Chloromethane gas dehydration process in butyl rubber production process

A production process and butyl rubber technology, applied in the field of separation and purification, can solve the problems of high hygroscopicity, corrosion of equipment, and difficulty in recycling of triethylene glycol, so as to avoid high energy consumption and environmental pollution, reduce industrial costs, and shorten the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

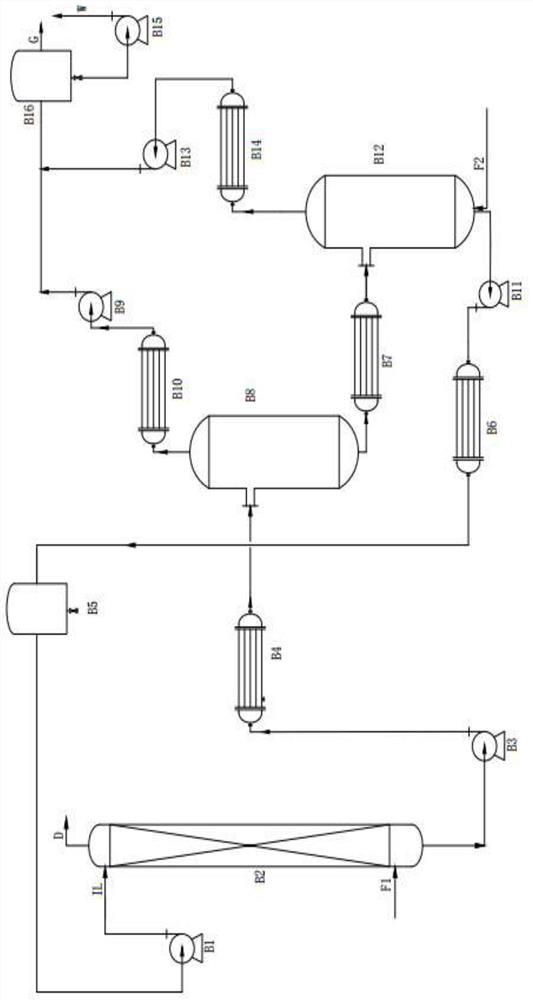

[0017] Such as figure 1 The absorption process is shown. The operating condition of absorption tower is: temperature 25 ℃, pressure absolute pressure 400kp, theoretical column number 6, come from the massfraction of one strand of industrial material (monochloromethane, isobutylene, water, hexane, isoprene of halogenation reaction is 94.66%, 4.72%, 0.3%, 0.2, 0.12) feed from the bottom of the absorption tower, the mass flow rate is controlled at 1000kg / h, ionic liquid [EMIM] + [BF 4 ] - (1-ethyl-3-methylimidazolium tetrafluoroboric acid) is added from the top of the absorption tower as an absorbent, and the mass flow rate is 535kg / h. The water in the material is removed, and the water-rich ionic liquid at the bottom of the absorption tower enters the first flash tank to remove most of the methyl chloride contained in it. The operating conditions of the first flash tank are: temperature 50 ° C, pressure 0.05 atm, Then enter the second flash tank to remove the water contained...

Embodiment 2

[0028] The absorption process is shown in the figure. The operating conditions of the absorption tower are: 25°C of temperature, 400kp of absolute pressure, 6 theoretical towers, a stream of industrial materials from the halogenation reaction (the mass fraction of monochloromethane, isobutylene, water, hexane, isoprene is 94.66 %, 4.72%, 0.3%, 0.2, 0.12) feed from the bottom of the absorption tower, mass flow control 1000kg / h, ionic liquid [EMIM] + [BF 4 ] - (1-ethyl-3-methylimidazolium tetrafluoroboric acid) is added from the top of the absorption tower as an absorbent, and the mass flow rate is 535kg / h. At this time, the water content of the tower top material is 50ppm, which shows that the use of ionic liquid dehydration technology can significantly dehydrate In addition to the water in the material, the water-rich ionic liquid at the bottom of the absorption tower enters the first flash tank to remove most of the methyl chloride contained in it. The operating conditions ...

Embodiment 3

[0036] The absorption process is shown in the figure. The operating conditions of the absorption tower are: temperature 25°C, absolute pressure 400kp, theoretical tower number 6, a stream of industrial materials from the halogenation reaction (the mass fraction of monochloromethane, isobutylene, water, hexane, isoprene is 94.66 %, 4.72%, 0.3%, 0.2, 0.12) feed from the bottom of the absorption tower, mass flow control 1000kg / h, ionic liquid [EMIM] + [BF4] - (1-Ethyl-3-methylimidazolium tetrafluoroboric acid) is added from the top of the absorption tower as an absorbent, and the mass flow rate is 535kg / h. At this time, the water content of the tower top material is 50ppm, which shows that the use of ionic liquid dehydration technology can significantly dehydrate In addition to the water in the material, the water-rich ionic liquid at the bottom of the absorption tower enters the first flash tank to remove most of the methyl chloride contained in it. The operating conditions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com