Thermal insulation dry powder putty and its application method

A putty, dry powder technology, applied in covering/lining, construction, filling slurry, etc., can solve the problems of reducing indoor building area, increasing building load, increasing construction process, etc., to increase construction process, reduce building energy consumption, reduce The effect of building area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

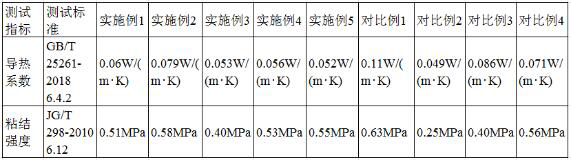

Examples

preparation example Construction

[0071] In one embodiment, the preparation method of the titanium dioxide-coated hollow ceramic microspheres comprises the following steps:

[0072] Weigh 5g of ceramic microbeads, put in 50mL of distilled water, drop in 10 drops of alanine glutamate, stir and disperse in a 500mL four-neck flask, adjust the pH of the system to 2.0 with hydrochloric acid solution, add an appropriate amount of urea, and then heat up At 70-80°C, add 10% tin tetrachloride solution, use the OH- generated by the hydrolysis of urea to precipitate the tin salt and evenly deposit it on the surface of the ceramic microbeads, then add TiCl 4 At the same time, an appropriate amount of urea was added to the solution, reacted at 70°C for 1h, continued to heat up to 80°C for another 2h, and then aged at 70°C for 1h. Filter the microbeads, roast at 300° C. to remove crystal water, and then roast at 900° C. for 30 minutes to obtain titanium dioxide-coated ceramic microbeads in rutile phase.

[0073] Add alumin...

Embodiment 1

[0123] This embodiment provides a thermal insulation dry powder putty and its preparation method and use method, the steps are as follows:

[0124] In terms of weight percentage, weigh 50% desulfurized gypsum, 3% redispersible latex powder, 10% titanium dioxide-coated hollow ceramic microspheres, 4% aluminum oxide powder, 6% mica powder, 26.1% heavy calcium, 0.1 % retarder, 0.5% water retaining agent, 0.3% water reducing agent.

[0125] Preparation method: Pour desulfurized gypsum, redispersible latex powder, aluminum oxide powder, mica powder, heavy calcium, retarder, water retaining agent and water reducer into mixing equipment and mix evenly, then pack to obtain component A . The titanium dioxide-coated hollow ceramic microspheres are individually packaged to obtain component B.

[0126] How to use: Weigh water, pour into component A, stir at 800rpm at high speed for 4 minutes, then let stand for 5 minutes, then add component B, stir at 200rpm at low speed for 2 minutes, ...

Embodiment 2

[0128] This embodiment provides a thermal insulation dry powder putty and its preparation method and use method, which are basically the same as in Embodiment 1, the only difference being that the amount of titanium dioxide-coated hollow ceramic microspheres and heavy calcium is different, and the steps are as follows:

[0129] In terms of weight percentage, weigh 50% desulfurized gypsum, 3% redispersible latex powder, 5% titanium dioxide-coated hollow ceramic microspheres, 4% aluminum oxide powder, 6% mica powder, 31.1% heavy calcium, 0.1 % retarder, 0.5% water retaining agent, 0.3% water reducing agent.

[0130] Preparation method: Pour desulfurized gypsum, redispersible latex powder, aluminum oxide powder, mica powder, heavy calcium, retarder, water retaining agent and water reducer into mixing equipment and mix evenly, then pack to obtain component A . The titanium dioxide-coated hollow ceramic microspheres are individually packaged to obtain component B.

[0131] How to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com