Method for recovering heavy metal from copper-containing sludge

A technology of copper sludge and heavy metals, applied in the direction of improving process efficiency, etc., can solve the problems of copper-containing sludge waste and other problems, and achieve the effect of efficient resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

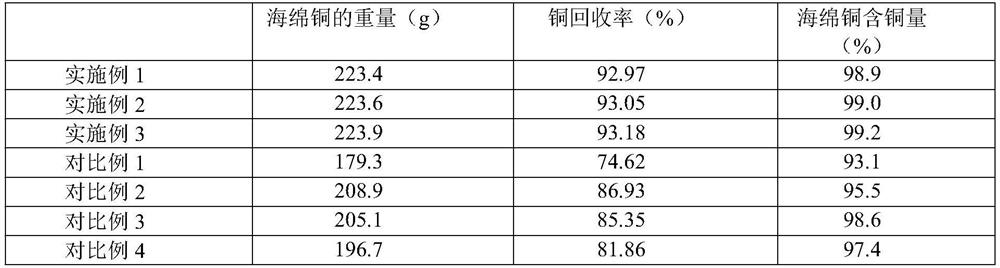

Examples

Embodiment 1

[0036] A method for recovering heavy metals from copper-containing sludge, the specific steps are as follows:

[0037] (1) First mix soybean rhizobia, Pseudomonas cepacia and Lactobacillus according to a mass ratio of 1:0.3:0.8 to make a mixed bacterial powder, then inoculate the mixed bacterial powder into copper-containing sludge, and ferment to obtain a fermentation product;

[0038] (2) Then add the first part of concentrated hydrochloric acid to the fermentation product, add dropwise phosphoric acid aqueous solution while stirring, add the second part of concentrated hydrochloric acid after the dropwise addition, stir and react, centrifuge to obtain the supernatant and precipitation I, and enter the step ( 3) and (4);

[0039] (3) Immerse the excess iron wire in the supernatant, stir and react, and collect the precipitate II by centrifugation;

[0040] (4) Finally, add the precipitate I to the concentrated hydrochloric acid, stir the reaction, collect the precipitate III...

Embodiment 2

[0056] A method for recovering heavy metals from copper-containing sludge, the specific steps are as follows:

[0057] (1) First mix soybean rhizobia, Pseudomonas cepacia and Lactobacillus according to a mass ratio of 1:0.5:0.5 to make a mixed bacterial powder, then inoculate the mixed bacterial powder into copper-containing sludge, and ferment to obtain a fermentation product;

[0058] (2) Then add the first part of concentrated hydrochloric acid to the fermentation product, add dropwise phosphoric acid aqueous solution while stirring, add the second part of concentrated hydrochloric acid after the dropwise addition, stir and react, centrifuge to obtain the supernatant and precipitation I, and enter the step ( 3) and (4);

[0059] (3) Immerse the excess iron wire in the supernatant, stir and react, and collect the precipitate II by centrifugation;

[0060] (4) Finally, add the precipitate I to the concentrated hydrochloric acid, stir the reaction, collect the precipitate III...

Embodiment 3

[0076] A method for recovering heavy metals from copper-containing sludge, the specific steps are as follows:

[0077] (1) First mix soybean rhizobia, Pseudomonas cepacia and Lactobacillus according to a mass ratio of 1:0.4:0.7 to make a mixed bacterial powder, then inoculate the mixed bacterial powder into copper-containing sludge, and ferment to obtain a fermentation product;

[0078] (2) Then add the first part of concentrated hydrochloric acid to the fermentation product, add dropwise phosphoric acid aqueous solution while stirring, add the second part of concentrated hydrochloric acid after the dropwise addition, stir and react, centrifuge to obtain the supernatant and precipitation I, and enter the step ( 3) and (4);

[0079] (3) Immerse the excess iron wire in the supernatant, stir and react, and collect the precipitate II by centrifugation;

[0080] (4) Finally, add the precipitate I to the concentrated hydrochloric acid, stir the reaction, collect the precipitate III...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com