Limestone machine-made sand concrete modifier and concrete containing limestone machine-made sand concrete modifier

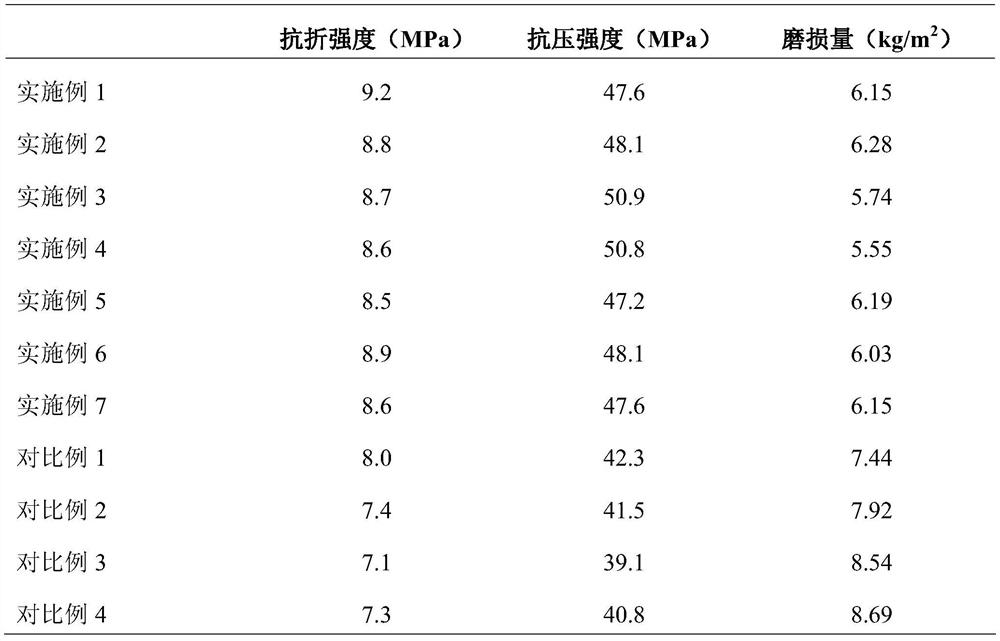

A technology of limestone machine-made sand and concrete modifier, applied in the fields of building material admixtures and road building materials, can solve problems such as poor wear resistance, and achieve the effects of wide application range, low cost, and improvement of compressive and flexural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A limestone machine-made sand concrete modifier is made of the following raw materials in parts by mass:

[0029] 5 parts of nano colloidal silicon dioxide with a solid content of 50%, and 6 parts of lotus leaf type hydrophobic agent.

[0030] A concrete, the quality of the limestone machine-made sand concrete modifier in the concrete is 5% of the cement quality in the concrete, and it only needs to be mixed uniformly.

[0031] The construction method of above-mentioned a kind of concrete comprises the steps:

[0032] 1) Weigh the following components according to the proportion: ordinary Portland cement, limestone machine-made sand, limestone gravel, water, the above-mentioned limestone machine-made sand concrete modifier;

[0033] 2) Add the above-mentioned limestone machine-made sand concrete modifier into the weighed water and stir evenly to form a mixed solution, and then add it into a concrete mixer with other materials to obtain the concrete. (the construction ...

Embodiment 2

[0035] A limestone machine-made sand concrete modifier is made of the following raw materials in parts by mass:

[0036] 6 parts of nano colloidal silicon dioxide with a solid content of 50%, and 7 parts of water-based wax-based hydrophobic agent.

[0037] A concrete, the quality of the limestone machine-made sand concrete modifier in the concrete is 6% of the cement quality in the concrete.

Embodiment 3

[0039] A limestone machine-made sand concrete modifier is made of the following raw materials in parts by mass:

[0040] 7 parts of nano colloidal silicon dioxide with a solid content of 50%, and 4 parts of lotus leaf type hydrophobic agent.

[0041] A concrete, the quality of the limestone machine-made sand concrete modifier in the concrete is 7% of the cement quality in the concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com