A preparation method of three-dimensional microelectrodes for supercapacitors based on carbonization

A technology of supercapacitors and microelectrodes, applied in the field of microelectromechanical systems, can solve the problems of limited capacity space of microsupercapacitors, and achieve the effects of being conducive to integration, increasing the number of mesopores, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

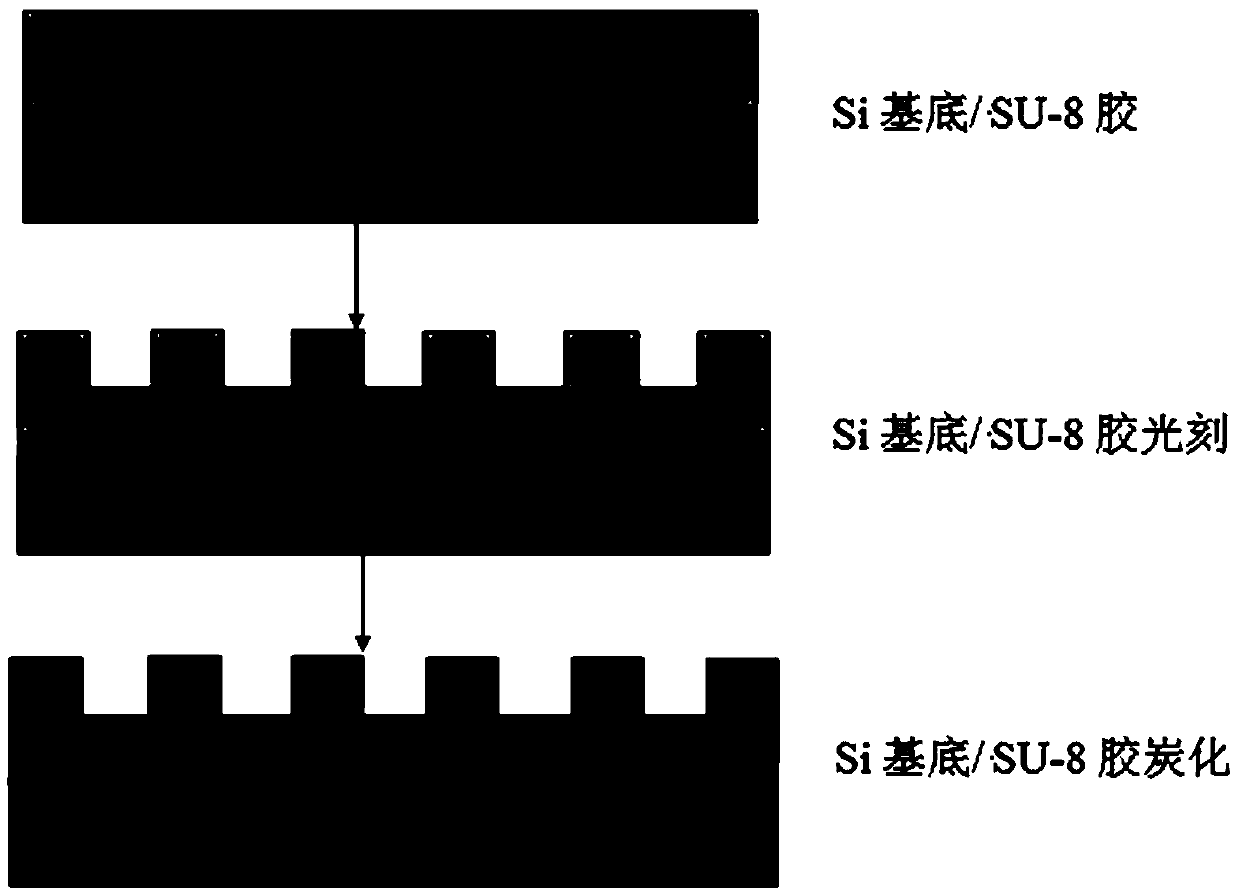

[0018] A method for preparing a three-dimensional microelectrode of a supercapacitor based on carbonization, comprising the following steps:

[0019] (1) Select the silicon wafer as the substrate, wash the silicon wafer in xylene, acetone, alcohol, sulfuric acid / hydrogen peroxide, ammonia / hydrogen peroxide, hydrochloric acid / hydrogen peroxide solution to remove oil, oxide film and metal ions, and then dry;

