Hierarchical hzsm-5 catalyst

A catalyst and layered technology, applied in catalysts, molecular sieve catalysts, carbon compound catalysts, etc., can solve the problems of low yield of cellulose catalytic thermal cracking aromatics, uneven distribution of mesopore pore size, and high yield of thermal cracking aromatics. Good distribution, enhanced heterogeneous mass transfer, and the effect of a large number of mesopores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The first aspect of the present invention provides a kind of preparation method of hierarchical HZSM-5 catalyst, comprises the following steps:

[0024] In the first step, the organic template agent, aluminum source, water, and hard template agent are mixed according to the mass ratio of 1~6: 0.1~1.0: 50~150: 0.1~1.0, stirred to form a mixed solution, and passed into the above mixed solution Gaseous tetraethyl orthosilicate, the temperature is 170~250℃, and the feeding time is 1~12h;

[0025] In the second step, the liquid after the reaction in the first step is stirred, left to stand for aging, transferred to a high-pressure reactor, and reacted in a closed manner at 120-200°C for 1-8 days; the solid product after the reaction is washed, dried, and roasted;

[0026] In the third step, put the product of the second step in 50~90℃, 0.1~2.0mol / L NH 4 Soak in Cl solution for 8~12h, wash, dry, repeat the above process of soaking, washing, and drying 2~4 times, and roast. ...

Embodiment 1

[0040] (1) Mix 10g of tetrapropylammonium hydroxide, 27g of water, 0.3g of sodium metaaluminate, and 0.3g of nanocellulose, and then magnetically stir for 3 hours at room temperature to form a mixed solution. 2 as the carrier, the temperature of TEOS gas is 200°C, the flow rate of TEOS gas is 200mL / min, N 2 The flow rate is 200mL / min, and the feeding time is 6h;

[0041] (2) Stir the reacted liquid from (1), let it stand for aging for 12 hours, transfer it to a high-pressure reactor for crystallization at 170°C for 5 days, wash the reacted solid product, dry it, and roast it at 550°C for 10 hours;

[0042] (3) Put the solid product obtained in (2) in 1.0mol / L NH at 80°C 4 In the Cl solution for 8 hours, carry out ion exchange, filter, wash and dry, repeat the above process twice, and roast at 550°C for 6 hours to obtain the hierarchical HZSM-5 catalyst C1.

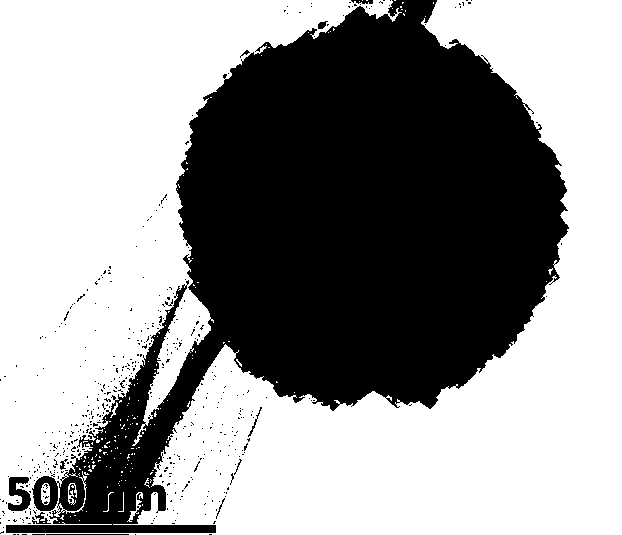

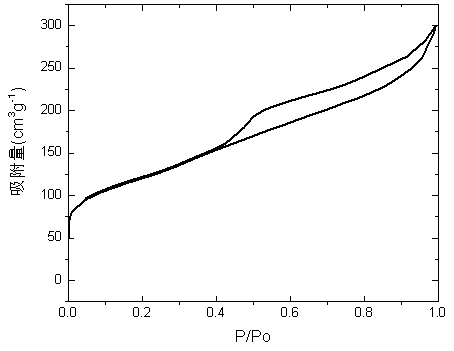

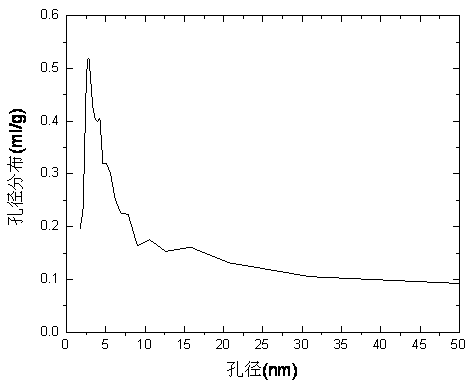

[0043] figure 1 is the transmission electron microscope picture of catalyst C1, figure 1 It can be seen that there...

Embodiment 2

[0047] (1) Mix 10g of tetrapropylammonium hydroxide, 27g of water, 0.3g of sodium metaaluminate, and 0.3g of nanocellulose, and then magnetically stir for 3 hours at room temperature to form a mixed solution. 2 as the carrier, the temperature of TEOS gas is 180°C, the flow rate of TEOS gas is 200mL / min, N 2 The flow rate is 200mL / min, and the feeding time is 6h;

[0048] (2) Stir the reacted liquid from (1), let it stand for aging for 12 hours, transfer it to a high-pressure reactor for crystallization at 170°C for 5 days, wash the reacted solid product, dry it, and roast it at 550°C for 10 hours;

[0049] (3) Put the solid product obtained in (2) in 1.0mol / L NH at 80°C 4 In the Cl solution for 8 hours, perform ion exchange, filter, wash, and dry, repeat the above process twice, and roast at 550° C. for 6 hours to obtain the hierarchical HZSM-5 catalyst C2.

[0050] Catalyst C2 and cellulose were ground and mixed evenly at a mass ratio of 20:1, and the catalytic cracking rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com