, evacuate after reaction, add 50ml of deprotection reagent again after pumping dry, react at 25±5°C for 10 minutes, dry after reaction, wash the product twice with DMF and once with DCM, each time with washing 50ml of solvent, drained after washing, then added 3.74g of Fmoc-D-Ala-OH and condensing agent, reacted at 25±5°C for 1h, and drained after reaction, the obtained resin was washed 3 times with DMF, each time with Detergent 50ml, after washing, drain to obtain Fmoc-D-Ala-resin;

[0062] The deprotection reagent used in this step is the N,N-dimethylformamide solution with ...

Embodiment 3

[0088] The synthetic method of Cetrorelix of the present invention, the detailed steps of this synthetic method are as follows:

[0089] (1) Preparation of Fmoc-D-Ala-resin:

[0090] Soak and swell 10g of Knorr-2-Cl-Resin resin with 70ml of DCM for 30min to fully swell the Knorr-2-Cl-Resin resin, drain it after swelling, then add 50ml of deprotection reagent, and deprotect at 25±5℃ React for 10 minutes, drain after reaction, add 50ml of deprotection reagent again after draining, react at 25±5°C for 10 minutes, and drain after reaction. The obtained product is washed twice with DMF and once with DCM, each time with Detergent 50ml, drained after washing, then added 3.74g Fmoc-D-Ala-OH and condensing agent, reacted at 25±5°C for 1h, and drained after reaction, the obtained resin was washed 3 times with DMF, each time Use 50ml of detergent, dry after washing to obtain Fmoc-D-Ala-resin;

[0091] The deprotection reagent used in this step is the N,N-dimethylformamide solution with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com