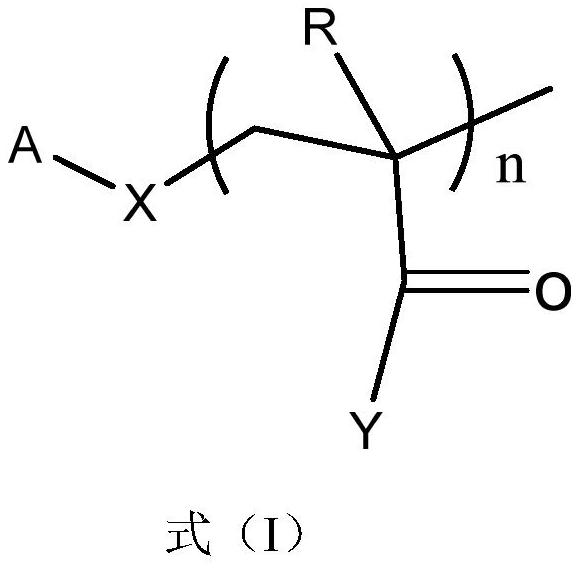

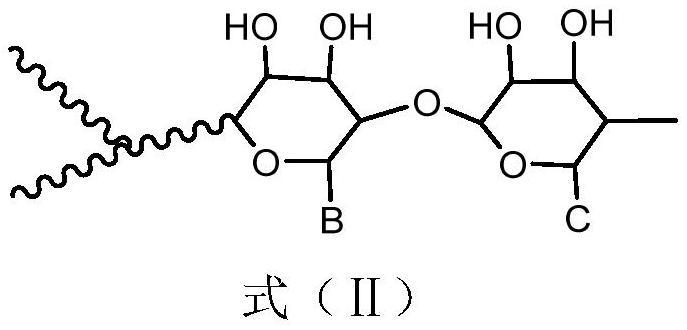

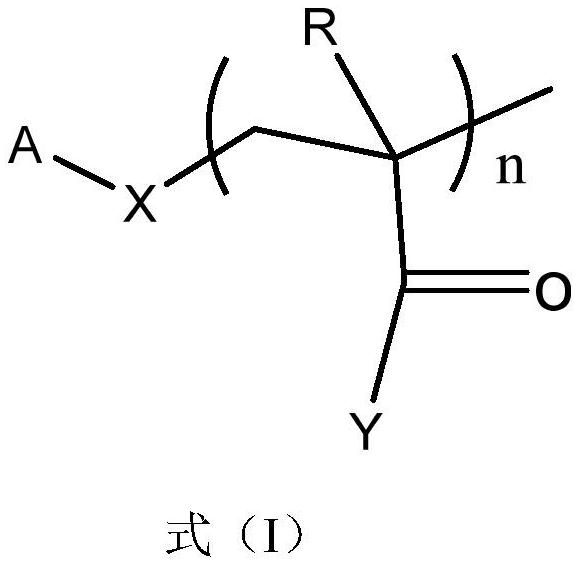

A kind of biomass modified polymer binder, its preparation method and its application in silicon-based electrode lithium-ion battery

A polymer and binder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as lack of practical application ability, achieve stable structure, good electrochemical performance, and overcome the effect of volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of silicon-based electrode lithium ion battery binder and electrode coating.

[0027] Add 100g of water and 11g of cornstarch into a 250ml three-neck flask, mechanically stir at 89°C for 10min, then add 0.275g of ammonium persulfate and continue stirring for 30min, then add 0.044g of ferrous sulfate, adjust the temperature to 85°C and stir well After 10 minutes, 2.25 g of hydrogen peroxide with a mass fraction of 30% was added. Then, 10 g of acrylic acid and 24 g of butyl acrylate were gradually added dropwise, and the dropwise addition was completed within 1 hour. After the dropwise addition, the reaction was continued for 2 hours to obtain the water-based polymer product P1.

[0028] Add silicon powder: super P: P1: sodium alginate = 6:2:1:1 into the mortar by grinding and blending, and use the preparation device to coat the resulting slurry on the copper foil, and the copper foil Dry in an oven at 60°C for 24 hours, then dry in an oven at 180°C...

Embodiment 2

[0029] Example 2 Preparation of silicon-based electrode lithium ion battery binder and electrode coating.

[0030] Add 40g of water and 3.6g of cornstarch into a 150ml three-neck flask, mechanically stir at 89°C for 10min, then add 0.007g of starch hydrolytic enzyme and continue stirring for 5min, then add 0.014g of ferrous sulfate, adjust the temperature to 85°C and stir thoroughly Mix for 10 minutes, then add 0.75g of 30% hydrogen peroxide. Then 7g of acrylic acid + 10g of water mixed solution was added dropwise, and the dropwise addition was completed within 30 minutes. After the dropwise addition, the reaction was continued for 2 hours to obtain the water-based polymer product P1.

[0031] Add silicon powder: super P: P1: sodium alginate = 6:2:1:1 into the mortar by grinding and blending, and use the preparation device to coat the resulting slurry on the copper foil, and the copper foil Dry in an oven at 60°C for 24 hours, then dry in an oven at 170°C for 1.5 hours, and f...

Embodiment 3

[0032] Example 3 Preparation of silicon-based electrode lithium ion battery binder and electrode coating.

[0033] Add 40g of water and 7g of cornstarch into a 150ml three-necked flask, mechanically stir at 89°C for 10min, then add 0.014g of starch hydrolytic enzyme and continue stirring for 5min, then add 0.02g of ferrous sulfate, adjust the temperature to 85°C and stir well After 10 minutes, 0.25 g of hydrogen peroxide with a mass fraction of 30% was added. Then 7g of acrylic acid + 10g of water + 0.75g of 30% hydrogen peroxide mixed solution was added dropwise, and the dropwise addition was completed within 40 minutes. After the dropwise addition, the reaction was continued for 2 hours to obtain the water-based polymer product P1.

[0034] Add silicon powder: super P: P1: sodium alginate = 6:2:1:1 into the mortar by grinding and blending, and use the preparation device to coat the resulting slurry on the copper foil, and the copper foil Dry in an oven at 60°C for 24 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com