Self-healing concrete and preparation method thereof

A concrete and self-healing technology, applied in the field of bio-concrete materials, can solve the problems of high cost of pre-embedded shape memory alloys, high addition of active substances, consumption of active substances, etc., achieve great research value and application potential, and high porosity , the effect of preventing death

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

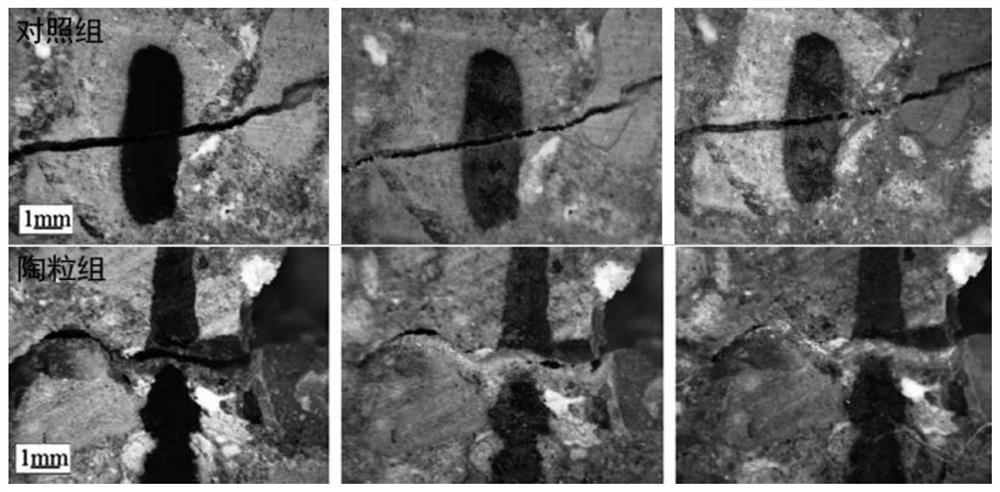

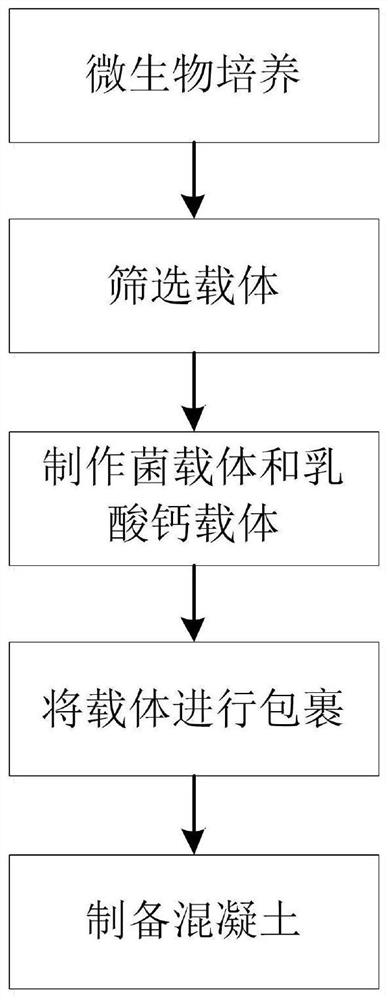

[0026] A preparation method of self-healing concrete, the specific steps are as follows:

[0027] Step 1, select Bacillus pasteurii (Sporosarcina pasteurii, ATCC11859) with mineralization and precipitation function as the lyophilized powder of the thallus, and the thallus should be activated according to the microbial culture method before use;

[0028] Step 2, using the vacuum impregnation method, the mineralized microorganism ATCC11859 Bacillus pasteurianum solution and calcium lactate are adsorbed on the surface and internal pores of the ceramsite particles under negative pressure, dried, and the yeast extract solution is sprayed on the surface of the ceramsite. After completion, it is dried to obtain ceramsite loaded with bacteria and calcium lactate;

[0029] Step 3, evenly spraying a slurry formed by mixing metakaolin, sodium silicate and water on the surface of the ceramsite immobilized with bacteria and calcium lactate, and drying to obtain self-repairing particles;

...

Embodiment 1

[0038] Step 1: The microorganism ATCC11859 Bacillus pasteurianus used in the test was inoculated and cultured according to the routine method of aerobic microorganisms, and the bacillus was cultured in a large amount using a liquid medium. The composition of the medium used was as follows: ultrapure water 1L, peptone 5g , beef extract 3g, sodium carbonate 0.53g, sodium bicarbonate 0.42g, agar powder 18g. Bacillus pasteuriani is an aerobic bacterium, which requires oxygen intake during the growth process. Inoculate the bacteria into a conical flask with a liquid volume of 150mL on the ultra-clean bench, place it in a constant temperature shaker, and The temperature of the shaker was 30° C., and the shaking frequency was 120 r / min, and the culture was carried out at a constant temperature for 24 hours to obtain a bacterial liquid containing Bacillus thallus and spores. Dilute the obtained bacterial liquid with distilled water to an OD600 value of 0.40, and then proceed to the ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com