A kind of method for preparing carbon black

A technology of carbon black and carbon powder, which is applied in the treatment of dyed low-molecular organic compounds, fibrous fillers, etc., can solve the problems of consumption of non-renewable resources, high price of carbon black, high production cost, etc., to save non-renewable resources and improve adsorption Good effect on specific surface area, dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

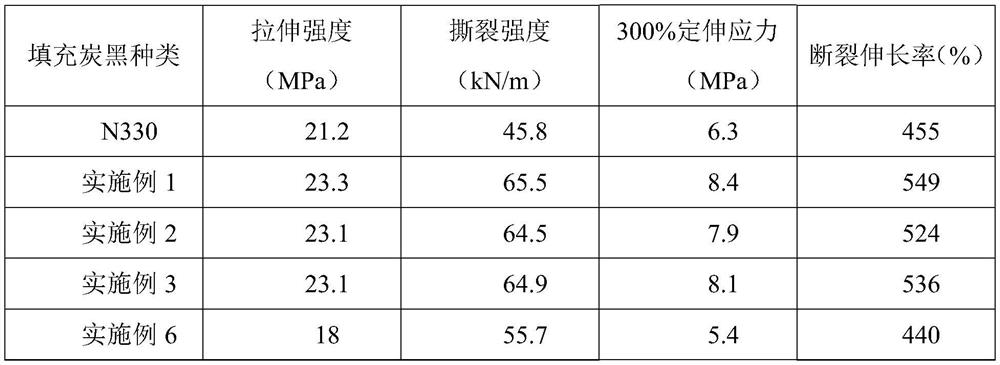

Embodiment example 1

[0050] Take 10kg of petroleum coke in the production process of a domestic factory, the main element content is (wt.%): C 90.18, H 3.83, S2.25, N 1.27, O 2.31, crushed to -200 mesh, accounting for 90%, add 200L of 8mol / A mixed solution of L nitric acid and 2mol / L hydrogen peroxide was leached for 10 hours at a leaching temperature of 80°C and a stirring rate of 200r / min. Then filter and wash with 2mol / L ammonia water, adjust the pH value to 7.9, and dry to obtain carbon powder.

[0051] Put the obtained carbon powder into a muffle furnace for calcination, the protective atmosphere is nitrogen, the temperature is 800°C, and the time is 3h. Put the calcined carbon powder into a high-speed kneader, and then add 1% of the mass of the carbon powder The titanate modifier was started to knead in a high-speed kneader, the kneading temperature was 160°C, and the kneading time was 75 minutes, and then transferred to an ultrafine mill for ultrafine pulverization to obtain coke carbon bl...

Embodiment example 2

[0054] Take 20kg of petroleum coke in the production process of a domestic factory, the main element content is (wt.%): C 84.36, H 3.393, S 6.602, N 1.500, O 4.147, crushed to -200 mesh, accounting for 90%, add 300L of 6mol / L The mixed solution of nitric acid and 2mol / L hydrogen peroxide was leached for 8 hours under the condition that the leaching temperature was 70°C and the stirring speed was 200r / min. Then filter and wash with 2mol / L ammonia water, adjust the pH value to 8.2, and dry to obtain carbon powder.

[0055] Put the obtained carbon powder into a muffle furnace for calcination, the protective atmosphere is nitrogen, the temperature is 800°C, and the time is 2.5h. Put the calcined carbon powder into a high-speed kneader, and then add 2 % stearic acid modifier, start the high-speed kneader kneading, the kneading temperature is 150 ℃, and the kneading time is 70min, then transfer to the superfine pulverizer and carry out superfine pulverization, obtain coke carbon bla...

Embodiment example 3

[0058] Take 30kg of petroleum coke in the production process of a domestic factory, the main element content is (wt.%): C 86.56, H 3.396, S 5.602, N 1.3032, O 3.946, crushed to -200 mesh to account for 90%, add 600L of 6mol / L The mixed solution of nitric acid and 2mol / L hydrogen peroxide was leached for 8 hours at a leaching temperature of 75°C and a stirring rate of 200r / min. Then filter and wash with 2mol / L ammonia water, adjust the pH value to 7.7, and dry to obtain carbon powder.

[0059] Put the obtained carbon powder into a muffle furnace for calcination, the protective atmosphere is nitrogen, the temperature is 800°C, and the time is 2h. Put the calcined carbon powder into a high-speed kneader, and then add 2% of the mass of the carbon powder Phosphate ester and titanate modifier whose mass is 1% of carbon powder mass, start high-speed kneader kneading, kneading temperature is 180 ℃, kneading time is 80min, then transfer to superfine pulverizer for superfine pulverizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com