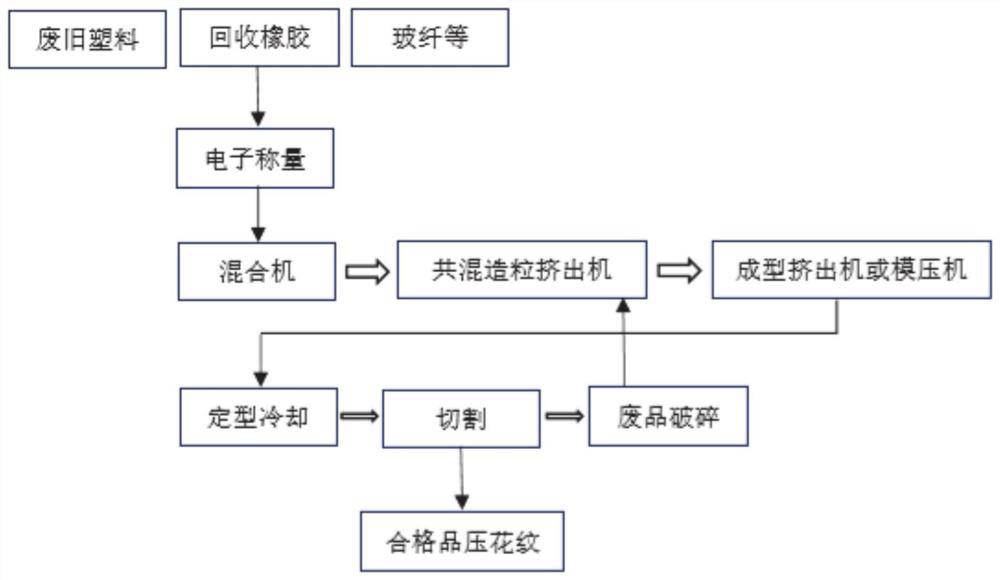

Preparation method and system for thermoplastic plastic-glass fiber extrusion compounded sleeper

A thermoplastic, extrusion compounding technology, used in other household appliances, household appliances, household components, etc., can solve the problems of low output of a single production line, increase production equipment, and single product structure, eliminate secondary pollution, and increase load. Ability, the effect of speeding up the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment adopts the cold top method (cold extrusion method, cold push method, hard top method) to make composite sleepers, specifically:

[0040] Weigh the tailings, chopped glass fiber and resins such as PE or recycled plastics according to the proportion, and automatically feed the materials into the high-speed mixer (200L) for pre-mixing. The temperature of the cooling mixer is 30-50°C, and the rotation speed of the stirring blade is 10-100rpm. Optimum parameters: The temperature of the high-speed mixer is 135°C, the rotation speed of the stirring blade is 1200rpm, the temperature of the cooling mixer is 45°C, and the rotation speed of the stirring blade is 65rpm.

[0041] After premixing, it is transported by tank truck or high-level silo, and is fed into the hopper of the blending and modification extruder by the automatic feeder, and is blended and extruded by a Ф50 flat double extruder for granulation. The temperature of this step is controlled 160-210°C ...

Embodiment 2

[0045] The composite sleeper proposed in this embodiment is produced by banburying+cold top method, as follows:

[0046] Specifically, tailings, chopped glass fiber, PE and other resins or recycled plastics are weighed according to the proportion and added to the internal mixer for blending. After mixing, they are crushed and automatically sent to the Ф65 cone double-molding extruder. (or a single-screw extruder with a diameter of more than 150 mm) is melted and plasticized, and a composite sleeper is obtained through die molding. This step controls the temperature at 155-210° C. (the second step). The composite sleeper enters the shaping mold (the shaping mold is fixed on the reinforced shaping table) for shaping.

[0047] After the shaping is completed, it is automatically cut according to the length required by the customer (such as 2.4 meters, etc.). The following post-processing can also be done according to customer requirements, such as embossing or hob processing patt...

Embodiment 3

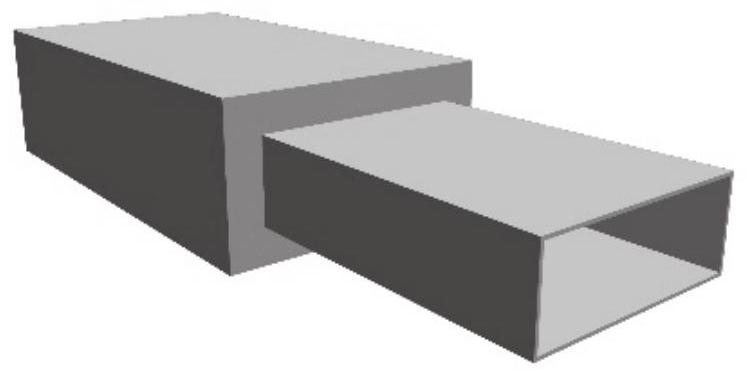

[0052] This embodiment provides a steel (wood) plastic co-extrusion method to make composite sleepers. In order to improve the bending strength and modulus of composite sleepers, steel pipes, square steel or wooden squares, and glass (basalt) fiber tubes are used as composite sleepers. The core material of the sleeper. In particular, square steel and steel pipes also help heat dissipation during extrusion and reduce expansion. The following uses glass (basalt) fiber pipes as an example to illustrate, such as figure 2 As shown, the inner square tube is a glass (basalt) fiber tube or their braided fabric, and the outer square tube is a composite sleeper;

[0053] Composite sleepers are produced by blending and extruding various additives or recycled plastics. Weigh each component according to the proportion, and automatically feed the material into the 200L high-speed mixer (premix). barrel, through Ф50 flat double extruder blending extrusion granulation control temperature 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com