Super-hydrophobic surface gas film regulation and control device based on near-wall surface gas saturation regulation

A technology of super-hydrophobic surface and control device, which can be used in devices for coating liquids on surfaces, special surfaces, coatings, etc. Easy to operate, low production cost, simple to produce effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

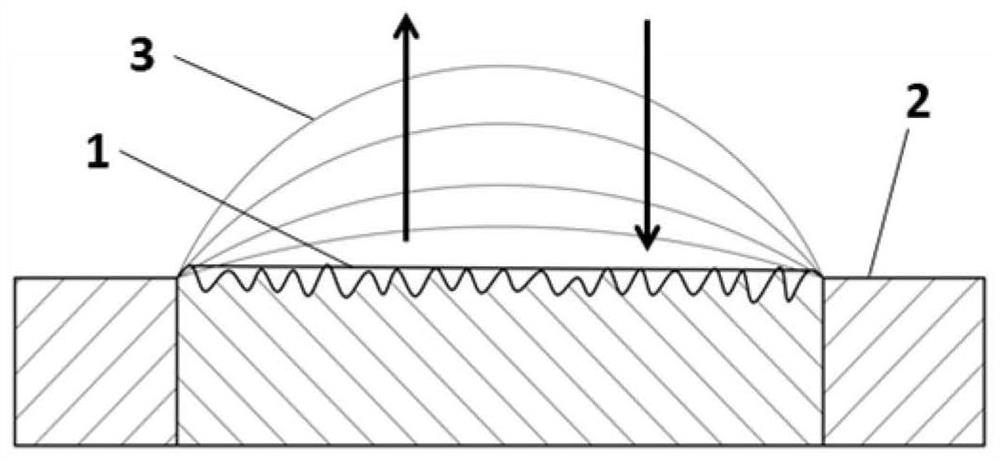

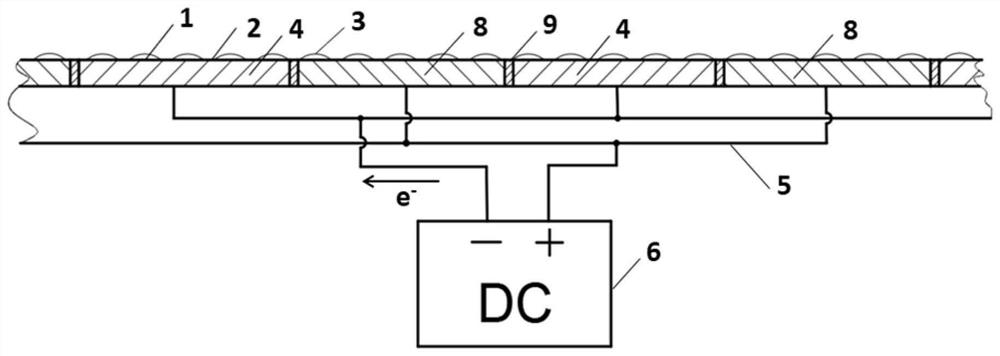

[0043] A device and method for maintaining and regulating the shape of a superhydrophobic surface gas film that uses the principle of electrolytic gas production to adjust the gas saturation near the wall:

[0044] (1) Prepare the base material: use a graphite plate electrode with a size of 50×50mm as the base material, polish the surface of the graphite plate smooth, put the base material in acetone, absolute ethanol and pure water for 30 minutes, and then dry it at a constant temperature Dry in the box at 120°C for 30 minutes to ensure that the electrode wall surface is smooth and has obvious hydrophilicity, and the static contact angle of water droplets is less than 30 degrees.

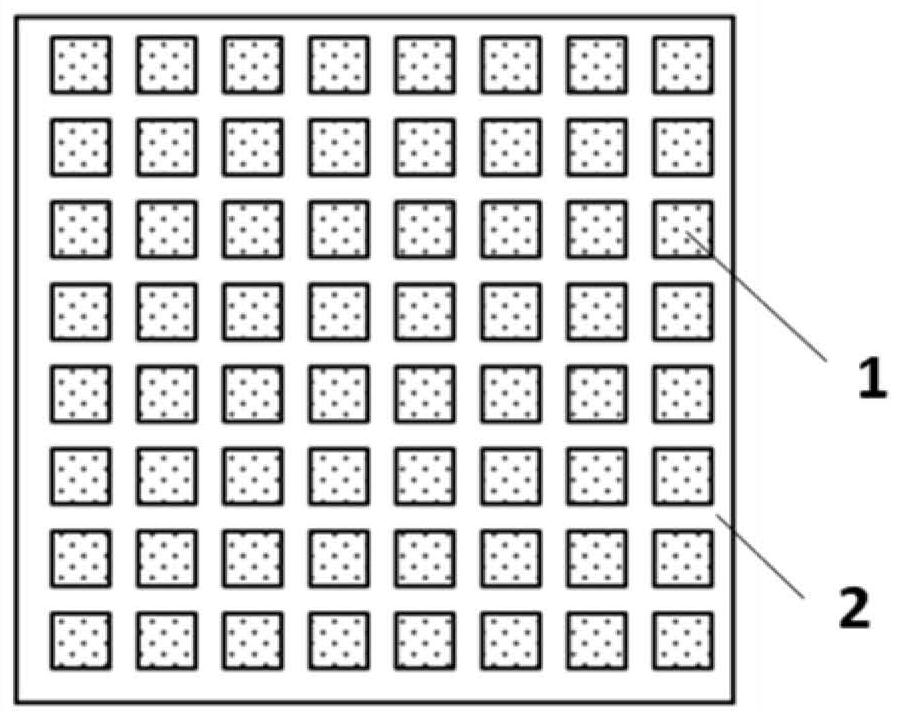

[0045] (2) Make a mask plate, paste a low-viscosity waterproof tape with a width of 1mm on the surface of the electrode, the distance between adjacent parallel tapes is 5mm, and the tapes are alternately arranged in a grid along the horizontal and vertical directions until it is covered. entire sol...

Embodiment 2

[0050] Example 2: A device and method for maintaining and regulating the shape of a gas film on a superhydrophobic surface to adjust gas saturation by means of wall heating:

[0051] (1) Prepare the base material, use a PVC plate with a size of 50×50mm as the base material, polish the surface of the plate smooth, process a checkerboard groove array with a width of 1mm and a depth of 1mm on the surface, and the distance between parallel grooves is 5mm. like image 3 shown. The material was ultrasonically cleaned in acetone, absolute ethanol and purified water for 30 minutes, and then dried in a constant temperature drying oven at 80°C for 60 minutes to ensure that the surface was clean enough to allow the superhydrophobic coating to adhere.

[0052] (2) Arrange thermal resistance wires in the groove, then pour hydrophilic epoxy resin and curing agent into the groove to make the surface of the groove and the surface of the PVC flat plate flush; place the model in a vacuum box a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com