Preparation technology of moxifloxacin hydrochloride sodium chloride injection

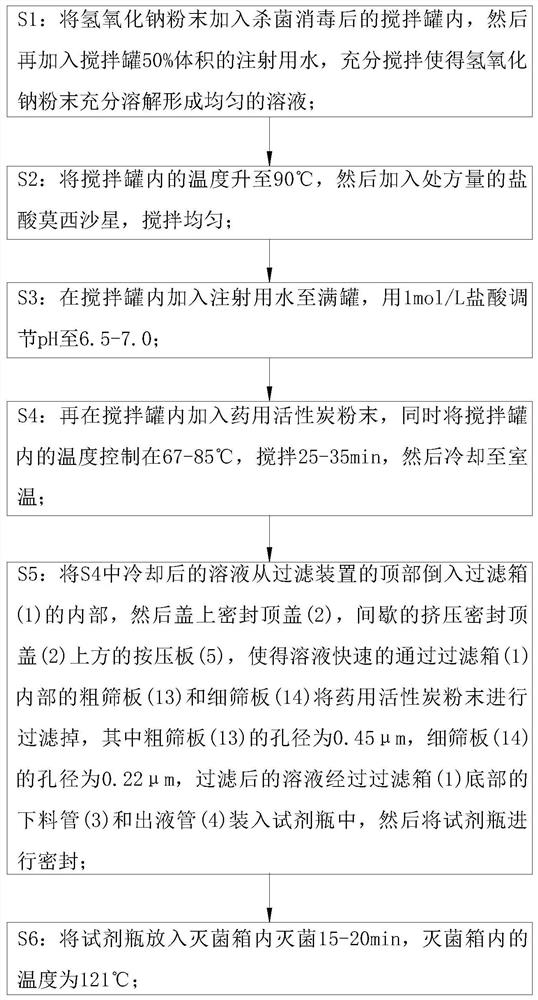

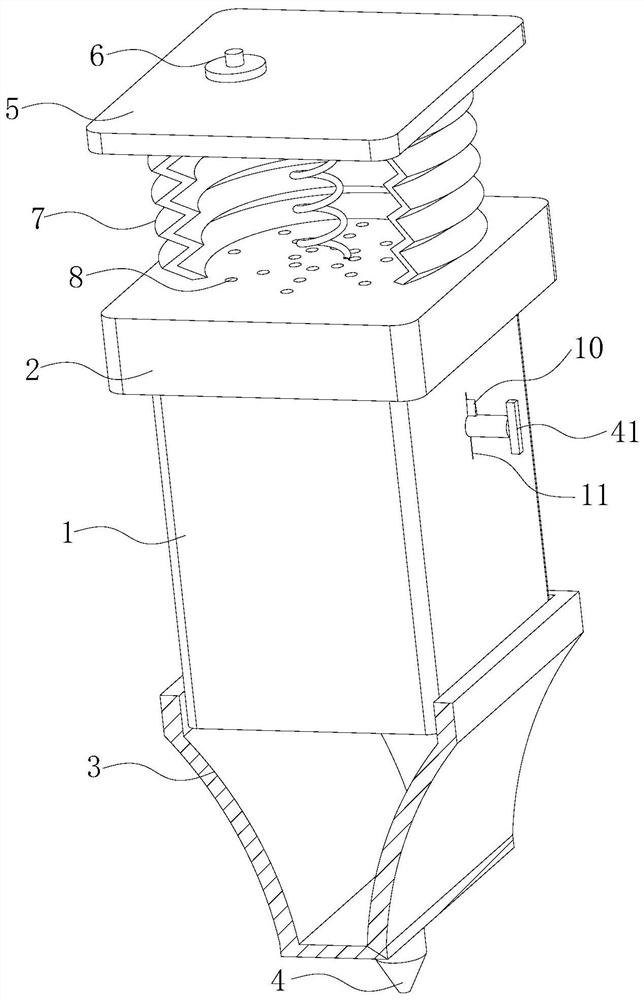

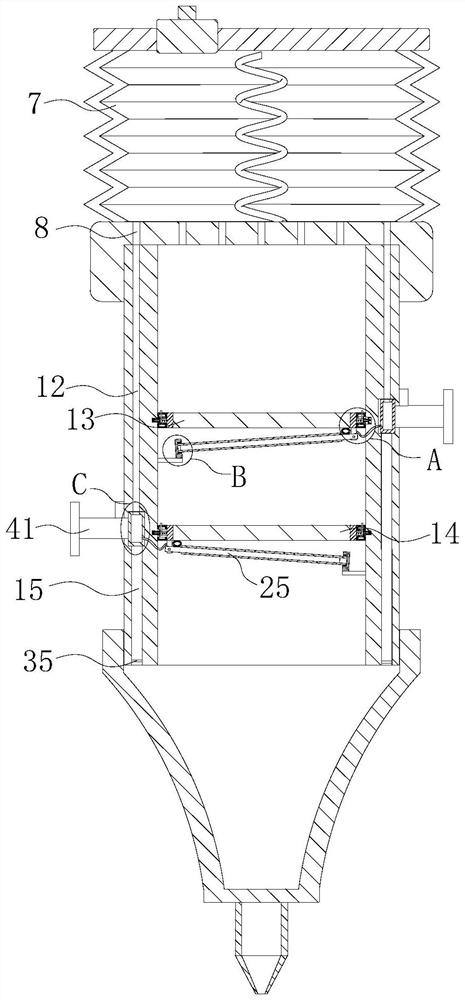

A technology for sodium chloride injection and moxifloxacin hydrochloride, which is applied in medical preparations containing active ingredients, chemical instruments and methods, and devices for making medicines into special physical or taking forms, etc., which can solve the problem of screen cleaning. Inconvenience, residual activated carbon particles, low solution yield and other problems, to achieve the effect of saving filtration time, efficient cleaning, and improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] As an embodiment of the present invention, the clamping mechanism includes a sliding groove 19, an insertion rod 24, a cylinder 36 and a push plate 37; one end of the cylinder 36 is fixedly installed on the outer wall of the fixed frame 16; A push plate 37 is provided inside the cylindrical barrel 36; the side of the push plate 37 close to the fixed frame 16 is fixedly connected with the outer wall of the fixed frame 16 through a spring, and the side of the push plate 37 far away from the fixed frame 16 is connected with the insertion rod. One end of 24 is fixedly connected; The free end of described insertion rod 24 is inserted in the draw-in groove 22 of filter case 1 inner wall; The top of described push plate 37 is connected with the bottom end of push rod 18; The bottom end of described push rod 18 Located in the sliding groove 19 on the top edge of the cylinder 36; the top end of the push rod 18 stretches out from the top edge of the cylinder 36; during work, when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com