Bacillus subtilis strain sh21 producing chitinase, method for producing chitinase, microbial preparation and application

A chitinase and strain technology, applied in the field of microorganisms, can solve the problems of large differences in chitinase enzyme yield and enzyme activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] LB medium formula: 10 g of peptone, g of yeast extract powder, 10 g of NaCl, (solid medium plus 15 g of agar) 1000 mL of distilled water, pH 7.0. Seed liquid medium: same as LB medium. Example 1: Breeding and isolation of Bacillus subtilis SH21 and detection of chitinase activity

[0046] The purpose of this example is to separate and purify Bacillus subtilis from soybean paste, which is used to screen strains with high chitinase activity.

[0047] The specific experimental method is as follows:

[0048](1) Grind the soybean paste collected from the natural fermentation of farmers in Daliangshan, Sichuan, apply a small amount of paste powder with an inoculation ring and spread it on the chitinase-producing screening medium plate, cultivate at 30°C for 1-2 days, and observe the growth of the colony. , pick colonies that grow well, have large decomposition circles and are transparent.

[0049] The strains were inoculated into LB solid medium and purified to a single co...

Embodiment 2

[0061] Example 2 Production of chitinase by using Bacillus subtilis strain SH21--optimized fermentation conditions

[0062] This example optimizes the liquid fermentation conditions of Bacillus subtilis SH21, including single factor optimization test and response surface test. The specific test method is shown as follows:

[0063] Bacillus subtilis SH21 was inoculated into the seed medium, cultured at 30°C with shaking at 180 r / min for 12 hours, and then transferred to the fermentation medium, and the initial culture conditions were set as follows: the fermentation temperature was 37°C, and the initial pH value was 7 , the inoculum amount was 2%, and the fermentation time was 24h.

