Preparation method of lithium-sulfur battery electrode material

An electrode material, lithium-sulfur battery technology, applied in battery electrodes, sulfur preparation/purification, lithium storage batteries, etc. Effects of improved chemical properties, enhanced kinetic processes, good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

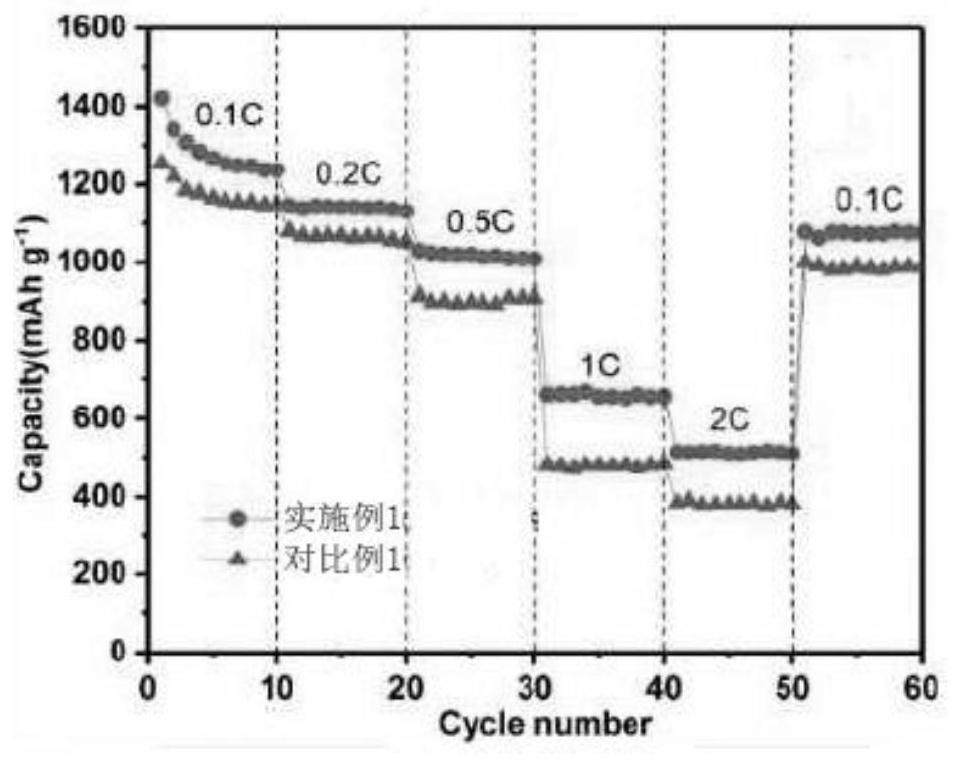

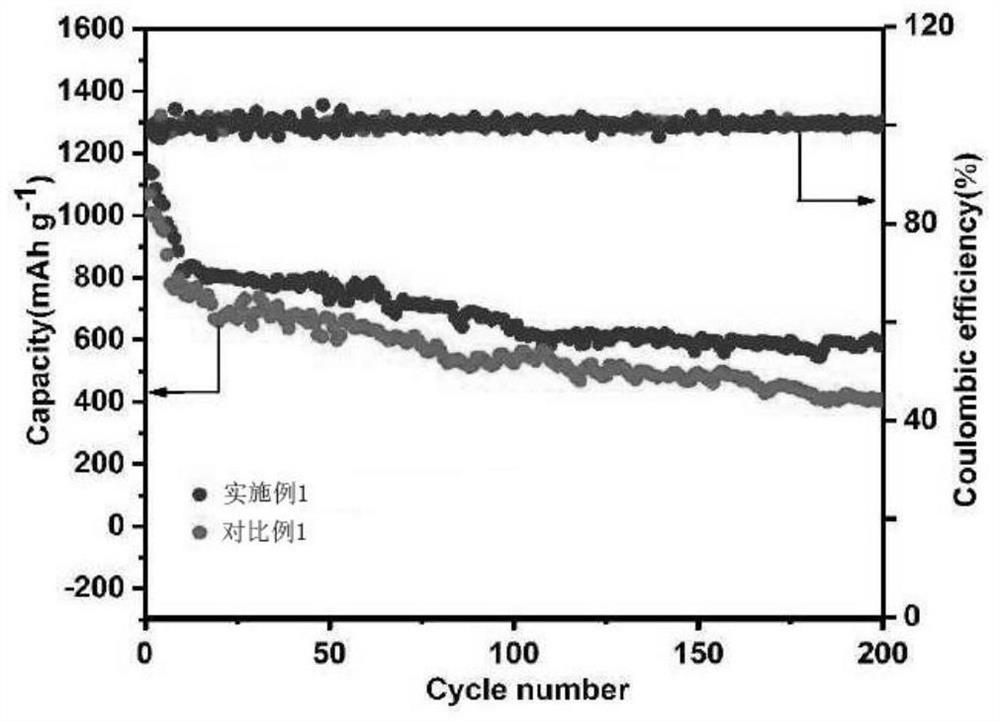

Embodiment 1

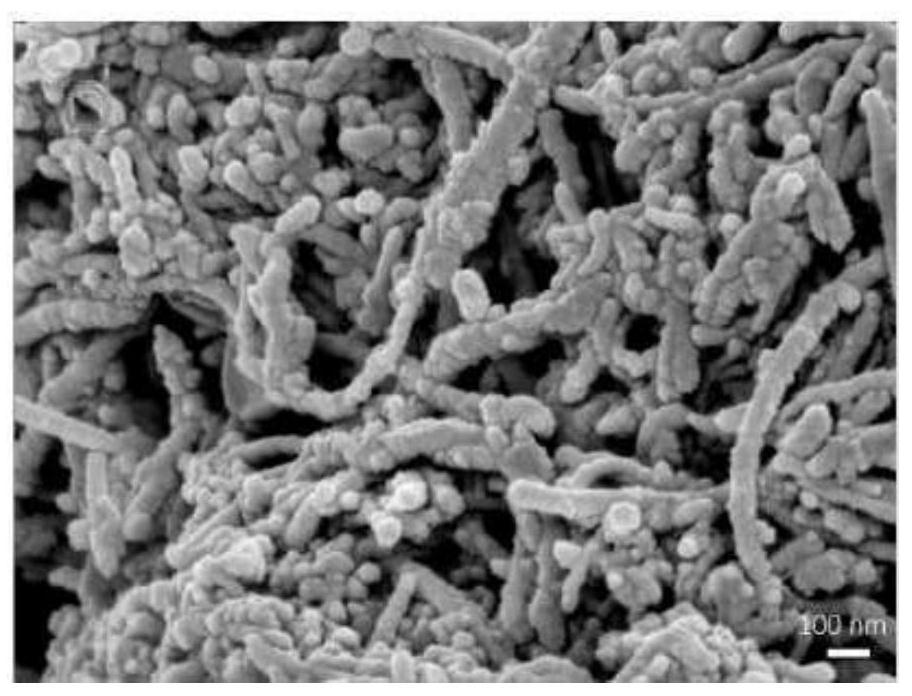

[0023] A preparation method of a lithium-sulfur battery electrode material, specifically comprising the steps of:

[0024] S1: Add cetyltrimethylammonium bromide to anhydrous methanol, ultrasonically dissolve, and then add carbon nanotubes, wherein the mass ratio of cetyltrimethylammonium bromide and carbon nanotubes is 1: 140, continue ultrasonic stirring, and then add cobalt nitrate hexahydrate for ultrasonication to obtain solution A.

[0025] S2: 2-methylimidazole is added to anhydrous methanol solution, ultrasonically obtains a transparent solution B, and then solution A is quickly added to solution B, wherein the mass ratio of cobalt nitrate hexahydrate and 2-methylimidazole is 1: 0.92, the mass ratio of carbon nanotubes to cobalt nitrate hexahydrate was 1:0.35; stirred at room temperature for 3 hours, centrifuged, filtered, washed with ethanol solution 3 times, and dried at 60°C to obtain product Ⅰ.

[0026] S3: Add the product I in step S2 to the absolute ethanol solu...

Embodiment 2

[0030] A preparation method of a lithium-sulfur battery electrode material, specifically comprising the steps of:

[0031] S1: Add cetyltrimethylammonium bromide to anhydrous methanol, ultrasonically dissolve, and then add carbon nanotubes, wherein the mass ratio of cetyltrimethylammonium bromide and carbon nanotubes is 1: 165, continue ultrasonic stirring, and then add cobalt nitrate hexahydrate to obtain solution A.

