Waterproof and oil-stain-resistant water-based exterior wall paint and preparation method thereof

An exterior wall paint and anti-oil staining technology, which is applied to biocide-containing paints, anti-fouling/underwater coatings, reflective/signal coatings, etc., can solve poor water and oil repellency, adhesion pollution, and poor overall application effect Improve the hydrophobic performance, improve the surface hardness, and improve the water-repellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A waterproof, oil-repellent and sewage-resistant exterior wall paint, the composition and content of raw materials used in its preparation are as follows:

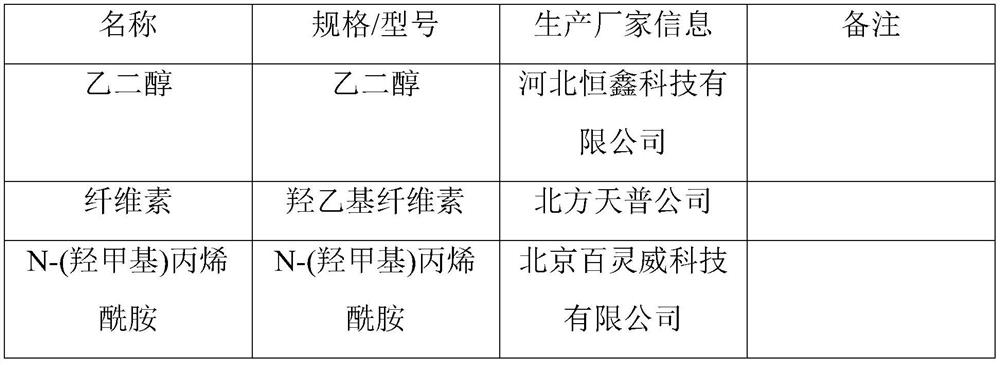

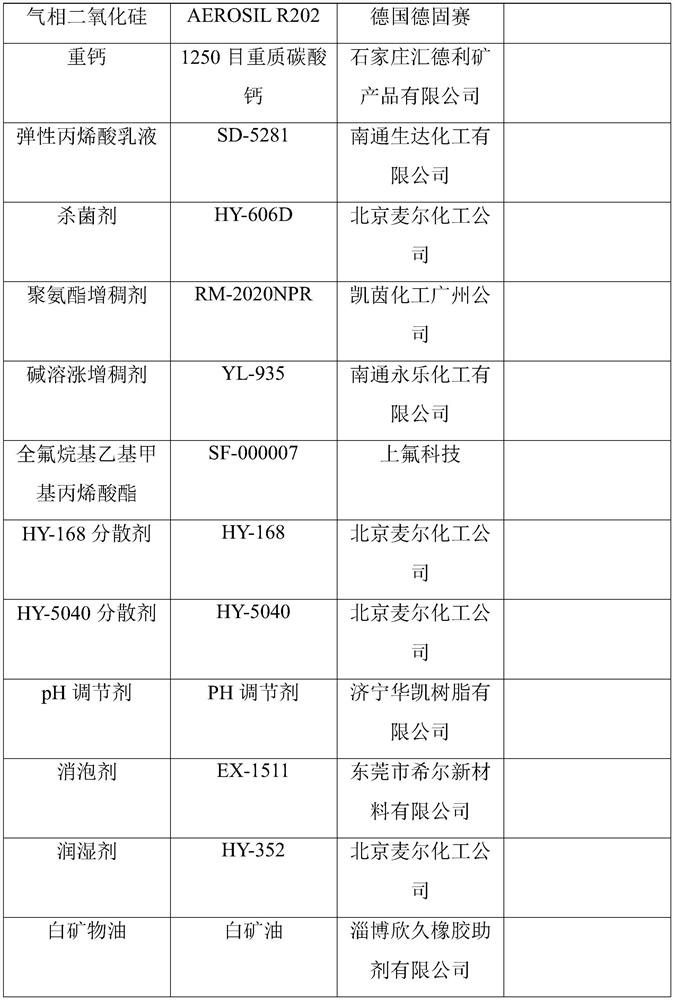

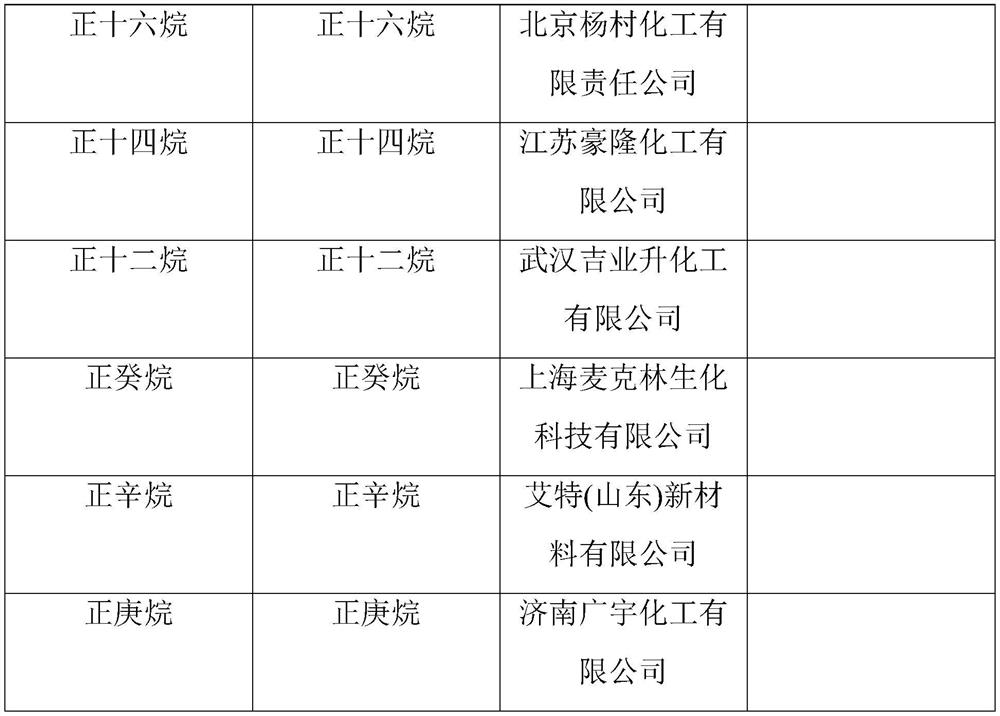

[0056]

[0057]

[0058] Above-mentioned thickener is made up of hydroxyethyl cellulose, polyurethane thickener and alkali-swellable thickener, calculates by weight ratio, namely hydroxyethylcellulose: polyurethane thickener: alkali-swellable thickener is 1: 1.5:1.5(0.26kg:0.4kg:0.4kg);

[0059] The above dispersant is composed of HY-168 dispersant and HY-5040 dispersant. Calculated by weight ratio, HY-168 dispersant: HY-5040 dispersant is 1:1.5 (0.2kg: 0.3kg);

[0060] The above-mentioned other additives are composed of pH regulator, defoamer and wetting agent. Calculated by weight ratio, pH regulator: wetting agent: defoamer is 3:5:6 (0.15kg: 0.25kg: 0.3kg) .

[0061] The preparation method of the above-mentioned a kind of waterproof and oil-repellent sewage exterior wall paint specifically comprises the f...

Embodiment 2

[0067] A waterproof, oil- and sewage-repellent exterior wall paint, which is different from Example 1 in that the amount of raw materials used in the waterproof, oil- and sewage-repellent exterior wall paint is different, as shown in Table 1, and the others are the same as in Example 1.

