Preparation method of a novel nanofiltration membrane based on zinc hydroxide nanowires

A zinc hydroxide and nanowire technology, applied in the field of nanofiltration membrane technology and water separation, can solve the problems of permeability and selectivity hindering development, poor chemical resistance of nanofiltration membrane, limited service life, etc., and achieve high-efficiency dye desalination. The effect of performance, easy operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

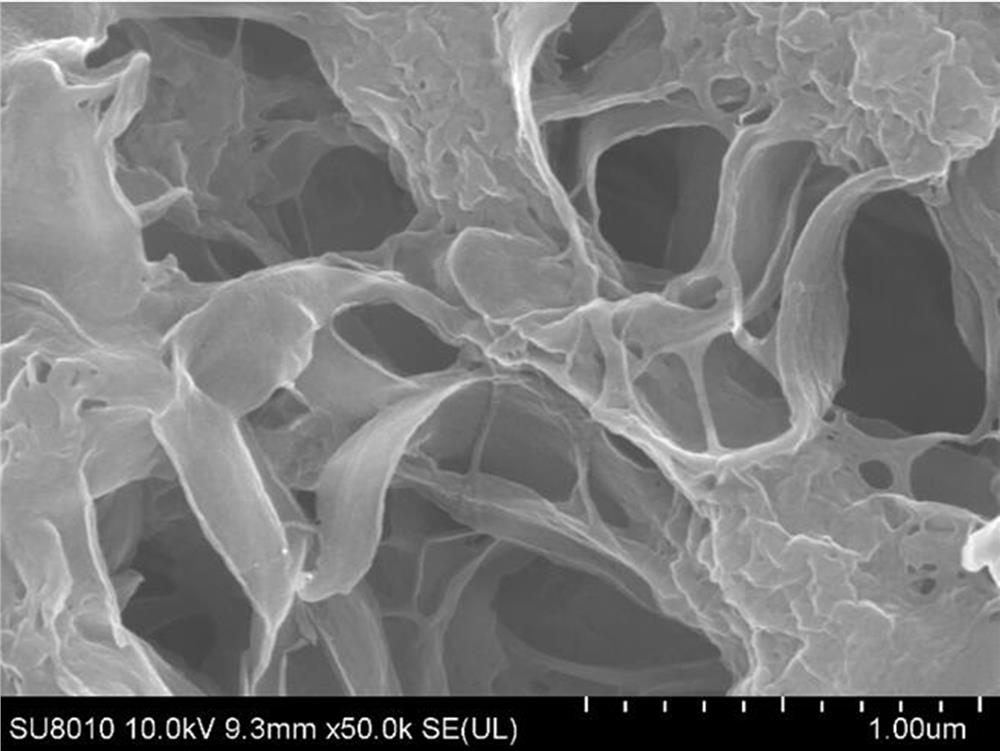

[0029] The polyvinylidene fluoride membrane (PVDF) membrane with an average pore diameter of about 200nm produced by the German Millipore Company is used as the substrate, the effective diameter of the membrane is 5cm, and the solvent used is ultrapure water;

[0030] 1) First, pretreat the PVDF membrane, soak the PVDF membrane in a mixed solution of ethanol and water with a volume ratio of 1:3 to 1:1 for 30-60 minutes, then rinse with pure water 2-3 times for use;

[0031] 2) Mix absolute ethanol and ultrapure water at a volume ratio of 2:3 to accurately prepare 1 L of the mixed solution. Dissolve ethanolamine and zinc nitrate in the mixed solution respectively to prepare a mixed solution of ethanolamine with a concentration of 1.6mmol / L and a mixed solution of zinc nitrate with a concentration of 4mmol / L;

[0032] 3) Take 10 mL of ethanolamine mixed solution and quickly add 10 mL of zinc nitrate mixed solution, stir magnetically at room temperature for 5 minutes and then let...