[0032] S2: 2-methylimidazole is added to anhydrous methanol solution, ultrasonically obtains a transparent solution B, and then solution A is quickly added to solution B, wherein the mass ratio of cobalt nitrate hexahydrate and 2-methylimidazole is 1: 1.06, the mass ratio of carbon nanotubes to cobalt nitrate hexahydrate was 1:0.44; the reaction was stirred at room temperature for 6 hours, centrifuged, filtered, washed with ethanol solution 3 times, and dried at 70°C to obtain product I.

[0033] S3: Add the product I in step S2 to the absolute ethanol solutio...

Embodiment 3

[0037] A preparation method of a lithium-sulfur battery electrode material, specifically comprising the steps of:

[0038] S1: Add cetyltrimethylammonium bromide to anhydrous methanol, ultrasonically dissolve, and then add carbon nanotubes, wherein the mass ratio of cetyltrimethylammonium bromide and carbon nanotubes is 1: 150, continue ultrasonic stirring, and then add cobalt nitrate hexahydrate for ultrasonication to obtain solution A.

[0039] S2: 2-methylimidazole is added to anhydrous methanol solution, ultrasonically obtains a transparent solution B, and then solution A is quickly added to solution B, wherein the mass ratio of cobalt nitrate hexahydrate and 2-methylimidazole is 1: 0.96, the mass ratio of carbon nanotubes to cobalt nitrate hexahydrate was 1:0.38; the reaction was stirred at room temperature for 4 hours, centrifuged, filtered, washed with ethanol solution 3 times, and dried at 60°C to obtain product Ⅰ.

[0040] S3: Add the product I in step S2 to the abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com