Preparation method of lactic acid biosensor

A biosensor and lactic acid technology, applied in the field of preparation of lactic acid biosensors, can solve the problems of weak binding force, low stability, difficult electron transmission, etc., and achieve the effects of wide linear range, high repeatability and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

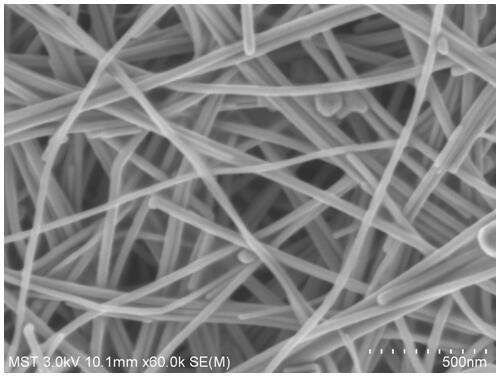

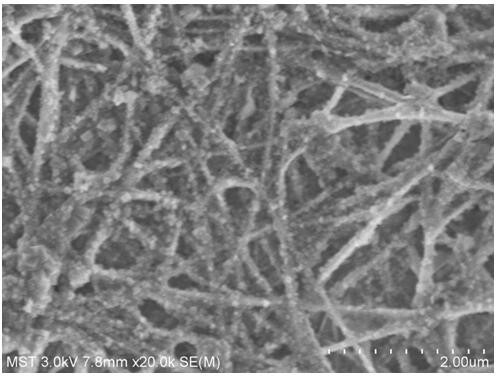

[0024] Polish the gold electrode with polishing powder on metallographic polishing flannelette until the surface is smooth without scratches, ultrasonically treat in deionized water and ethanol respectively, and finally rinse with deionized water. Take 6 μL of copper nanowire solution drop-coated on the polished gold electrode, rinse the electrode surface with deionized water after drying at room temperature. The preparation contains 50mM KCl, 10mM K 3 Fe(CN) 6 , 0.1M hydrochloric acid electrodeposition solution, three electrodes composed of modified electrode, silver / silver chloride reference electrode and platinum counter electrode are immersed in the electrodeposition solution for electrodeposition, and chronoamperometry electrodeposition is performed on the electrochemical workstation. A potential of 0.1V was selected for electrodeposition for 1000 seconds, and the modified electrode after electrodeposition was taken out and rinsed with deionized water. Formulated with 5...

Embodiment 2

[0027] This example is the same as the treatment of copper nanowires and gold electrodes in Example 1, except that 8 μL of copper nanowire solution is drip-coated on the polished gold electrode, and after drying at room temperature, rinse the electrode with deionized water surface. Prepared with 50mM KCl , 50mM K 4 Fe(CN) 6 , 0.1M sulfuric acid electrodeposition solution, chronoamperometry electrodeposition was performed on the electrochemical workstation, and a potential of 0.2V was selected for electrodeposition for 800 seconds, and the modified electrode after electrodeposition was taken out and rinsed with deionized water. Formulated with 8% Nafion ® and 4% BSA lactate oxidase solution, the final enzyme concentration is 150U / mL, take 5 μL enzyme solution and drop it on the surface of the modified electrode, so that the enzyme solution spreads evenly on the electrode surface, and place it in the refrigerator to dry at 4 °C to obtain the lactic acid biosensor.

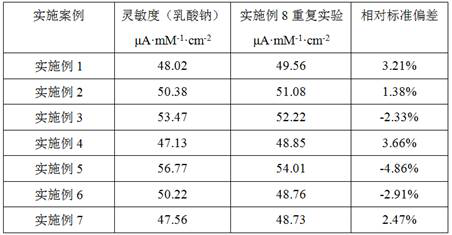

[0028] Co...

Embodiment 3

[0030] This example is the same as the treatment of copper nanowires and gold electrodes in Example 1, except that 10 μL of copper nanowire solution is drip-coated on the polished gold electrode, and after drying at room temperature, rinse the electrode with deionized water surface. Prepared with 50mM KCl , 100mM K 3 Fe(CN) 6 , 0.1M nitric acid electrodeposition solution, chronoamperometry electrodeposition was performed on the electrochemical workstation, and a potential of 0.3V was selected for electrodeposition for 500 seconds, and the modified electrode after electrodeposition was taken out and rinsed with deionized water. Formulated with 10% Nafion ® and 6% BSA lactic acid oxidase solution, the final enzyme concentration is 250U / mL, take 5 μL enzyme solution and drop it on the surface of the modified electrode, so that the enzyme solution spreads evenly on the electrode surface, and place it in the refrigerator to dry at 4 °C to obtain the lactic acid biosensor.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com