A kind of preparation method of graphitized hierarchical porous carbon

A porous carbon and graphitization technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of harsh process conditions, inability to obtain mesopores, complex process, etc. The ability to adsorb and remove organic pollutants, the effect of high degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

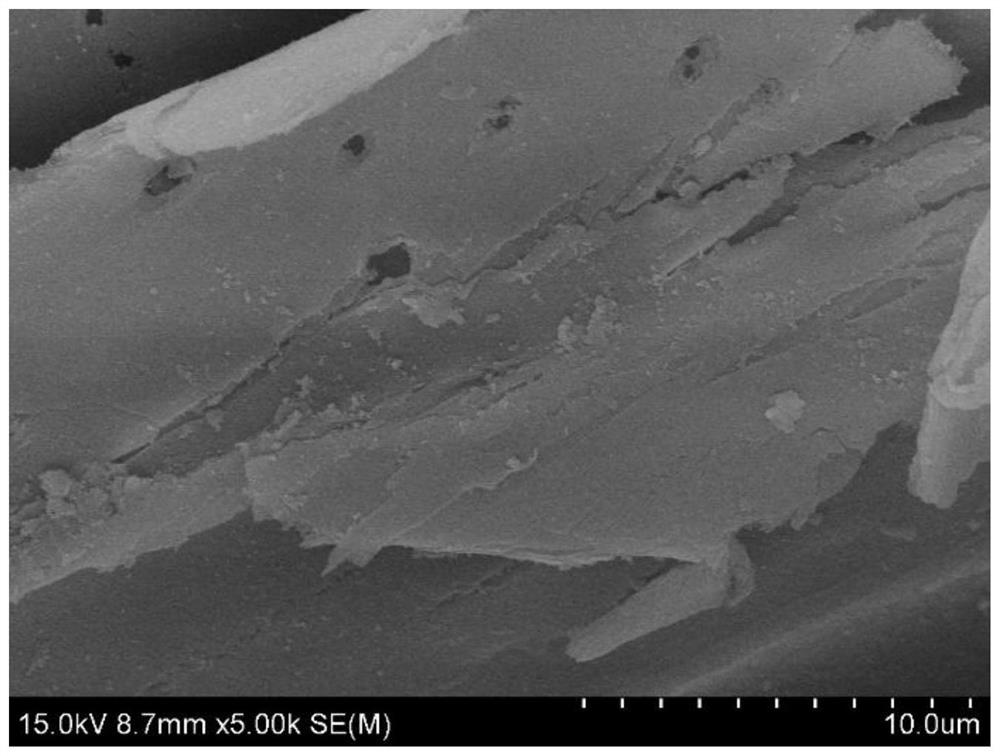

[0031] The preparation method of the graphitized hierarchical porous carbon of the present invention specifically comprises the following steps:

[0032] (1) Preparation of hydrothermal charcoal: first, the cotton stalks were washed with deionized water to remove surface impurities, then the cleaned cotton stalks were dried in an oven at 105 °C for 12 hours, and pulverized with a pulverizer and passed through a 30-mesh sieve to obtain Cotton straw powder; the hydrothermal carbonization experiment was carried out in a high temperature and high pressure reactor. About 10g of cotton straw powder and 60mL of deionized water were put into a quartz tube, and the quartz tube containing the reaction materials was placed in the main reactor. Before the main reactor was finally sealed, the reactor was purged with argon (purity 99.999%) to provide an oxygen-free environment; under autogenous pressure of 1.5-5MPa, the reactor was heated to 200°C at a heating rate of 10°C / min, And the cons...

Embodiment 2

[0038] The preparation method of the graphitized hierarchical porous carbon of the present invention specifically comprises the following steps:

[0039](1) Preparation of hydrothermal charcoal: first, the cotton stalks were washed with deionized water to remove surface impurities, then the cleaned cotton stalks were dried in an oven at 105 °C for 12 hours, and pulverized with a pulverizer and passed through a 30-mesh sieve to obtain Cotton straw powder; The hydrothermal carbonization experiment was carried out in a high temperature and high pressure reactor. About 10g cotton straw powder and 70mL deionized water were put into a quartz tube, and the quartz tube containing the reaction material was placed in the main reactor. Before the main reactor was finally sealed, the reactor was purged with argon (purity 99.999%) to provide an oxygen-free environment; under autogenous pressure of 1.5-5MPa, the reactor was heated to 220°C at a heating rate of 10°C / min, And the constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com