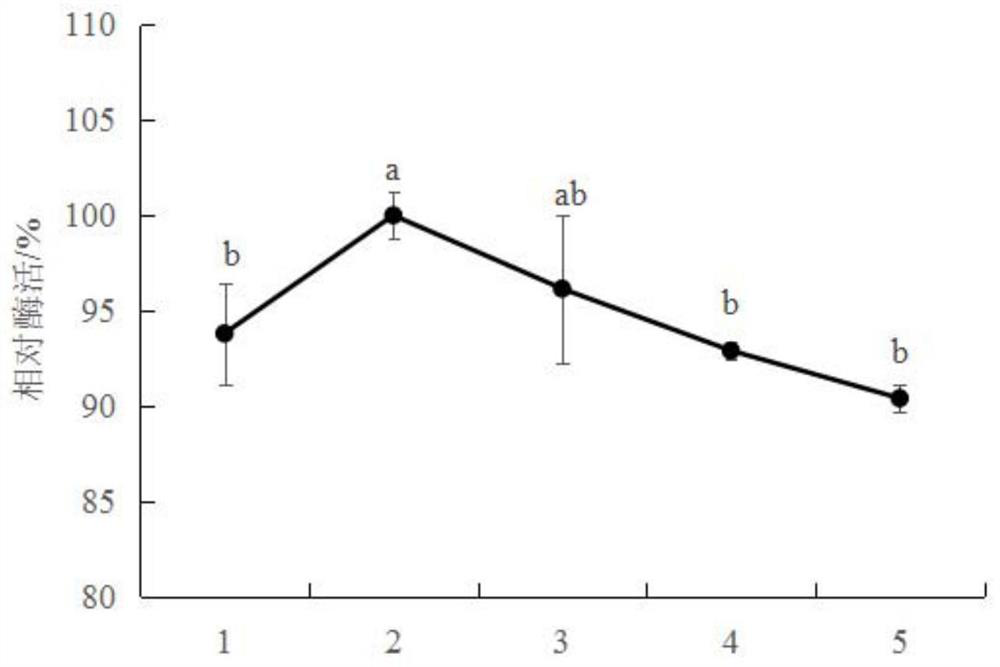

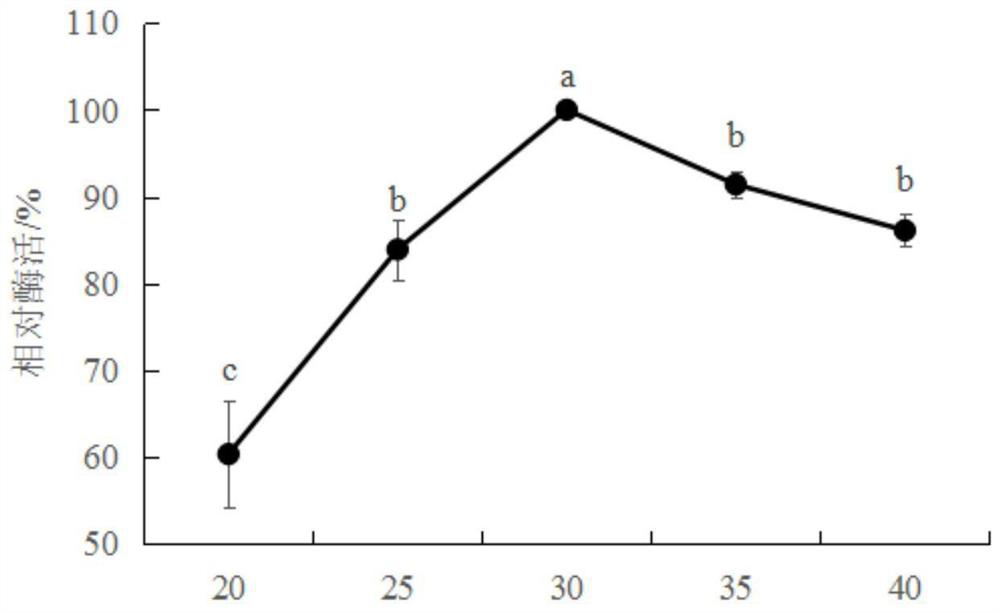

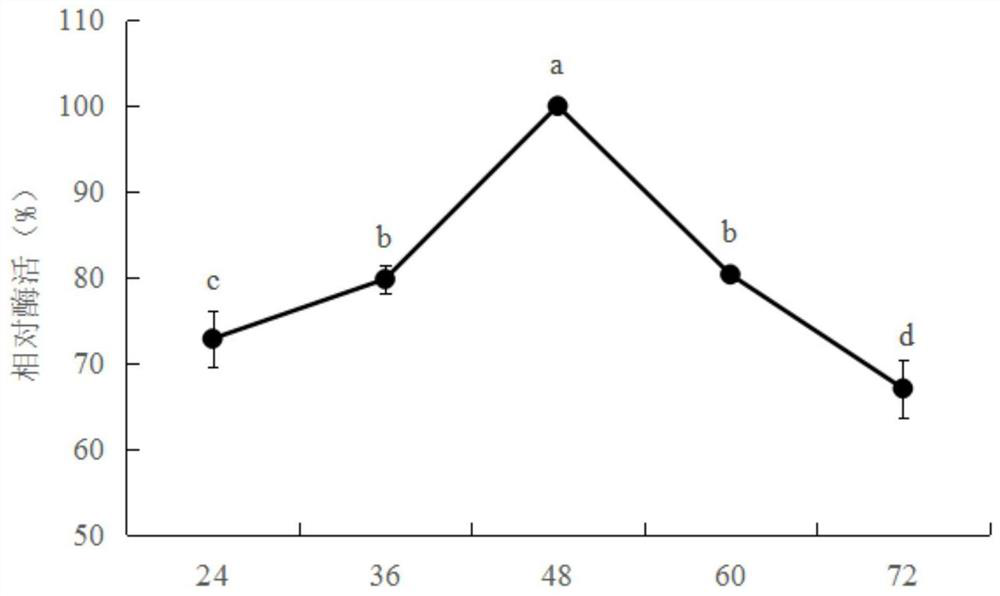

[0064] The main influencing factors of fermentation culture (inoculation amount, fermentation temperature, fermentation time, initial pH value) were single-factor optimization test, and the enzyme activity of each fermentation broth under different conditions was measured (see Example 1 for the me...

Embodiment 3

[0073] Example 3: Purification and Characterization of Chitinase from Bacillus subtilis Fermentation Products

[0074] This example is the purification and characteristic analysis of the aforementioned Bacillus subtilis fermentation product chitinase. The specific method is shown as:

[0075] The enzyme was precipitated with 75% ammonium sulfate, dialyzed against 0.02M Tris-HCl buffer, applied to a Superdex 75PG column (1.6 x 64.6 cm) pre-equilibrated with the same buffer, and eluted , the flow rate is 1mL / min. The elution peaks were collected, the enzyme activity and protein concentration in each fraction were determined separately, and the fraction containing the most active enzyme was collected, concentrated by ultrafiltration, and then loaded onto a SP HPR column pre-equilibrated with PBS (pH 6.5) , and then eluted with the same buffer containing 1 mol NaCl at a flow rate of 2.5 mL / min. Fractions with a single peak of fibrinolytic activity were pooled, concentrated and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com