[0068] The preparation method of above-mentioned a kind of waterproof and oil-repellent sewage exterior wall paint, differs from embodiment 1 in that:

[0069] (1) Mix water, cellulose and N-(methylol) acrylamide, and control the dispersing machine at 200r / min for 3min at a temperature of 100°C to obtain mixture 1;

[0070] (2) Add pH adjuster, 0.15 kg defoamer, and alkali-swellable thickener to mixture 1 in (1), and stir for 4 minutes at a speed of 500 r / min to obtain mixture 2;

[0071] (3) Add wetting agent, HY-168 dispersant, HY-5040 dispersant, ethylene glycol, fumed silica, heavy calcium, perfluoroalkyl ethyl methacrylate to (2) Mixture 2 was stirred at a speed of 1200r / min for 30min t...

Embodiment 3

[0074] A waterproof, oil- and sewage-repellent exterior wall paint, which is different from Example 1 in that the amount of raw materials used in the waterproof, oil- and sewage-repellent exterior wall paint is different, as shown in Table 1, and the others are the same as in Example 1.

[0075] The preparation method of above-mentioned a kind of waterproof and oil-repellent sewage exterior wall paint, differs from embodiment 1 in that:

[0076] (1) Mix water, cellulose and N-(methylol)acrylamide, and control the dispersing machine at 400r / min for 5min at a temperature of 100°C to obtain mixture 1;

[0077] (2) Add pH adjuster, 0.15 kg defoamer, and alkali-swellable thickener to mixture 1 in (1), and stir at a speed of 700 r / min for 6 minutes to obtain mixture 2;

[0078] (3) Add wetting agent, HY-168 dispersant, HY-5040 dispersant, ethylene glycol, fumed silica, heavy calcium, perfluoroalkyl ethyl methacrylate to (2) Mixture 2 was stirred at a speed of 1500r / min for 30min to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com