Fluorine-containing coating

A kind of coating, Yingdan technology, used in anti-corrosion coatings, fire-retardant coatings, coatings and other directions, can solve the problems of easy powdering, adhesion, poor storage performance, poor weather resistance, peeling, etc., to achieve good high temperature resistance, excellent resistance to salt water. , The effect of good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

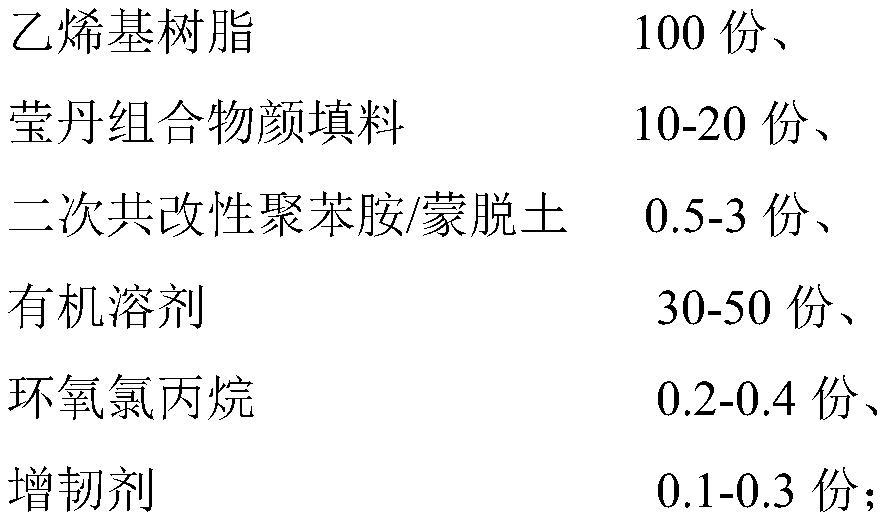

Method used

Image

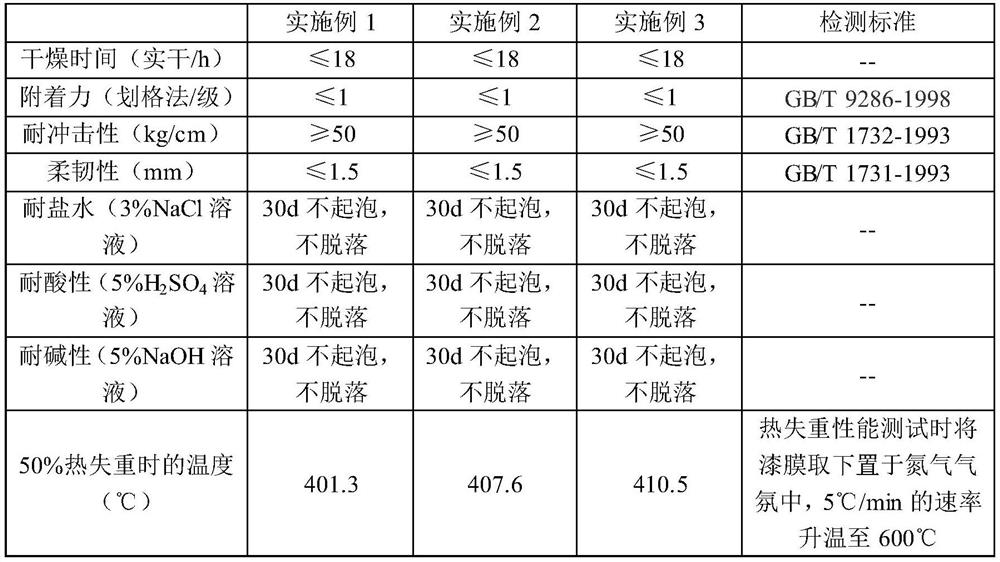

Examples

Embodiment 1

[0033] The preparation method of secondary co-modified polyaniline:

[0034] (1) Add 2g montmorillonite to 2mol / L, 200mL nitric acid aqueous solution, ultrasonically disperse at 22KHz for 0.5h, add 10mL aniline, continue ultrasonically dispersing for 2h, add 25g ammonium persulfate at room temperature, mix and stir fully After the solid precipitate was obtained, it was left to react at room temperature for 24 hours, then washed with water until neutral, then washed with ethanol until the filtrate was colorless, filtered with suction, and dried to obtain a co-modified polyaniline / montmorillonite once;

[0035] (2) Place 1 g of the primary co-modified polyaniline / montmorillonite prepared in step (1) in 0.1mol / L, 100mL ammonia solution, stir well and let stand for 1h, then wash with water until neutral, then wash with ethanol Until the filtrate is colorless, it is suction filtered and dried to obtain polyaniline / montmorillonite;

[0036] (3) Place 1 g of polyaniline / montmorillon...

Embodiment 2

[0047] The preparation method of secondary co-modified polyaniline:

[0048] (1) Add 3g of montmorillonite into 2mol / L, 200mL nitric acid aqueous solution, ultrasonically disperse at a frequency of 22KHz for 1h, add 10mL of aniline, continue ultrasonically dispersing for 3h, add 25g of ammonium persulfate at room temperature, mix and stir fully to obtain After solid precipitation, stand at room temperature for 36 hours, then wash with water until neutral, then wash with ethanol until the filtrate is colorless, filter with suction, and dry to obtain a co-modified polyaniline / montmorillonite once;

[0049] (2) Place 1.5 g of the primary co-modified polyaniline / montmorillonite prepared in step (1) in 0.1mol / L, 100mL ammonia solution, stir well and let stand for 2 hours, then wash with water until neutral, and then ethanol Wash until the filtrate is colorless, filter with suction, and dry to obtain polyaniline / montmorillonite;

[0050](3) Place 1.5g of polyaniline / montmorillonite...

Embodiment 3

[0061] The preparation method of secondary co-modified polyaniline:

[0062] (1) Add 4g montmorillonite to 2mol / L, 200mL nitric acid aqueous solution, ultrasonically disperse at 22KHz for 1h, add 10mL aniline, continue ultrasonically dispersing for 4h, then add 25g ammonium persulfate at room temperature, mix and stir fully to obtain After solid precipitation, stand at room temperature for 48 hours, then wash with water until neutral, then wash with ethanol until the filtrate is colorless, filter with suction, and dry to obtain a co-modified polyaniline / montmorillonite once;

[0063] (2) Place 2 g of the primary co-modified polyaniline / montmorillonite prepared in step (1) in 0.1mol / L, 100mL ammonia solution, stir well and let it stand for 3 hours, then wash with water until neutral, then wash with ethanol Until the filtrate is colorless, it is suction filtered and dried to obtain polyaniline / montmorillonite;

[0064] (3) Put 2 g of polyaniline / montmorillonite prepared in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com