Embodiment 7-11

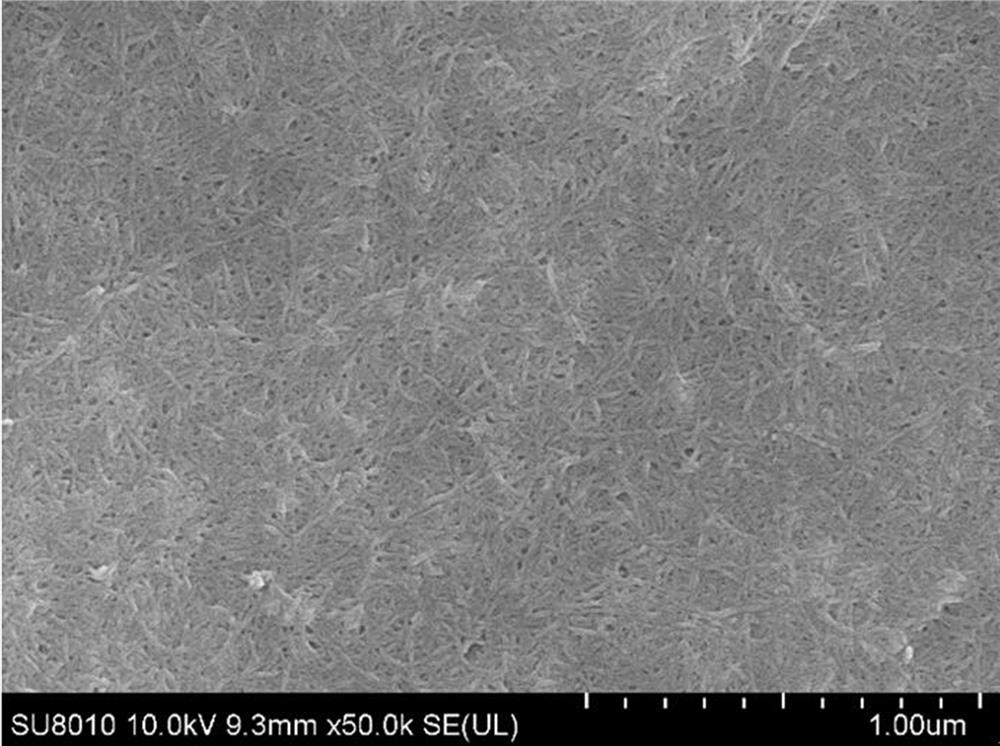

[0038] A polyvinylidene fluoride membrane (PVDF) membrane with an average pore diameter of about 200 nm produced by Millipore, Germany, was used as the substrate, and the effective diameter of the membrane was 5 cm. The solvent used was ultrapure water.

[0039] Like the above-mentioned embodiments, the nanowire thin film prepared by the zinc hydroxide nanowire solution with a volume of 6 mL is preferred. Prepare sodium alginate with concentrations of 0.01%, 0.05%, 0.1%, 0.15%, and 0.2%, and vacuum filter onto zinc hydroxide nanofilm to prepare a new nanofiltration membrane based on zinc hydroxide nanowires. The obtained nanofiltration membrane was tested for dye removal performance in a nanofiltration device. The feed solution was 100mg / L Congo red (Mw=696.66) aqueous solution, the test pressure was 1 bar, and the test temperature was 25°C. The measured removal performance of the nanofiltration membrane to Congo red is as follows:

[0040]

Embodiment 12-16

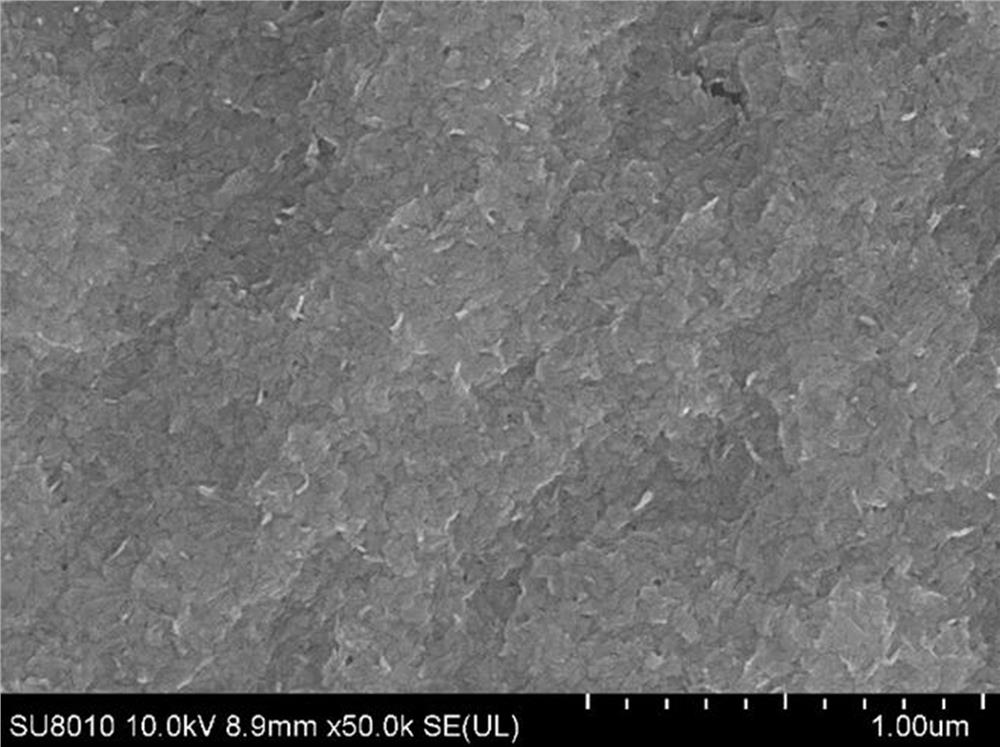

[0042] A polyvinylidene fluoride membrane (PVDF) membrane with an average pore diameter of about 200 nm produced by Millipore, Germany, was used as the substrate, and the effective diameter of the membrane was 5 cm. The solvent used was ultrapure water.

[0043] As in the above examples, a new nanofiltration membrane based on zinc hydroxide nanowires prepared with a concentration of 0.1% sodium alginate is preferred, and the dye removal performance test is carried out in a nanofiltration device. Feed solutions were 100 mg / L methylene blue (Mw=319.85), crystal violet (Mw=407.98), neocarmine (Mw=604.47), Congo red (Mw=696.66) and Coomassie brilliant blue G250 (Mw=858.05) aqueous solution, the test pressure is 1 bar, and the test temperature is 25°C. The measured removal performance of nanofiltration membranes for different dyes is as follows:

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com