Preparation method of dopamine sensor material based on Prussian blue/molybdenum selenide

A Prussian blue sensor technology, applied in the field of Prussian blue/molybdenum selenide-based dopamine sensor materials and its preparation, can solve the problems of inconvenient portability, complicated pretreatment, cumbersome steps, etc., and achieve easy functionalization and multiple reaction sites , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

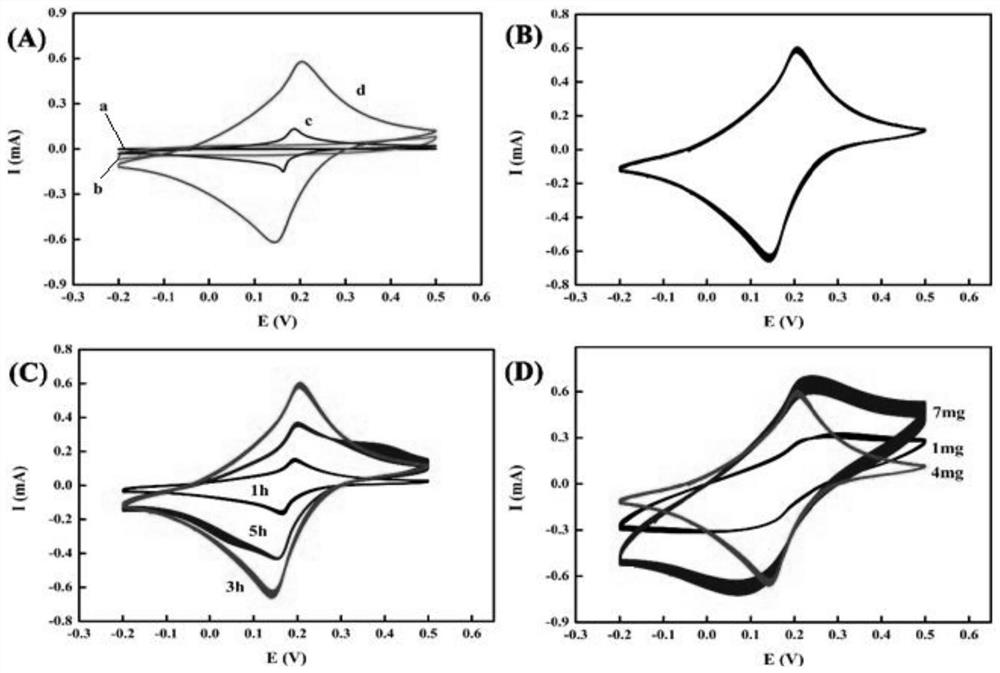

Embodiment 1

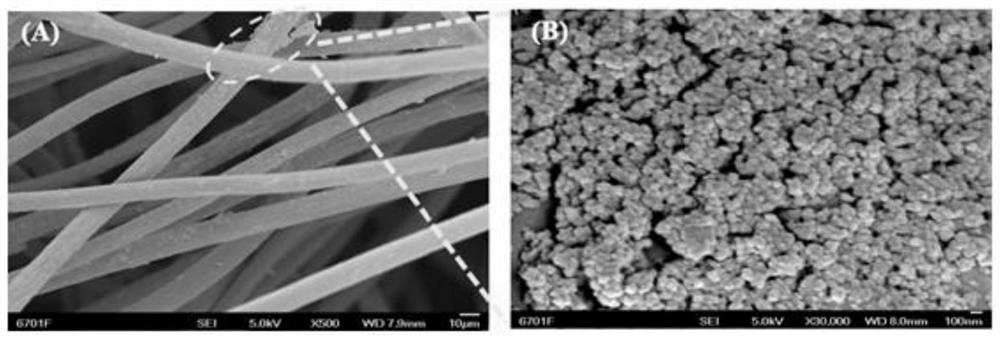

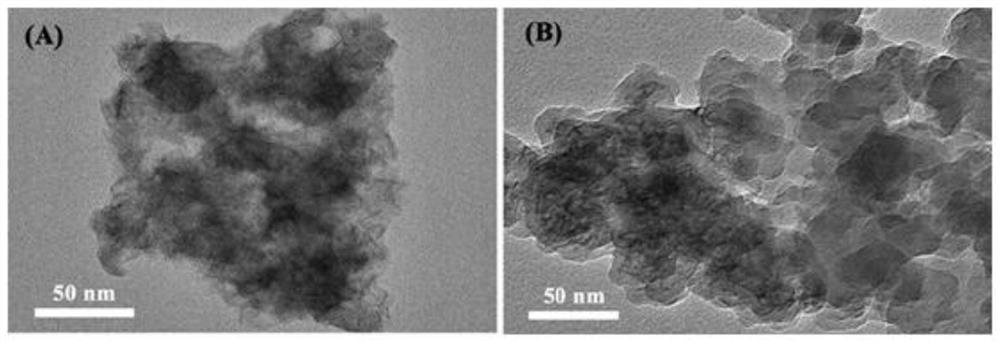

[0036] A PB / MoSe 2 / GF composite electrode material preparation method, the steps are as follows:

[0037] (1) Activate GF

[0038] Cut the polyacrylonitrile-based graphite fiber GF into 2cm×1cm×1mm thin slices, dissolve the viscose on the surface of the cut GF with methanol, and remove the grease on it; then wash it with ultrapure water, alternately until no until scum, 50 ℃ vacuum drying. Select 10 pieces of dried GF and put them into 80mL concentrated nitric acid and reflux at 95-100°C for 3h to enhance the surface roughness and enhance the hydrophilicity of the material, then wash with ultrapure water until neutral, and vacuum dry at 50°C for 12h.

[0039] (2) Preparation of MoSe 2 Nanosheets

[0040] 0.24g Na 2 MoO 4 2H 2O (1mmol), 0.16g Se powder (2mmol) and 0.15g NaBH 4 (4mmol) was dissolved in 30mL ultrapure water. The suspension was ultrasonically dispersed for 10 min and vigorously magnetically stirred for 50 min to obtain a uniform black solution. Subseque...

Embodiment 2

[0048] A MoSe 2 The preparation method of the / GF composite electrode differs from Example 1 in that steps (3) and (4) are omitted; the PB / MoSe in step (5) 2 Replaced by MoSe 2 , the dosage is 1.0 mg; the rest of the steps are the same as in Example 1.

Embodiment 3

[0050] A kind of preparation method of PB / GF composite electrode, and the difference of embodiment 1 is: omit step (2), (4); In step (3), the A liquid of equal volume and containing 2.0mmol / L FeCl 2 , 0.2mmol / L KCl and 0.05mmol / L HCl aqueous solution were mixed and reacted for 12h, centrifuged, washed alternately with ultrapure water and ethanol, and vacuum-dried at 50°C for 12h to obtain the PB material; the PB / MoSe in (5) 2 Replace it with PB powder, the dosage is 1.0 mg; the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com