[0020] (2) Evenly spin-coat SU-8 photoresist on the surface of the silicon wafer after cleaning and drying, and the thickness of SU-8 photoresist reaches 200-500 μm;

[0021] (3) Pre-baking, exposing, post-baking and developing the SU-8 photoresist to obtain a columnar array structure;

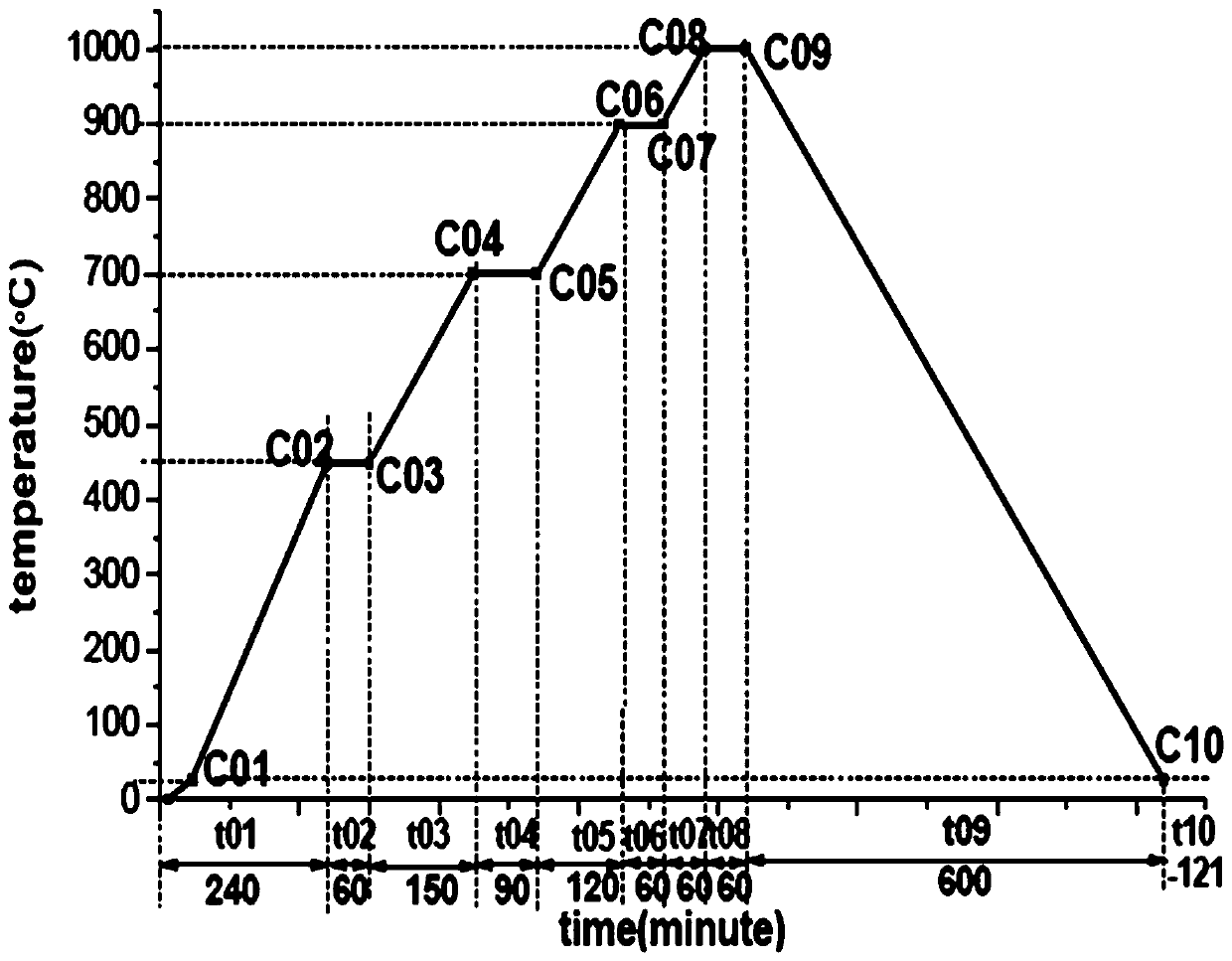

[0022] (4) Put the obtained array structure into a muffle furnace for carbonization. During the carbonization process, the temperature, heating rate and cooling rate are set as follows: First, it takes 240 minutes to raise the temperature from room temperature to 450°C, and the heating rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com